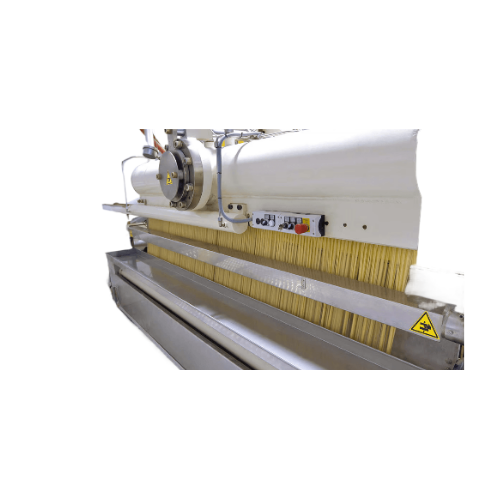

Long-cut pasta production line

Optimize your long-cut pasta production with a single-tier system designed for precise moisture control and consistent quality from extrusion to cooling.

Processes Long-Cut Pasta from Extrusion to Cooling

The Long-cut Pasta Single-Tier Production Line offers a complete solution for pasta producers, incorporating cutting-edge technologies such as TAS and Vacuum technology to streamline the drying and cooling processes. The production line starts with extrusion, followed by pre-drying to eliminate excess moisture, and then transitions to an accelerated drying stage in the TAS HP dryer, ensuring precise temperature and humidity control. This system consistently delivers high-quality spaghetti, fettuccine, and more, by maintaining ideal gluten elasticity through low-temperature vacuum processing and gentle mixing. The stainless-steel dosage and press system, along with integrated spreaders, optimize the mixing and spreading operations while minimizing waste. With a design focused on continuous single-tier operation, this line allows for high-capacity throughput and smooth integration into existing production facilities. Enhanced by a user-friendly PLC interface, maintenance access from both sides, and the inclusion of a stripper saw for precise length cutting, the equipment ensures efficient and reliable long-cut pasta production.

Benefits

- Enhances pasta quality by maintaining optimal gluten elasticity through gentle, low-temperature processing.

- Maximizes production efficiency with precise temperature and humidity control, reducing downtime.

- Increases yield with a system that recycles scraps back into the mixing process.

- Reduces manual labor through easy maintenance access and integrated waste management.

- Supports high-capacity operation with continuous single-tier processing and rapid throughput.

- Applications

- Long-cut pasta, Breakfast cereals, Dry pasta, Snacks

- End products

- Spaghetti, Fettuccine, Bucatini, Vermicelli, Linguine, Tagliatelle

- Steps before

- Extrusion, Pre-drying

- Steps after

- Cooler, Packaging

- Input ingredients

- semolina, water

- Output ingredients

- long-cut pasta

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Dryer Type

- Single-tier

- Dish Capacity

- Full capacity of TAS technology

- Automation

- TAS and Vacuum technology

- Mixing Method

- Slow rotation of mixing paddles

- Spreader Options

- Single or multiple spreader with sticks

- Stick Length

- 1500, 2000, or 2500 mm

- Sensors

- Stainless-steel tank with dough level sensor

- Cooling Access

- Accessible from both sides

- Pre-dryer Function

- Eliminates water from outermost layer

- Drying Process

- Accelerated drying and stabilization

- Working mechanism

- Extrusion, Pre-dry, Dry, Cool

- Integrated steps

- Extrusion, Drying, Cooling

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP compatible

- Energy efficiency

- Optimized for moisture control

- Air incorporation control

- Ventilation units

- Corrosion resistance

- Stainless steel

- Cleanability

- Easy to clean surfaces

- Temperature resistance

- Low temperature operation

- Abrasion resistance

- Smooth surface finish

- Biological compatibility

- Food-grade materials

- Tank material

- Stainless steel

- Discharge method

- Single-tier

- Spreader length

- 1500mm, 2000mm, 2500mm

- Dryer types

- Single-tier dryer, TAS HP dryer

- Control panel type

- PLC-controlled

- Integration possibilities

- TAS technology, Vacuum technology

- Discharge method

- Stripper saw unit for pasta removal and cutting

- Spreader options

- Single or multiple with sticks 1500, 2000, or 2500 mm