Multi-channel blending silo for free-flowing bulk materials

Achieve precise homogenization and mixing of free-flowing bulk materials with a seamless integration into existing processing lines, ensuring consistent product quality and efficient operation.

Achieves Precise Blending and Homogenization

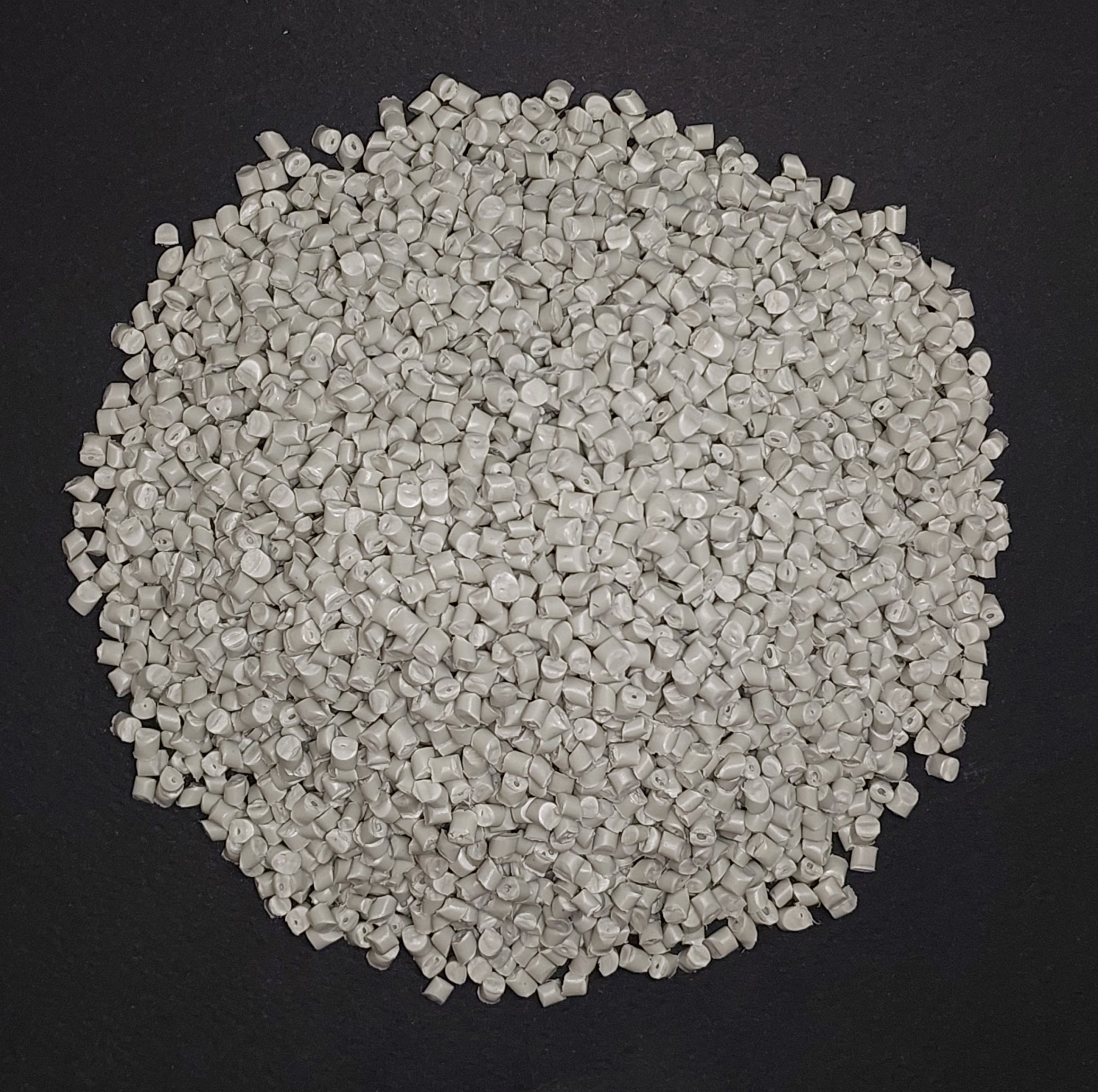

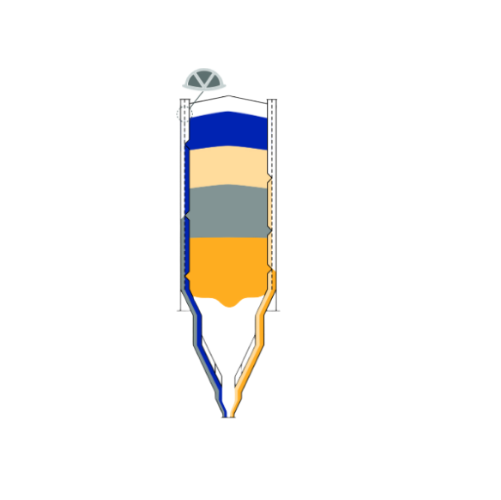

The Multi-Channel Blending Silo ZSD from Zeppelin Systems offers advanced integration into your production line, ensuring precise homogenization of free-flowing bulk materials like polyethylene pellets and cocoa powder blends. Using vertical blending pipes, it collects materials from 18 different heights, directing them to a central blending chamber for consistent mixing. Ideally suited for the plastics, rubber, and food industries, the silo supports both continuous and batch operations, accommodating variable fill levels down to 25%.

With a design focused on optimizing mass flow, it guarantees reproducible results for mixing and degassing applications. The blending pipes are welded directly to the silo shell, eliminating the need for additional fixings and allowing for residue-free emptying, which simplifies cleaning and maintenance processes. Tailored for automated systems, the Multi-Channel Blending Silo ZSD ensures seamless operation with your existing process controls, offering efficiency and reliability in the handling of solid and granule product types.

Benefits

- Ensures uniform product quality through consistent batch homogenization.

- Reduces downtime with easy integration into existing processing lines.

- Minimizes material waste with residue-free emptying.

- Adapts to variable production demands by operating efficiently at different fill levels.

- Enhances process accuracy by supporting optional degassing functions.

- Applications

- Pellets, Food industry, Plastics, Rubber and tire industry, Free-flowing bulk materials

- End products

