Bioplastic Manufacturing Machines

Find innovative production technology for making bioplastics and connect directly with world-leading specialists

Plastic pollution is one of the biggest climate-related problems mankind has. So what are your options? A bioplastic machine can help create an alternative to traditional plastics. Bioplastics, differently from regular plastics, don’t cause environmental contamination. Also, they don’t contain harmful ingredients and additives. Even with these benefits, the annual production of bioplastics is still less than one percent of all plastic making. However, the market is witnessing steady growth due to a rise in demand.

Technology picks for bioplastics

Agitated nutsche filter dryer for solid-liquid separation

Achieve high-purity solid-liquid separation with optimized thr...

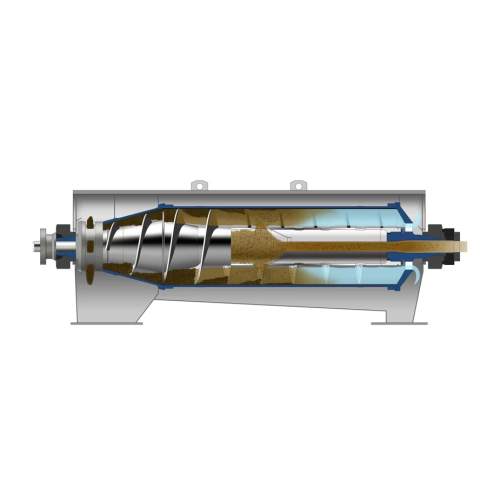

3 phase decanter centrifuge for industrial separation

Optimize your production line with efficient three-phase separation...

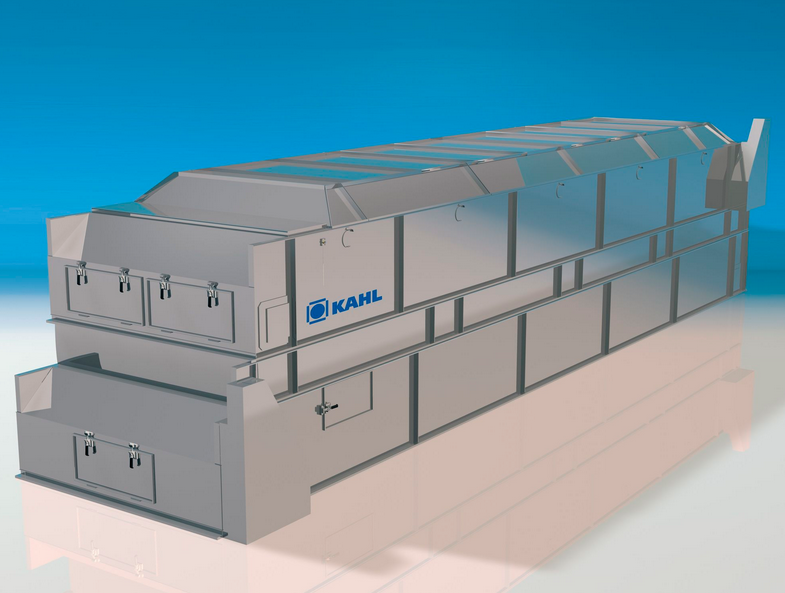

Belt dryer/cooler for pellets and granules

Many industries that process materials in pellet, powder, or crumble form need ...

Automated polymer melt flow rate measurement system

Achieve precise polymer quality control by continuously analyzing mel...

Tell us about your production challenge

Production challenge: compounding bioplastics in a bioplastic machine

Bioplastic processing can be quite challenging, especially at the compounding stage. The wide range of available base polymers and differences in formulation makes it difficult to design a material handling and feeding system. For the final product to meet the required standard, you must set every process in the bioplastic machine to precision to avoid production loss.

