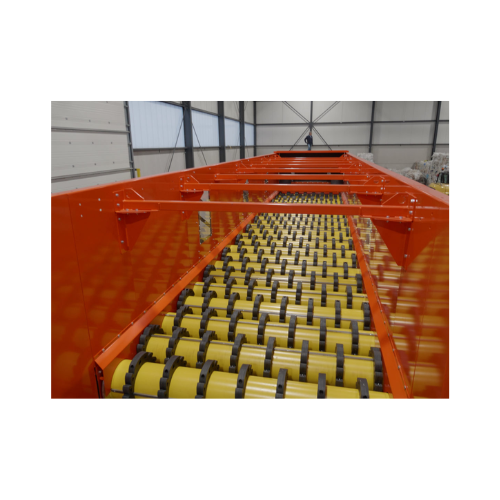

Anti-wrapping starscreen for material sorting

Tackle film, tape, and textile wrapping issues in your sorting process with this starscreen technology designed for precise size separation and minimal maintenance.

Separates and Screens Waste for Recycling Operations

The Lubo AWS Starscreen from Bollegraaf Group is engineered to address the common problem of material wrapping in waste processing, enhancing separation efficiency. Its patented anti-wrapping design ensures uninterrupted operation by preventing obstructions from films, tapes, and textiles. Applying this technology, AWS optimizes sorting for various waste streams, producing high-purity outputs such as recycled PET flakes, reprocessed cardboard sheets, and RDF pellets.

The AWS Starscreen employs a unique modular construction, screening materials in a thin layer for superior separation. With a high throughput capacity, it efficiently processes materials like municipal solid waste, construction debris, and plastic, supporting single stream and waste-to-energy solutions.

Highlighting its operational advantages, AWS integrates high automation with minimal energy consumption, facilitated by a PLC-controlled system. Maintenance is streamlined with the Quick Disconnect System, enabling rapid star shaft replacements without extended downtime, thereby maximizing uptime and lowering operational costs. Compatible with existing installations, the Lubo AWS Starscreen is tailored to meet the advanced needs of recycling facilities and waste management companies.

Benefits

- Enhances material purity with effective separation, reducing contamination in recyclable outputs.

- Minimizes operational costs and increases uptime with low-maintenance, easy-change shaft design.

- Conserves energy with optimized motor controls, lowering overall power usage.

- Adapts easily to existing systems due to its modular design, enabling flexible integration.

- Improves sorting efficiency by preventing material wrapping, ensuring consistent throughput.

- Applications

- Paper and cardboard waste, Construction and demolition (c, Single stream waste, Plastic waste, Municipal solid waste (msw), Waste-to-energy solutions, D) waste

- End products

- Recycled pet flakes, Recovered corrugated fiberboard, Refined mixed recyclables, Recycled construction aggregates, Cleaned municipal recyclables, Rdf pellets, Reprocessed cardboard sheets

- Steps before

- Feeding, Material Sorting, Initial Screening

- Steps after

- Density Separation, Ballistic Separation, Sorting Overs, Process Automation

- Input ingredients

- film, tape, textile, plastic bags, foils

- Output ingredients

- purity, quality, recovered valuables, sorted material

- Market info

- Bollegraaf is known for manufacturing advanced recycling equipment and systems. With a strong reputation for innovation and quality, they specialize in engineered-to-order solutions, optimizing waste processing efficiency and sustainability for diverse industries globally.

- Modularity

- High

- Ease of Maintenance

- Quick Disconnect System

- Automation Level

- High

- Operational Costs

- Low

- Energy Consumption

- Low

- Throughput

- High

- Purity

- High

- Uptime

- Maximized

- Anti-Wrapping Feature

- Yes

- Material Layer Thickness

- Thin

- Flexibility to Amend Settings

- High

- Construction

- Modular

- Maintenance Time

- Minutes

- Shaft Change Speed

- Fast

- Setting Amendability

- Flexible

- Modularity

- Modular construction

- Automation level

- High level of automation

- Ease of maintenance

- Quick Disconnect System

- Purity and quality

- Highest purity and quality

- Changeover time

- Minutes with Quick Disconnect

- Operational costs

- Low operational costs

- Throughput

- High throughput

- Flexibility

- Amend settings easily

- Anti-wrapping feature

- Prevents obstruction

- Energy consumption

- Low energy consumption

- Uptime

- High uptime

- Film compatibility

- Yes

- Tape resistance

- Yes

- Textile handling

- Yes

- Cleanability

- Easy maintenance

- Waste Streams Compatibility

- All Types

- CE marking

- Yes

- ISO 9001 Certification

- Yes

- ATEX Certification

- Yes

- Machine Footprint

- Compact

- Screen Design

- Anti-Wrapping

- Modularity

- Yes

- Shaft System

- Quick Disconnect

- Control panel type

- High level of automation

- Maintenance customization

- Quick Disconnect System for easy shaft change

- Integration possibilities

- Flexible settings to integrate with existing systems

- Modular construction

- Can be built in almost every existing situation