Nest-shaped short pasta production line

Optimize your pasta production with a streamlined process that enhances drying efficiency and maintains nest integrity, ensuring consistent shape and quality in every batch.

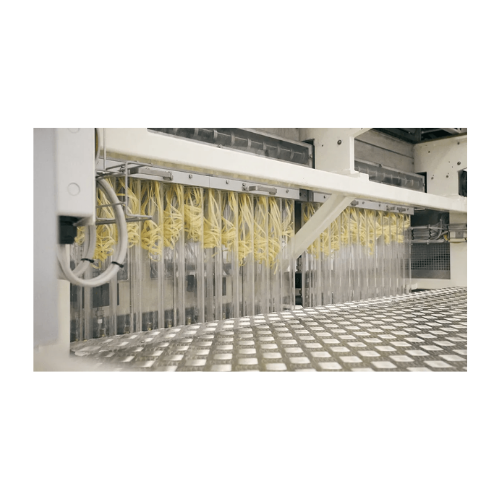

Extrudes, Forms, and Dries Nest-Shaped Pasta

The Nest-Shaped Pasta Production Line: Cups & Belts System is an engineered-to-order solution for pasta manufacturers, designed to handle the intricate processes of extruding, forming, and drying nest-shaped pasta like tagliatelle and fettuccine. This system utilizes a low-shear stainless steel compression screw with variable pitch and broad diameter to ensure gradual dough compression for homogeneous quality. The laminating roller unit and nest forming machine are designed to produce precise and consistent nests, facilitated by 12 or 24 tube options under the press die. Ventilated pre-dryers and conveyors made of stainless steel with mesh bottoms optimize drying efficiency, reducing energy usage by ensuring even air flow. The system is fully automated and integrates seamlessly into existing production lines, offering programmable settings to accommodate different packaging requirements. Constructed from corrosion-resistant materials, it promises durability and long-term performance. The setup meets rigorous hygiene standards, featuring easy-to-clean components to minimize downtime during maintenance.

Benefits

- Enhances production efficiency by minimizing pasta sticking and ensuring optimal texture with precise drying processes.

- Reduces operational costs with energy-efficient ventilation and drying systems.

- Supports flexible production needs with programmable settings for various pasta types and packaging requirements.

- Ensures consistent product quality with homogeneous dough compression and accurate nest forming.

- Simplifies cleaning and maintenance with corrosion-resistant, easily accessible components.

- Applications

- Snacks, Pasta, Noodle products, Breakfast cereals, Dry pasta

- End products

- Fettuccine nests, Linguine nests, Tagliatelle nests, Nest-shaped pasta

- Steps before

- Dough Mixing, Extrusion, Lamination

- Steps after

- Drying, Storage, Packaging

- Input ingredients

- pasta dough, extruded nests

- Output ingredients

- dried pasta nests

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Material

- Stainless steel

- Mesh bottom

- Breathability for drying

- Compression screw type

- Low-shear stainless steel

- Compression screw pitch

- Variable

- Compression screw diameter

- Broad

- Automation

- Automatic sequences for loading/unloading

- Ventilation strength

- Strong

- Laminating roller unit

- Removable

- Nest forming device

- 12 or 24 tubes

- Pre-dryer stages

- Lower and upper dryer

- Dryer section

- Two-stage TAS dryer

- Conveyor belt material

- Stainless steel

- Conveyor tube material

- Transparent food grade

- Drying process

- In cups and on belts

- Working mechanism

- Extrusion, pre-drying, drying

- Integrated steps

- Pre-drying, drying, storing

- Batch vs. continuous operation

- Batch

- Automation level

- Manual / PLC

- Control system

- Programmable presets

- Cleaning method

- Manual

- Energy efficiency

- Enhanced due to mesh bottom in cups and belts

- Product shape

- Nest-shaped

- Process type

- Continuous

- Belt type

- Stainless steel with mesh bottom

- Nest shape

- Extruded

- Conveyor mechanism

- Belts