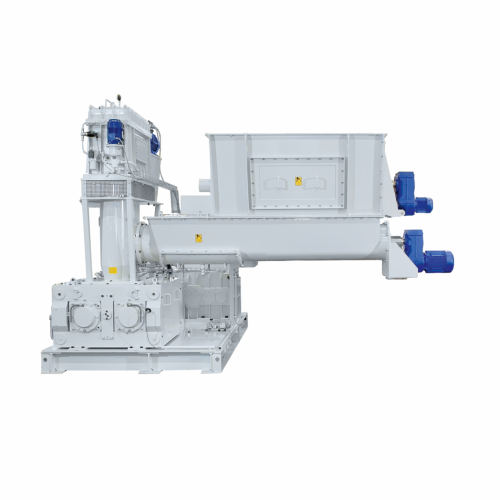

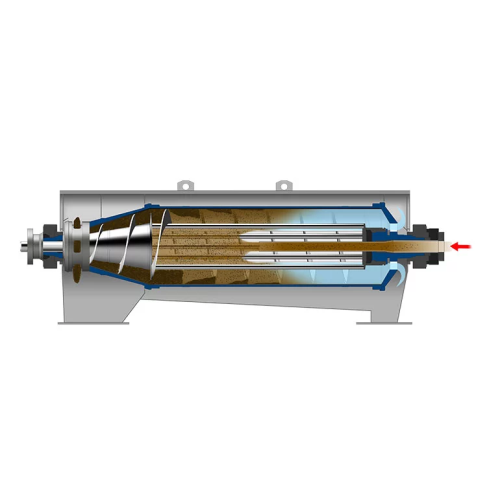

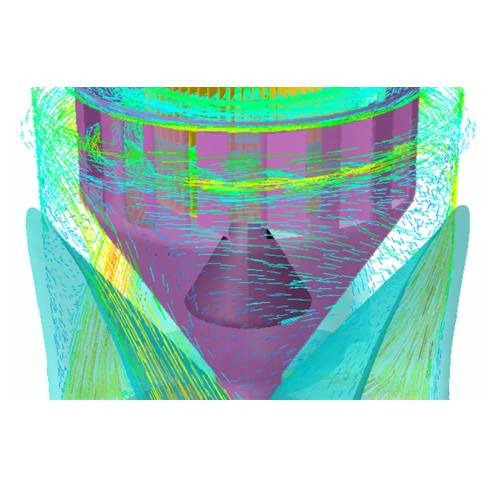

However, technological developments in the compounding process make the process less challenging. One of them focuses on easily processing bioplastic polymer compounds through twin-screw extrusion. They increase the mixing efficacy of different components, providing a homogeneous result.

Is bioplastic completely better than plastics?

Bioplastics are indeed eco-friendly. They reduce fossil fuel usage and lower the release of toxic emissions. Moreover, their production significantly lowers the amount of non-biodegradable waste that pollutes the environment such as plastic shopping bags. In addition, they have a higher permeability to water vapor and do not change the taste of the food they contain. Bioplastic bag making machines also make softer and more tactile bags for cosmetics packaging.

However, the properties of some bioplastics, such as thermal instability, difficult heat saleability, brittleness, low melt strength, limit their use as a film in food packaging applications.

Another downside and worry in the production of bioplastics is their impact on agriculture and biodiversity. It competes with food production for agricultural resources and raw materials such as corn starch or sugar cane and utilizes a large portion of agricultural land.

The current trend in bioplastic manufacturing

Bioplastic is only likely to grow at an average of 3% relative to 3.5%-4% for polyethylene, polypropylene, and other plastics. The major factor contributing to this is the high cost of production. They cost twice or three times as much as conventional plastics. Another factor is the high competition for agricultural materials. In addition, some bioplastics have a shorter lifetime than traditional oil-based plastics due to their brittleness poor mechanical and barrier capabilities.

However, carbon emission taxation and single-use, fossil-based plastic bans already implemented in European countries such as France and Belgium may help boost the bioplastic industry by reducing the production of traditional plastics.

Lifespan of bioplastics

The longevity of a bioplastic depends on its end uses. For instance, for foods with a shelf-life of less than six months, opt for bioplastics with high biodegradability, including starch and cellulose. For foods with about five years shelf life, use options such as Polylactic acid (PLA). It takes a long time to biodegrade and undergo recycling. However, it is not advisable to store water-sensitive products in PLA for a prolonged period. Regardless of duration, bioplastics can be disposed along with other organic household waste. Microorganisms break them down into carbon dioxide, water, and biomass at the same rate as other organic materials.

Processing steps involved in bioplastics making

Which bioplastics technology do you need?

Compact fermentor for research and scale-up studies

Optimize your bioprocess development with a desktop fermentor that of...

Small scale fermentor/bioreactor for multi-condition bioprocessing

Explore diverse fermentation conditions with precisi...

