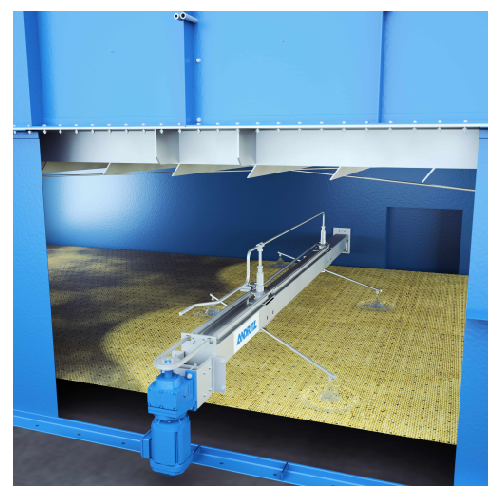

Belt dryer cleaning system

Maximize drying efficiency and product quality with an advanced belt-washing system designed to enhance performance and longevity of belt dryers through optimal cleaning and reduced high-pressure water use.

Maximizes Drying Efficiency and Cleans Belt Dryers

The SmartCLEAN from ANDRITZ revolutionizes belt dryer maintenance with its innovative belt-washing technology. Designed for industries including biofuel, marine, and recycling, it enhances drying efficiency by ensuring product uniformity across dryer belts. The system operates using a rotating design that minimizes high-pressure water usage while extending belt life through optimal cleaning. Ideal for drying biomass pellets, sludge cakes, and textiles, SmartCLEAN supports continuous, automated operations integral to high-efficiency production lines. Easily retrofit onto existing equipment, this device simplifies maintenance with standard spare parts, significantly reducing downtime and increasing throughput.

Benefits

- Enhances product quality with uniform dryness across the belt.

- Minimizes water usage, cutting operational costs.

- Extends belt lifespan, reducing replacement frequency.

- Facilitates quick integration with existing systems, improving uptime.

- Lowers maintenance effort with easy access and standard parts.

- Applications

- Marine offshore, Separation technologies, Nonwoven and textile, Belt dryers, Biofuel, Environmental solutions, Recycling

- End products

- Dried algae, Dehydrated food products, Cotton fibers, Compost granules, Dried sludge cakes, Geotextiles, Dried biomass pellets, Sailcloths, Sewage sludge chips, Recycled plastic flakes

- Steps before

- Material loading, Pre-treatment

- Steps after

- Product cooling, Quality inspection

- Input ingredients

- moist materials, wet products

- Output ingredients

- dried materials, stable product dryness

- Market info

- ANDRITZ is known for its expertise in supplying industrial ETO equipment and services, specializing in sectors like pulp and paper, hydropower, and metals. It has a strong reputation for innovation and engineering excellence.

- Drying Efficiency

- Maximum

- Belt Cleaning Method

- Improved rotating design

- Water Usage

- Minimal high-pressure water

- Maintenance

- Easy

- Retrofit Ability

- Easy to retrofit

- Belt Lifetime Improvement

- Improved due to optimal cleaning

- Cleaning method

- Optimal rotating design

- Water usage

- Minimal high-pressure water

- Dryness consistency

- Stable over entire belt width

- Maintenance ease

- Easy with standard parts

- Retrofitting capability

- Easy to retrofit

- Belt lifetime

- Improved due to optimal cleaning

- Cleanability

- Easy maintenance with standard spare or wear parts

- Abrasion resistance

- Improved belt lifetime thanks to optimal cleaning

- Corrosive resistance (e.g. acids)

- Stable product dryness over the whole belt width

- Control panel type

- Standard

- Integration possibilities

- Easy to retrofit