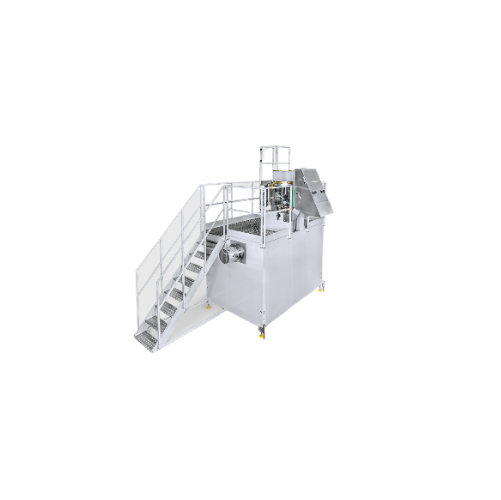

Pasta cutter for short pasta production

Streamline your short pasta production with a versatile cutter designed for rapid format changes, precise cuts, and efficient ventilation, ensuring consistent quality in every batch.

Facilitates Precision Cutting and Quick Die Changes

The Pennaut from GEA is an innovative solution for food production companies looking to streamline pasta and snack manufacturing. Specially designed for short pasta formats like penne and macaroni, it features a robust stainless steel structure with mobility due to integrated wheels. The Pennaut’s precision lifting head ensures seamless cutting mask alignment, reducing product defects. Its high-efficiency cutting and ventilation masks enable rapid die changes, crucial for minimizing downtime in high-speed, continuous operations. An oil hydraulic control unit facilitates precise movement, while chrome-plated steel guides enhance reliability. This equipment offers seamless integration into existing lines and is engineered for easy cleanability, ensuring optimal hygiene.

Benefits

- Speeds up format changes, reducing downtime in high-speed operations.

- Enhances product quality with precise cutting mask alignment, minimizing defects.

- Improves cleanability, decreasing maintenance time and contamination risk.

- Allows for rapid die changes, increasing production flexibility.

- Facilitates mobility and structural durability with stainless steel and wheels.

- Applications

- Snacks, Breakfast cereals, Pasta

- End products

- Rigatoni, Macaroni, Rotini, Snack crackers, Fusilli, Penne pasta, Breakfast cereal flakes

- Steps before

- Mixing, Dough Preparation

- Steps after

- Drying, Packaging, Quality Inspection

- Input ingredients

- short pasta dough, dies for penne, dies for macaroni

- Output ingredients

- penne pasta, macaroni pasta

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Material

- Stainless steel

- Mobility

- Equipped with wheels

- Automation

- Oil hydraulic control unit

- Precision guide

- High precision chrome-plated steel flow guides

- Cutting system efficiency

- Maximum efficiency in terms of ventilation and product flow

- Die change

- Rapid application and removal

- Automation level

- Oil hydraulic control unit

- Transport

- Equipped with wheels

- Cleaning method

- Manual

- Die change

- Rapid application and removal

- Efficiency

- Maximum ventilation and product flow

- Changeover time

- Facilitates and speeds up operations

- Changeover method

- Lifting head adjustment

- Material

- Stainless steel

- Mobility

- Equipped with wheels

- Cleaning and Maintenance

- Easy cleaning and die changes

- Lift System

- Oil hydraulic control unit

- Flow Guides

- Chrome-plated steel

- Lifting heads

- 1T / 2T

- Die configuration

- Various dies or cutting disks for penne and macaroni

- Transportability

- Equipped with wheels