High-pressure roller compactors for chemical, food, and minerals industries

Achieve precise particle compaction and br...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Biomass baler for woody biomass collection

Optimize woody biomass management with a mobile solution that reduces noise, du...

2-phase separator for clarifying liquids

Efficiently refine and clarify liquids while minimizing waste. This 2-phase separa...

3-phase liquid separation solution

Achieve precise separation of liquids and solids to enhance product quality and streamli...

3 phase decanter centrifuge for industrial separation

Optimize your production line with efficient three-phase separation...

Decanter centrifuge for wastewater treatment

Effectively manage waste streams and enhance resource recovery with this high...

Advanced sludge dewatering for sewage treatment plants

Optimize sludge dewatering with a centrifuge that enhances separat...

High-performance decanter centrifuge for industrial separation

Optimize your production with a centrifuge solution that ...

Industrial nozzle separator for high solids concentration

Optimize your production with high-performance nozzle separato...

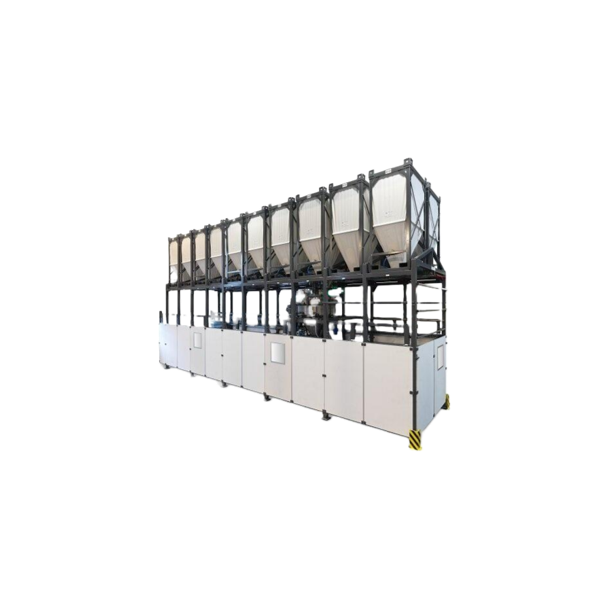

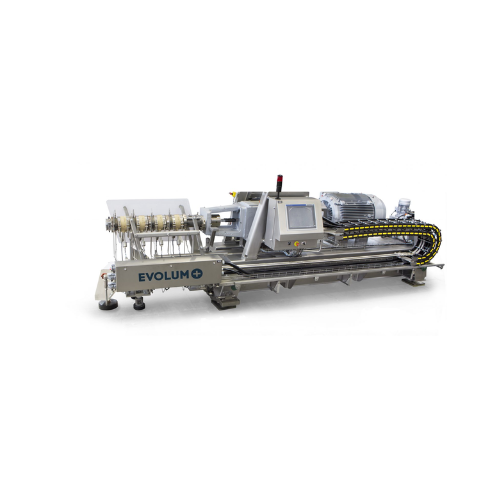

Precision feeders and mixers for plastics processing

Achieve precise blending and feeding for plastics processing with mo...

Gravimetric batch blender for plastics compounding

Achieve precise batch blending with high accuracy, ensuring consistenc...

Industrial strand pelletizer for polymer processing

Optimize polymer pellet production with precision engineering, ensuri...

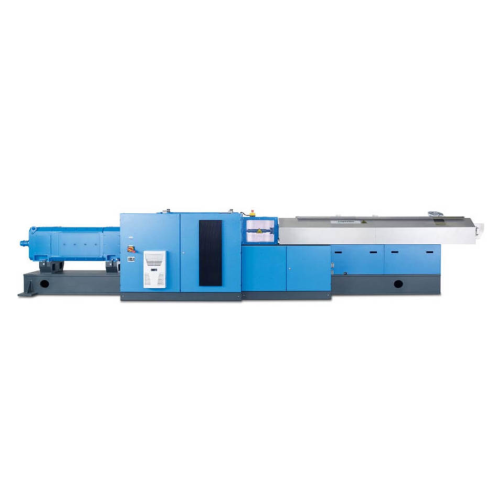

High throughput twin screw extruder for low bulk density products

When handling low bulk density materials, achieving m...

High-performance twin-screw extruder for food production

Enhance your production line efficiency and product quality with...

Cross flow filtration for industrial liquid purification

Optimize your production process with advanced cross flow filtra...

