Making Kaolin

Find innovative production technology for making kaolin and connect directly with world-leading specialists

Kaolin, also called china clay, is made from natural rock composed of aluminosilicate clay or kaolinite. Kaolin has wide applications in different industries. Moreover, their classification depends on their industrial use, which includes film formation, fiber extension, polymer extension and chemical composition. Choose a kaolin processing machine to help you make kaolin for beauty products, paper filler, coating, ceramics and even medicine.

Select your kaolin process

Tell us about your production challenge

Removing impurities with the help of a kaolin processing machine

Extracted kaolin has many impurities. It’s essential to purify the resulting clay slurry through bleaching before grinding it to improve the particle size to a fine soft texture. To achieve this separation, use the flotation technique. It removes the colored impurities and gives you the white kaolin by calcination. Note, also, that fine particle size is a problem in flotation. This is why it is advisable to use methods of flotation based on the range of fine particles and industry. It is important to remove excess water by drying to have control of the product’s end moisture. You can use a fluid bed dryer to achieve this.

A valued mineral: kaolin application in different industries

Kaolin has unique chemical and physical properties which makes it a valued natural mineral in the manufacturing industry. The paper industry mixes kaolin with cellulose fiber for filling, and mixes it with water and adhesives for coating. This is to increase printability. Health benefits of kaolin make it a sought after mineral in the medical and pharma industry.

It can treat diarrhea, mouth sore, ulcers, and also helps in tablets production. Controlling the level of viscosity is a problem in the adhesive industry, but including kaolin during production with an enclosed mixing system for adhesives can help you with that. Kaolin processing equipment helps grind kaolin to a suitable particle size. This controls low and high shear viscosities of adhesives.

Wide range of applications requires different processing methods

Kaolin products are widely used in cosmetology because of their fine size particles, which makes them safe and smooth on skin. For this reason, they can compose exfoliant, anti-inflammatory and anti-bacterial products. The absorbent nature of kaolin makes it a good oil control product.

Kaolin helps to detoxify the scalp and prevents yeast growth. Kaolin clay can also be a deodorant alternative because of its ability to neutralise body odor. For a clearer plague-free dentition, kaolin can also be included in tooth powder. The method of processing depends on the industry. For example, the paper industry uses the wet process while ceramic manufacturers use the dry-processed kaolin. Mechanical methods using kaolin processing machine for crushing and screening don’t alter their chemical properties.

How to decrease kaolin’s environmental impact

Kaolin has little or no adverse effect on human health. Yet, the open pit mining of kaolin clay creates environmental disturbance and water erosion. To reduce erosion, there are regulatory laws that require levelling the mined area. This involves planting of trees and dust control while operating a kaolin making machine. By doing that, studies have shown that kaolin is environmentally safe. Producer’s main concern should be the mining process, which may lead to release of toxic chemicals into underground water. However, operating companies have found safer ways, such as creating a number of independent pits for mining activities.

Processing steps involved in kaolin making

Which kaolin technology do you need?

Laboratory drum mill for large sample volumes

Efficiently process large volumes of diverse materials into precise particle...

Planetary ball mill for high throughput grinding

For precise material engineering, achieve efficient size reduction, homog...

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for co...

High shear impact mixer for agglomeration and dispersion

Achieve precise homogeneity and efficient agglomeration with a h...

Continuous mixing for fine and cohesive powders

Achieve unparalleled mixing precision for cohesive powders while reducing ...

Powder mixing systems

Optimize your production line with precision powder mixing systems that ensure uniformity, enhance prod...

Choppers and disintegrators for industrial size reduction

Enhance your production efficiency by mastering size reduction...

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Drying systems for powders and bulk solids

Enhance your production line with precise control of moisture content in powder...

Lab mixer for high-accuracy powder and paste mixing

Achieve precise mixing of powders and pastes with a gentle convective...

Powder characteristic evaluation

Ensure precise powder analysis and testing in your laboratory to optimize production qualit...

Cip/sip cleaning for solids processing systems

Ensure seamless transitions and maintain hygienic production environments w...

Containment solutions for hazardous material processing

Ensure safe and efficient processing of hazardous materials with ...

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Ultra-fine powder flash drying system

Achieve rapid moisture removal and particle refinement with this integrated system, d...

Ultrafine classifier for precise particle separation

Gain precise control over particle size with this ultrafine classifi...

Ultrafine classifier for soft to medium-hard mineral processing

Achieve exceptional particle precision with an ultrafine...

Industrial evaporators for diverse applications

Maximize energy efficiency and reduce operational costs with cutting-edge ...

2-phase separating decanter for chemical and mineral processing

Ensure precise separation and optimal moisture control i...

Flash dryer for corn starch

Reduce energy consumption and maintain product quality with efficient drying solutions designed ...

High precision color sorting system for minerals

Achieve unparalleled sorting precision with advanced color recognition te...

