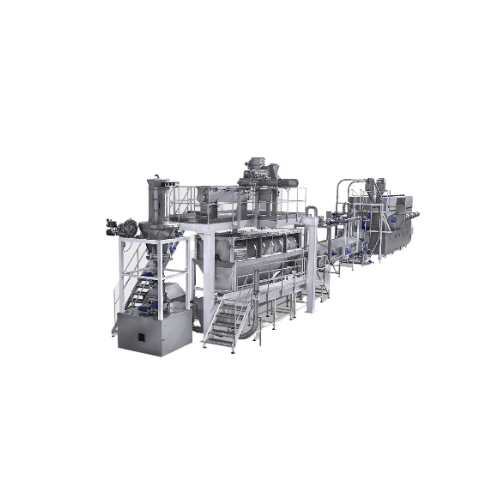

Couscous production line

Enhance your couscous production with a seamlessly integrated line that ensures precise granule sizing, even cooking, and efficient drying, delivering consistent, high-quality results.

Calibrates, Cooks, Mixes, and Dries Couscous

The Couscous Production Line from GEA efficiently calibrates, cooks, mixes, and dries couscous, addressing the unique challenges faced by food manufacturers. Utilizing a stainless steel mesh for calibration, it ensures precise sizing and separation of granules. The steam cooker uses minimal energy by injecting vapor from below, cooking the granules evenly on a conveyor belt while preventing clustering with two crushing axles. The rotary dryer operates over a broad temperature range up to 130°C, continuously moving granules to maximize airflow and rapidly dry them, all while featuring a zero-loss recycling system. This equipment is designed for seamless integration into high-speed, continuous operations in food processing and is available with options for enhanced cleaning and maintenance, ensuring longevity and operational efficiency.

Benefits

- Enhances production efficiency with continuous, high-speed operation.

- Ensures uniform couscous quality by preventing clustering and maintaining consistent granule size.

- Reduces energy usage through optimized steam cooking and drying processes.

- Simplifies maintenance with easy-to-clean design and stainless steel components.

- Supports sustainable production with a zero-loss product recovery system.

- Applications

- Snacks, Breakfast cereals, Pasta

- End products

- Couscous

- Steps before

- Mixing ingredients, Dough preparation

- Steps after

- Packing, Distribution

- Input ingredients

- semolina, water, grains

- Output ingredients

- couscous, cooked couscous, gelatinized couscous

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Calibration Rollers

- Stainless steel mesh

- Steam cooker

- Energy-efficient vapor injection

- Rotary dryer

- Up to 130°C

- Automation

- PLC-controlled

- Product Recovery

- Zero loss

- Working mechanism

- Calibration rollers, steam cooker, rotary dryer

- Integrated steps

- Separation, cooking, drying

- Batch vs. Inline operation

- Continuous inline

- Energy efficiency

- High efficiency with minimal energy usage

- Cleaning method

- Facilitated by stainless steel mesh for easy maintenance

- Automation level

- Automated with calibration and mixing operations

- Airflow efficiency

- Maximized through the structure of rotary dryer

- Abrasion resistance

- Yes

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel

- Density/particle size

- Adjustable by size calibration

- Feed/discharge method

- Conveyor belt

- Outer structure material

- Stainless steel

- Roller material

- Stainless steel mesh

- Steam cooker orientation

- Horizontal

- Dryer type

- Rotary

- Roller Structure

- Stainless steel mesh

- Steam Cooker Type

- Vapor injection

- Dryer Temperature Range

- Up to 130 °C

- Product Recovery,Recycling System

- Reduces losses to zero