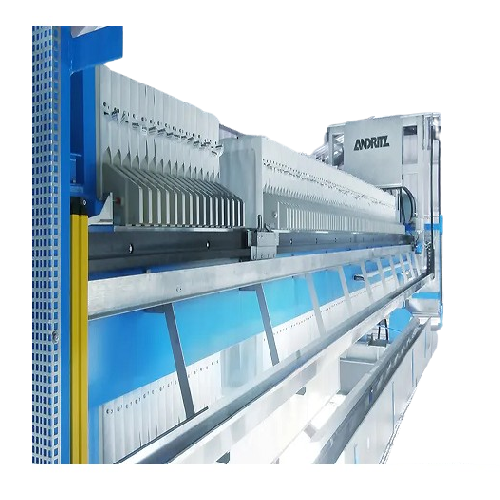

Industrial filter press for dewatering and filtration

Optimize your dewatering and filtration needs with a highly adaptab...

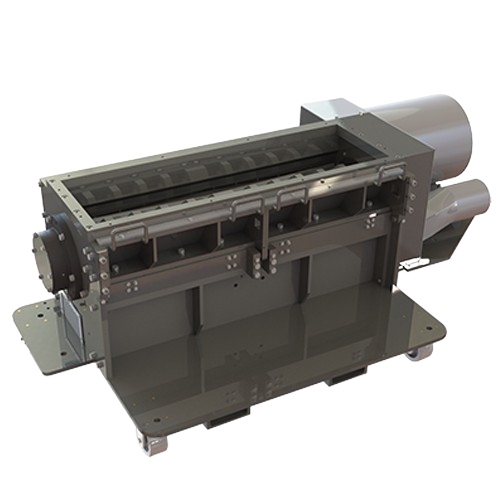

Beside-the-press granulators for injection molding

Optimize your plastic production by efficiently reclaiming resin with ...

Central granulators for high-volume plastics recycling

Efficiently process large volumes of recycled plastics and industr...

Heavy duty granulator for high-capacity size reduction

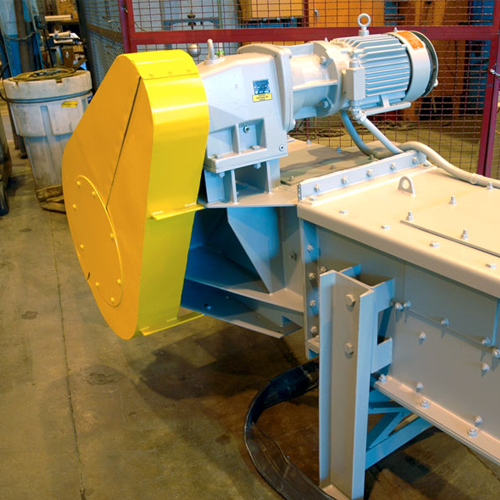

When tackling high-volume materials, rely on these industrial-grad...

Thermoforming granulators for efficient material processing

Efficiently recycle and optimize your plastic waste by trans...

3.5 Hp air-cooled chiller for industrial cooling

Optimize your production with high-efficiency cooling, essential for main...

Positive/negative pressure temperature control unit for cooling circuits

Ensure precise temperature regulation and prev...

Central chiller for consistent process cooling

Optimize your production with modular central chillers offering scalable co...

Compact water temperature control unit

Achieve precise temperature control in cramped production spaces, enabling consisten...

Water temperature control unit for production applications

Enhance your production efficiency by precisely managing wate...

Stainless steel drying hoppers for plastic processing

Optimize moisture control for thermoplastics with robust drying hop...

Digital doser system for plastics additive feeding

Achieve precise additive dosing for plastics, ensuring consistent qual...

Extrusion control units for high precision manufacturing

Optimize your extrusion process with precision control over thro...

50l jacketed glass reactor for synthetic reactions

Achieve precise control over chemical reactions and material synthesis...

10l glass reactor system for synthetic reactions

Achieve consistent reaction control with efficient temperature and vacuum...

150l jacketed glass reactor for chemical synthesis

Achieve precise control over complex chemical processes with this sing...

Industrial distillation testing services

Ensure optimal purity and performance by utilizing advanced pilot and mobile disti...

Ammonia chiller for industrial refrigeration

Achieve optimal energy efficiency and reduced operational costs in your cooli...

