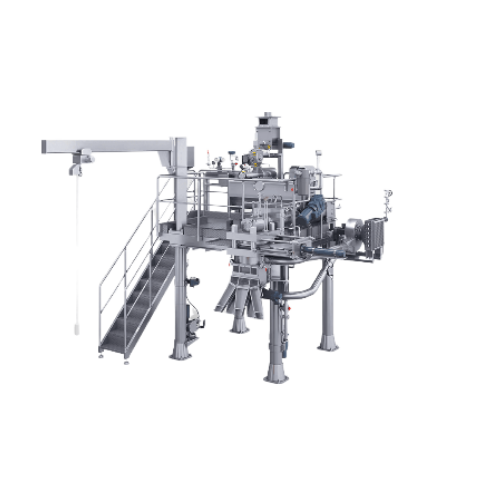

Continuous automatic pasta extruder

This state-of-the-art extruder simplifies your pasta production by seamlessly integrating mixing, kneading, and extrusion processes, ensuring consistent quality and reducing manual intervention.

Processes and Extrudes Diverse Pasta Shapes

The GEA xTru Former is a versatile pasta extrusion machine from GEA, designed to optimize your food production processes. This equipment excels in the continuous mixing, kneading, and extrusion of pasta, snacks, and breakfast cereals, producing a range of end-products such as penne, fusilli, and lasagna sheets. With a processing capacity ranging from 80 to 3100 kg/h, it efficiently meets the demands of food processors and pasta manufacturers. Operating at a low-speed extrusion rate of 25 rpm, the machine ensures gentle product handling, enhancing the quality of your final products. Its fully stainless-steel construction provides robust performance and easy maintenance, while features like automatic die change and temperature-controlled extrusion enhance operational efficiency. The xTru Former supports integration into existing lines with automatic controls and the option for vacuum processing, promoting seamless and energy-efficient operations.

Benefits

- Enhances product quality with gentle processing at low extrusion speeds.

- Increases operational efficiency through automatic die changes and temperature control.

- Simplifies maintenance with easy access to components and automatic screw extraction.

- Flexibly adapts to diverse pasta shapes, meeting varied production needs.

- Robust stainless-steel design ensures long-term durability and hygiene compliance.

- Applications

- Lasagna, Snacks, Pasta, Short-cut pasta, Fresh pasta, Breakfast cereals, Sheet pasta

- End products

- Spaghetti, Lasagna sheets, Penne pasta, Rigatoni, Fettucine, Tortellini sheets, Ravioli sheets, Cannelloni tubes, Fusilli, Tubetti pasta

- Steps before

- Mixing, Kneading, Ingredient Feeding

- Steps after

- Cooling, Heating, Cutting, Packing

- Input ingredients

- main ingredients, mixture

- Output ingredients

- short-cut pasta, sheet pasta, lasagna, pasta shapes, penne, tubetti

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Capacity

- 80–3100 kg/h

- Automation

- Continuous automatic

- Speed

- 25 rpm

- Extrusion type

- Short-cut pasta, sheet pasta, lasagna

- Cooling/Heating Circuit

- Yes

- Cutter Types

- Slant cut (penne), Orthogonal cut (tubetti)

- Working Mechanism

- Mixing, Kneading, and Extrusion

- Automation Level

- Automatic

- Batch vs. Continuous Operation

- Continuous

- Cleaning Method

- Automatic Extraction

- Extrusion Speed

- 25 rpm

- Corrosive resistance (e.g. acids)

- Yes

- Abrasion resistance

- Yes

- Machine placement

- Stainless-steel terrace

- Material

- Stainless steel

- Extrusion screw

- Automatic extraction

- Cover type

- Opening cover with safety switch

- Paddles

- Fixed using a conical joint

- Cooling/heating circuit

- Provided for both extrusion cylinder and heads

- Cutter type

- Slant cut (penne) / Orthogonal cut (tubetti)

- Construction material

- Stainless steel

- Extrusion cylinder features

- Cooling/heating circuit

- Extrusion die change

- Automatic

- Product feed system

- Integrated with previous machine

- Vacuum option

- Total vacuum version available

- Cutting options

- Slant cut (penne) or orthogonal cut (tubetti)

- Screw extraction

- Automatic

- Control panel type

- Not specified

- Integration possibilities

- Facilitated feeding for next machine