- Polyethylene pellets, Rubber compounds, Polypropylene granules, Tire treads, Cereal grains, Flour mixtures, Cocoa powder blends

- Steps before

- Material Delivery, Material Feeding, Storage, Pre-Blending

- Steps after

- Blending, Material Discharge, Post-Processing, Packaging

- Input ingredients

- free-flowing bulk materials, pellets

- Output ingredients

- homogenized batch, mixture from the entire silo

- Market info

- Zeppelin Systems excels in designing and manufacturing high-quality bulk material handling and processing equipment. Renowned for its engineering expertise, the company serves industries including plastics, chemicals, and food, ensuring efficient, reliable, and innovative solutions tailored to customer needs.

- Blending pipe count

- 6 blending pipes

- Chamber per pipe

- 3 chambers

- Batch operation

- Batch homogenization

- Fill level requirement

- Down to 25%

- Emptying method

- Residue-free emptying

- Automation

- Process Control

- Integration

- Easy integration into processing

- Batch homogenization

- Yes

- Continuous and non-continuous mixing

- Both

- Fill level adaptability

- Down to approximately 25%

- Residue-free emptying

- Yes

- Degassing compatibility

- Yes

- Single-cycle efficiency

- Sufficient for many applications

- Abrasion resistance

- Yes

- Biological compatibility

- No

- Cleanability

- Yes

- Density/particle size

- 0.5–2.5 g/cm³

- Corrosive resistance (e.g. acids)

- No

- Tank shape

- Vertical cylindrical

- Number of blending pipes

- 6 blending pipes

- Number of chambers per blending pipe

- 3 chambers

- Discharge method

- Central outlet cone

- Compact footprint

- Easy integration

- Fill level usage

- Approximately 25% to full

- Residue-free emptying

- Yes

- Pipeline Installation

- Welded to silo shell

- Control panel type

- PLC / SCADA / HMI

- Integration possibilities

- Easy integration into processing

- Design flexibility

- Used at different fill levels