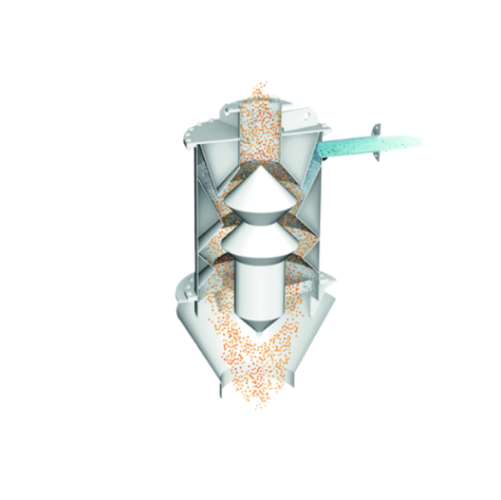

Air separator for polymers and plastics

Ensure high-purity plastic pellets by efficiently separating fine dust and streamer...

Atex certified flanged round dust collectors

Designed for potentially explosive environments, these flanged round dust col...

Horizontal screw press separator for pomace yield optimization

Enhance your production line by efficiently separating so...

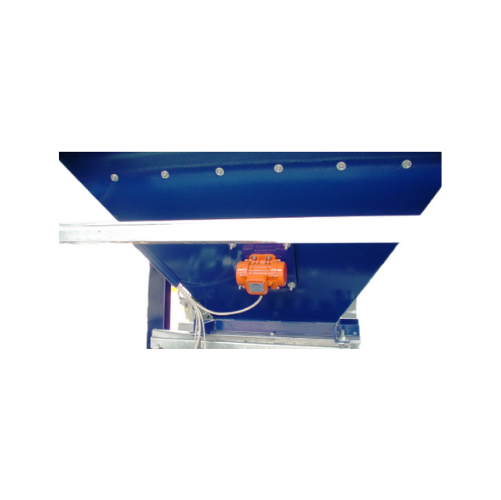

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

High efficiency micro-batch feeder for powdery or granular materials

Achieve precise volumetric feeding and metering of...

Granulate screening technology for precise particle size separation

Achieve exceptional sorting precision and maintain ...

Autoclavable fermenters for small scale bioprocessing

Optimize your bioprocesses with configurable fermenters offering pr...

Customizable pilot-industrial fermenters bioreactors

Designed for precision fermentation, these fermenters and bioreactor...

Scale hopper for bulk solid material handling

Ensure precise measurement and efficient transport of bulk solid materials w...

Crane weighing system for precision measurement

Ensure precise and temperature-resistant weighing during high-demand opera...

Mass flow rate feeder for bulk powders

Achieve precise control and consistent material flow in high-speed manufacturing env...

Solid flow meter for granular and powdered bulk materials

Ensure accurate mass flow measurement and seamless integration...

Solid flow meter for continuous bulk material measurement

Ensure consistent and accurate measurement of bulk solid mater...

Bin weighing system kits for precise weight control

Ensure accurate material measurement in challenging environments with...

Industrial air classifiers for pulverized fuel production

Optimize your fuel production process with precision disc turb...

Industrial grinding mill replacement parts service

Optimize production efficiency with high-precision grinding solutions ...

Ultrafine powder mill for coatings and pigments

Optimize your ultra-fine powder production with this precise grinding and ...

Solids flow meter for bulk solid streams

Ensure precise bulk material measurement with a system designed for accuracy and r...

Loss-in-weight feeder for bulk solids

Ensure precise and reliable dosing of bulk solids with a compact feeder that eliminat...

Apron weighfeeder for sticky bulk materials

Optimally handle challenging, sticky materials with precision and consistency ...

Industrial weighfeeder for hygienic applications

Achieve precise mass flow control with a hygienic design, ideal for appli...

Continuous and batch feeding system for bulk materials

Achieve precise bulk material feeding with seamless integration in...

Optimal maintenance solution for industrial weighfeeders

Streamline your processing operations with a solution that minim...

Multipurpose feed station for bulk solids

Optimize your production line with a versatile feeding station designed for simu...

Dense phase pneumatic conveying accessories

Optimize material flow and reduce power consumption with dense phase pneumatic...

Drop forged chain for drag chain conveyors

Enhance your material flow efficiency with a robust drop forged chain designed ...

En-masse chain conveyor for bulk material handling

Streamline your bulk material handling with a gentle, efficient system...

