Heating system for sustainable moulded pulp packaging

Maximize material efficiency and sustainability by ensuring consistent heating and lamination of thin polymer films on fiber-based packaging, providing robust barriers and thermal insulation in eco-friendly and recyclable packaging solutions.

Laminates and Heats Fiber-Based Packaging

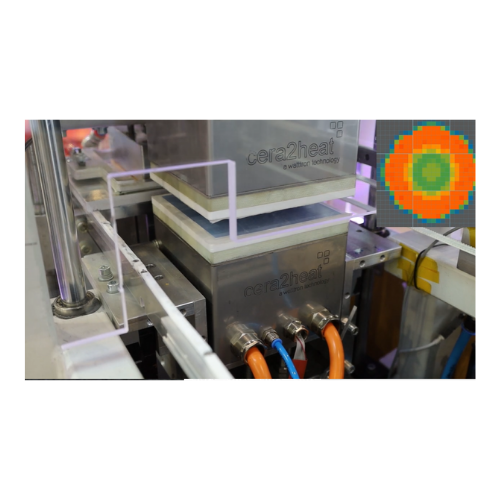

The cera2heat Digital Heating System from watttron is tailored for packaging manufacturers focusing on sustainable solutions. It distinguishes itself by using an innovative digital heating technology that ensures uniform lamination of thin plastic films into molded fiber packaging. This system excels in continuous, high-speed operations ideal for creating products like fiber trays, coffee cup sleeves, and biodegradable bowls.

The system employs precise, modular heating elements that can heat up to 100 K/s and maintain temperatures up to 200°C. Integrated sensors allow for optimal process control and temperature regulation, making it suitable for materials with narrow processing windows like polypropylene.

In addition to energy efficiency, leveraging thinner films results in significant cost reduction. The system can be seamlessly integrated into existing production lines, featuring a user-friendly GUI or integration with machine control systems. This digital heating innovation provides an eco-friendly manufacturing edge, essential for sustainable packaging and recycling industries.

Benefits

- Enhances sustainability with recyclable, fiber-based packaging solutions.

- Reduces energy consumption through efficient, precise heating elements.

- Decreases production costs by using thinner laminate films.

- Simplifies integration with existing lines, improving operational flexibility.

- Supports high-speed production, minimizing bottlenecks and increasing output.

- Applications

- Sustainable packaging, Beverage packaging, Recyclable packaging, Food packaging, Fiber-based packaging, Moulded packaging

- End products

- Eco-friendly packaging inserts, Plant-based packaging wraps, Coffee cup sleeves, Compostable plates, Takeaway beverage cups, Food trays, Biodegradable bowls, Fiber trays, Food containers, Recyclable clamshell boxes

- Steps before

- Laminating plastic film, Preparing faserbasierte (fiber-based) form packaging

- Steps after

- Recyclable packaging, Separation of components for disposal, Packing

- Input ingredients

- faserbasierte Formverpackungen, Kunststofffolie, Polypropylen, recycelte Kunststoffe

- Output ingredients

- gleichmäßige Materialverteilung, dünne Schicht Kunststofffolie, recycelbare Verpackung, Wärmeisolierung

- Market info

- Heating Rate

- up to 100 K/s

- Temperature Range

- up to 200°C

- Power Density

- up to 50 W/cm²

- Module Size

- 40 mm × 40 mm

- Heating Pixel Size

- 5 mm × 5 mm

- Heating Area

- practically unlimited (modular concept)

- Working mechanism

- Digital heating technology

- Integrated steps

- Laminating

- Batch vs. continuous operation

- Continuous

- Energy efficiency

- Energy savings with thinner films

- Automation level

- Integrated with user interface (GUI) or machine control

- Changeover time

- Production-ready in few seconds

- Polymer compatibility

- Polypropylene

- Polymer compatibility

- Recycled plastics

- Layering compatibility

- Fiber-based packaging

- Density/particle size

- 80-150 µm

- Control panel type

- User Interface / GUI

- Compact footprint

- Yes

- Control panel type

- Integrated with GUI

- Integration possibilities

- Integration with machine control systems

- Heating module size

- 40 mm × 40 mm (8×8 Heizpixel)

- Heating pixel size

- 5 mm × 5 mm

- Modular concept

- Practically unlimited heating area