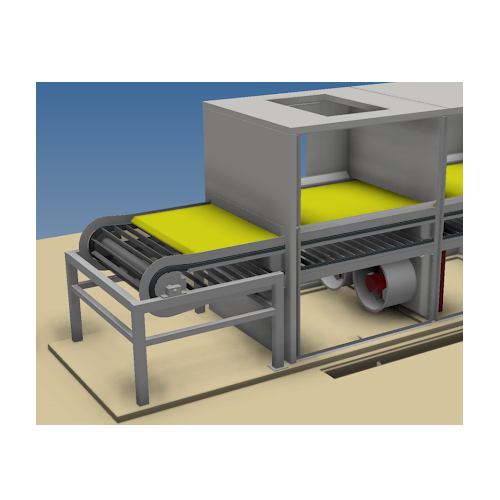

Belt dryer for large-scale continuous drying

Achieve precise moisture control and energy-efficient processing with this be...

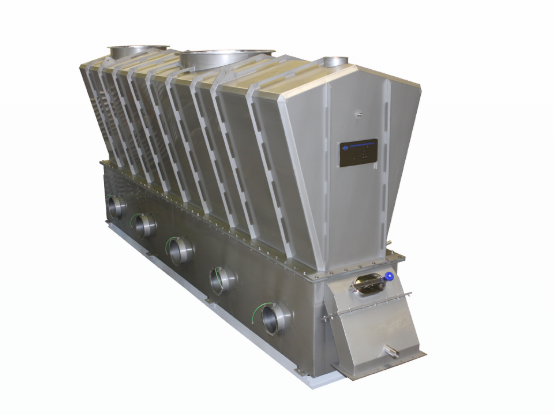

Continuous bulk fluid bed dryer

Achieve rapid and energy-efficient moisture removal across diverse materials with our advanc...

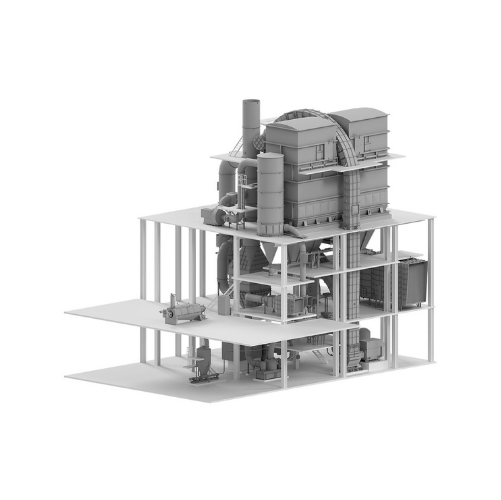

Efficient grinding and drying mill

Transform your production line with a versatile mill that simultaneously grinds, dries, ...

Industrial high-speed turbo blender

Achieve homogeneous blending with high-speed precision, ideal for creating fine product...

Pneumatic drying system for industrial slurries

Efficiently transform high-moisture slurries into dry solids in a single p...

Vertical ring-roll mill for pulverizing minerals

Achieve precise particle size control and efficient material processing w...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

Horizontal rotary ball mill drum

A horizontal rotary ball mill drum can be used for grinding of dry hard materials, such as ...

Big bag discharge system

Dust emissions, product loss and product contamination are the main risks when discharging products ...