Bulk material handling with chain conveyor

Optimize your material transport with a solution designed for reliability in de...

Tube belt conveyor for long-distance material handling

Ensure seamless and protective transport of bulk materials across ...

Self-cleaning candle filtration system

Separating solids from liquids by filtration requires frequent cleaning or replaceme...

Open mouth bagging machine

If you are a manufacturer of fertilizers, bulk chemicals, sugar, seeds, or any grains it is likel...

Open mouth bag filling machine for powders

The packaging of powdery products such as flour can be challenging as it is cru...

Form fill seal bagging machine

If you are in industries such as petrochemicals, fertilizers, animal feed, food, etc, you mus...

Vertical form fill seal machine

There is an increasing demand for a range of different package sizes of the same product. If...

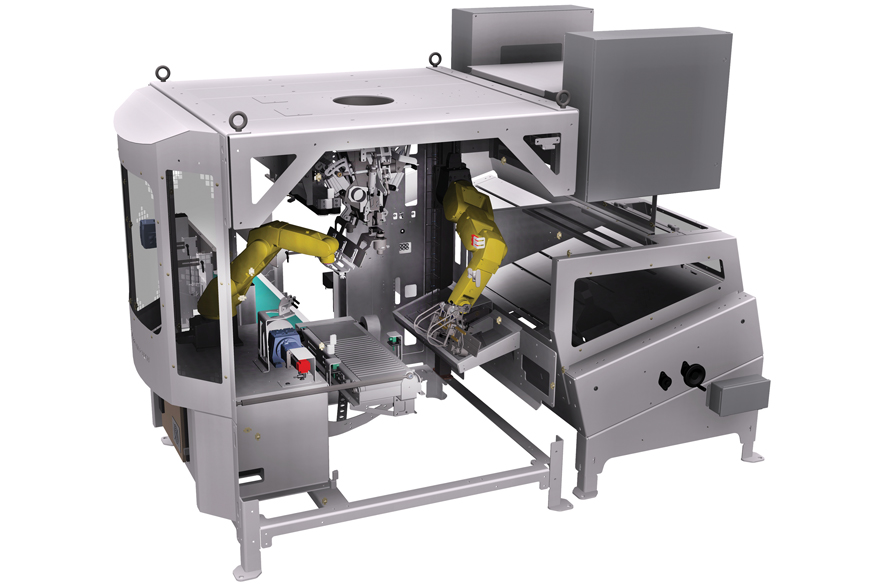

Robot palletizing system

If you are a relatively large-scale producer, packing and transporting large quantities of products ...

Automatic bag slitter

Unacceptably high dust levels can be generated whilst manual emptying and handling of bags, also produc...

Pelleting press for biomass

Utilization of biomass for energy and other applications requires consistent and reliable compac...

Big bag solutions

Management of big bags requires specialist handling and selection of cost-effective configurations for fill...

Hygienic FIBC handling line

There are many considerations when handling FIBC’s (Flexible Intermediate Bulk Containers)...

Big bag discharge system

Dust emissions, product loss and product contamination are the main risks when discharging products ...

Light duty rotary dust valve

In some light industrial applications there is limited pressure differential for valve operation.

Special duty horizontal metering valve

Occasionally, there is no suitable standard valve available for a particular conveyi...

Tumble dryer for granulated plastics

Vacuum drying at high temperatures is important in the production of granulated plasti...

In-process weighing system for mills

When you need a throughput weigher for modern flour/grain milling applications, the we...

Deduster for plastic granules

Industries that use plastic granules see better product quality and decreased equipment wear a...

High-level layer palletizer

A palletizer that meets the middle and high-level needs of modern bagging lines. Quite suitable ...

Versatile open-mouth bagger

If you want highly precise bagger for bagging multiple bag materials, here you go. This versatil...

Hygienic open-mouth bottom-up baggers

Here are the open-mouth baggers that are specially designed for hygienic bagging of p...

Pipe bend to reduce fines

A specialized pipe elbow for pneumatic conveying systems that virtually eliminates the friction an...

Laboratory granule dedusting analyzer

High quality clean bulk materials are used in many industries including plastics, foo...

Small scale deduster for plastic granules

Industries that use bulk plastics see better product quality and decreased equip...

Deduster for injection moulding

High quality injection molded plastic parts require clean bulk resins free of dust and strea...