Industrial die washing solution for pasta production

Enhance efficiency in pasta and snack production with a robust die washing system, ensuring optimal cleanliness and reduced downtime between production runs.

Cleans and Filters Pasta and Snack Dies

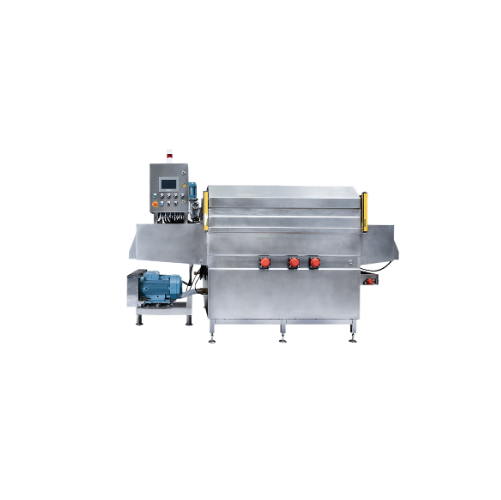

The GEA Universal Die-Washer by GEA Group is engineered to optimize the cleaning of dies within food production lines, particularly in pasta and snack manufacturing. It features both electromechanical and PLC control options, allowing for precise timing and customization of washing cycles. This unit accommodates dual die operation, enhancing efficiency and throughput. Designed with a robust stainless steel frame, it withstands the rigors of industrial environments, while the integrated automatic water level control and skimming removal system ensure effective operation with minimal downtime. Ideal for a variety of pasta shapes, including intricate designs like animal forms, it incorporates a debris conveying system and double filtering for superior water recycling. Additionally, maintenance-free electric cylinders drive the washing arms, reducing the need for regular servicing and maintaining consistent performance in demanding settings.

Benefits

- Enhances production efficiency by accommodating simultaneous dual die washing.

- Minimizes need for manual intervention with PLC-controlled, customizable washing cycles.

- Extends equipment lifespan with maintenance-free electric cylinder operation.

- Improves water conservation through advanced recycling and debris filtration systems.

- Supports diverse pasta shapes, increasing flexibility in product offerings.

- Applications

- Snacks, Breakfast cereals, Pasta

- End products

- Shaped pasta like animals or cartoon characters, Lasagne, Spaghetti, Conchiglie, Penne

- Steps before

- Pasta Production, Dies and Moulds Preparation, Format Change Operations

- Steps after

- Sterilization, Packing

- Input ingredients

- dies, water

- Output ingredients

- cleaned dies, recycled water, debris

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Control System

- Electromechanical / PLC

- Washing Capacity

- Up to 2 dies

- Control Panel

- Intuitive

- Washing Area Regulation

- Adjustment levers

- Cycle Duration Control

- Timer

- Electric Cylinder

- Maintenance-free

- Frame Material

- Stainless Steel

- Debris Conveying System

- With water temperature control

- Water Level Control

- Automatic

- Water Recycling

- Double filtering device

- Skimming Removal System

- Programmable water jets

- Die Types

- Rectangular / Round

- Automation level

- Manual / Electromechanical / PLC

- Cleaning method

- Manual / Automatic

- Die handling capacity

- One or Two dies

- Control panel type

- Intuitive / PLC

- Washing cycle duration

- Set by timer

- Washing arms movement

- Electric cylinder-driven

- Water level control

- Automatic

- Temperature control

- Probe-equipped

- Water recycling

- Double filtering device

- Skimming removal

- Programmable water jets

- Corrosive resistance (e.g. acids)

- Stainless steel

- Machine footprint

- Not specified

- Frame material

- Stainless steel

- Control panel type

- Intuitive for Type M, PLC for Type E

- Adjustment levers

- Located in front of the machine

- Debris conveying system

- Includes water temperature control

- Recovery tank

- Double filtering device

- Washing arms movement system

- Electric cylinder

- Control panel type

- Intuitive control panel or PLC

- Die washing recipe storage

- Available with PLC model

- Washing area regulation

- Adjustment levers

- Washing cycle duration setting

- Timer