Light duty rotary dust valve

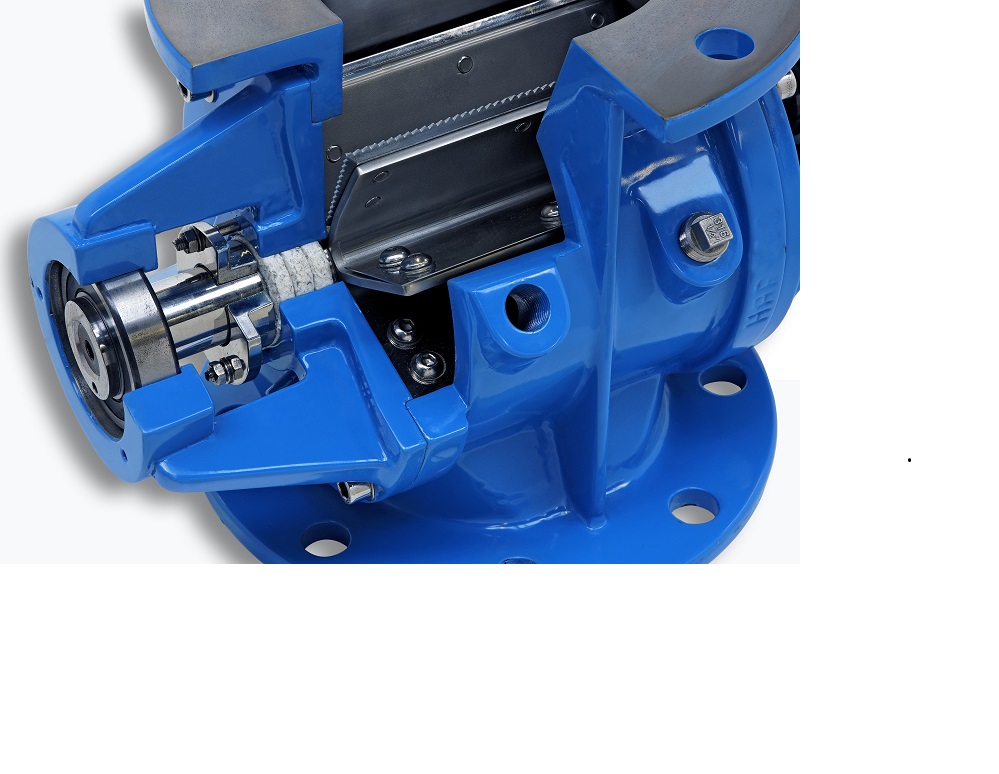

In some light industrial applications there is limited pressure differential for valve operation.

Heavy duty rotary valve

Handling powdered and granulated materials in pneumatic conveying systems requires consistent, safe v...

Special duty horizontal metering valve

Occasionally, there is no suitable standard valve available for a particular conveyi...

Dual channel plug diverter valve

Short switching times are often required when diverting or combining powder or granular sol...

Two-way flap type diverter valve

Routing powder, pellets or granules from a product source to two receiving points must be d...

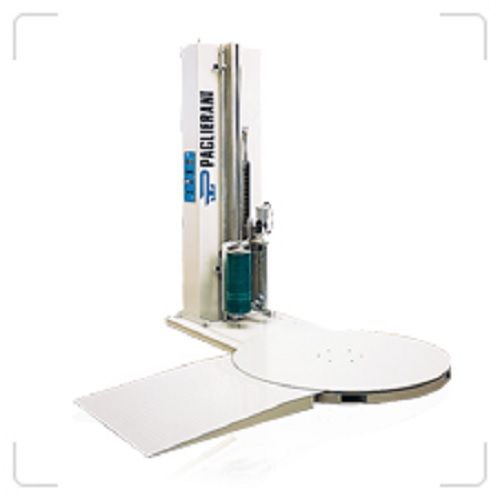

Semi-automatic stretch wrapping machine

At lower speeds, some level of automation is required to provide a cost-effective m...

Traditional palletizer for bags

Packaging lines may require a single, flexible solution that can handle many different palle...

High-capacity bulk weighers

A checking weigher recognized for receiving and shipping bulk materials, typically in mills and ...

Hygienic open-mouth bottom-up baggers

Here are the open-mouth baggers that are specially designed for hygienic bagging of p...

Open-mouth bottom-up baggers

Innovative bottom-up baggers for high-speed industrial packaging will help you create a dust-fr...

Circuit-air classifier

For high throughputs, with a fineness range of approx. d97 = 32 µm – 200 µm. Ideal for use in th...

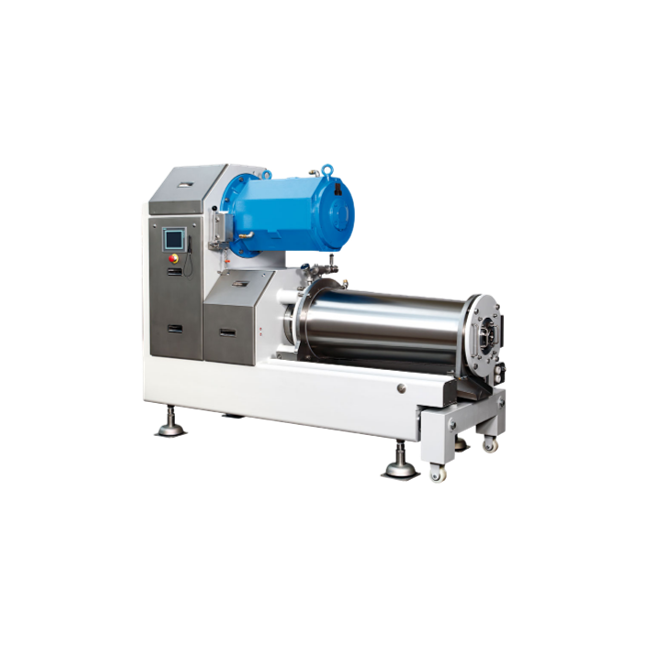

Vertical agitated dry media mill

A vertical agitated media mill is used for grinding ultrafine particles, in an agitated (or...

Pelleting press with overhead drive

Production of certain pelletized products requires working with output products of a pa...

Small scale pelleting press

Many industries require reliable pelletizing equipment with smaller scale production capacities....