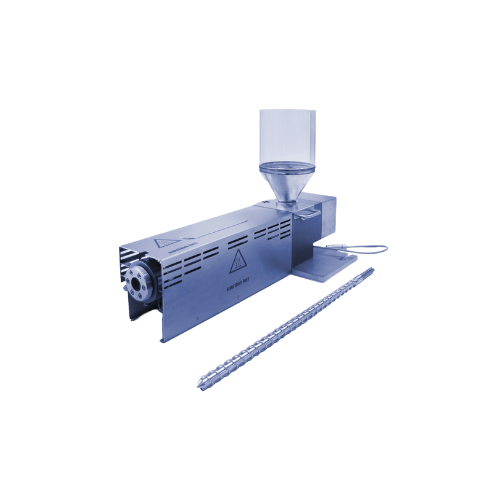

Polymer testing extruder

Effortlessly evaluate polymer and plastic product properties with precision, ensuring your materials meet the highest performance standards in research and development environments.

Processes and Transports Polymers and Plastics

The Brabender Extruder / Extrusiograph Models 19/25 and 19/32 are versatile extruders designed to investigate the extrudability of polymers and similar products. These instruments excel in melting, homogenizing, and transporting materials with precision. The unique modular measuring head accommodates small sample volumes, making it ideal for research and development as well as material testing facilities. Common applications include producing polyethylene films, polypropylene pipes, and rubber gaskets, while the equipment effectively manages processes like extrusion, melting, and homogenization. Offering seamless integration into both continuous and laboratory operations, these extruders support precise measurement and evaluation. With various die head and conveyor options, users can configure the extruder to fit specific needs, ensuring high-quality output in plastics, polymers, and food industries.

Benefits

- Enhances production efficiency by precisely controlling extrusion processes.

- Adapts to diverse applications with customizable die head options.

- Minimizes material waste with accurate sample volume measurement.

- Facilitates R&D innovation with user-friendly integration into lab environments.

- Supports sustainable practices with energy-efficient operation.

- Applications

- Polymers, Plastic products, Pasta, Feed products, Film products, Food products, Wire coatings, Rubber

- End products

- Biodegradable garbage bags, Spaghetti, Animal feed pellets, Rubber gaskets, Polypropylene pipes, Coaxial cables, Instant noodles, Polyethylene films

- Steps before

- Material Preparation, Pre-heating, Mixing, Compounding

- Steps after

- Cooling, Cutting, Pelletizing, Quality Inspection

- Input ingredients

- polymers, flowable products

- Output ingredients

- extrudates, films, strands, pasta, pellets

- Market info

- Brabender is renowned for producing high-quality, engineered-to-order lab equipment for material testing, particularly in food and plastics industries, specializing in precision instruments for measuring, preparation, and processing.

- Extruder Type

- Single Screw

- Sample Volume

- Small

- Measurement Points

- 3

- Cylinder Type

- Grooved

- Screw Diameter

- 19 mm

- Barrel Diameter

- 19/25 and 19/32 mm

- Sample volume

- Small

- Cylinder type

- Grooved

- Measurement points

- 3

- Automation level

- Manual / Automated Data Transfer

- Extrusion Process

- Batch / Continuous

- Polymer compatibility

- Yes

- Flowability

- Flowable products

- Thermal stability

- Melted in the heated extruder

- Measuring points

- 3

- Discharge method

- Die onto discharge side

- Modular measuring head

- Yes

- Sample volume adaptability

- Small samples

- Grooved cylinder option

- Available

- Number of measuring points

- 3

- Die configurability

- Optional modules