Industrial air classifiers for pulverized fuel production

Optimize your fuel production process with precision disc turbine technology, designed to improve particle classification and ensure consistent fuel quality essential for high-efficiency combustion systems.

Enhances Particle Classification and Fuel Pulverizing

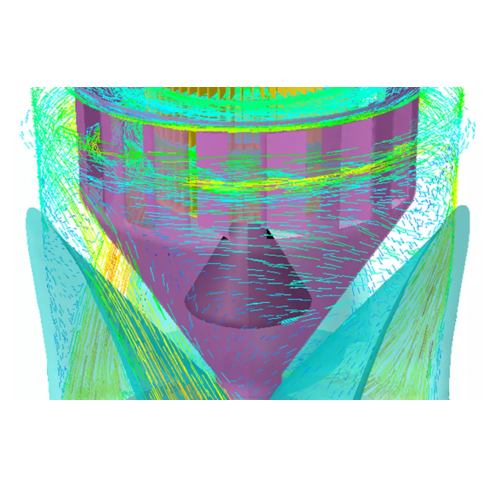

The Raymond® Turbine Classifier from Raymond® Classifiers is engineered for precision in coal and solid fuel processing. Specially designed with a hybrid turbine technology, this classifier improves particle size distribution and maximizes efficiency in pulverizing systems. It seamlessly integrates with roller and bowl mills, optimizing operational performance across industries like steelmaking and cement. Capable of handling diverse materials from anthracite to NPK fertilizer blends, it achieves consistent fineness with dynamic control. The robust construction ensures longevity in demanding environments while offering flexibility in system integration, making it ideal for continuous and high-speed operations. Simplified maintenance is supported by a globally recognized support network, ensuring minimal downtime.

Benefits

- Improves fuel efficiency in power plants with precise particle size control.

- Minimizes operational costs with durable design for extended service life.

- Enhances energy savings through optimized turbine classifier technology.

- Increases production line flexibility by accommodating varied material inputs.

- Ensures seamless integration with existing systems for streamlined upgrades.

- Applications

- Coke, Bioplastics, Solid fuels, Masterbatch, Agrichemicals, Coal, Polyolefins, Steelmaking, Fertilizers, Cement

- End products

- Metallurgical coke, Polyethylene granules, Npk fertilizer blends, Anthracite, Biodegradable plastics, Portland cement, Ammonium nitrate fertilizer, Urea granules, Reinforcing steel bars, Pelleted solid fuels, Bituminous coal, Polypropylene pellets

- Steps before

- Grinding, Pulverizing, Drying

- Steps after

- Filtration, Particle size control, Combustion

- Input ingredients

- pulverized fuel, solid fuel products, coal, coke

- Output ingredients

- finer solid fuel products, pulverized coal, pulverized coke, particles with high fineness specifications, products with particle size control

- Market info

- Schenck Process is known for its expertise in material handling, weighing, feeding, and automation solutions. The company has a strong reputation for delivering high-quality engineered-to-order equipment for diverse industries, backed by innovative technology and customer-centric service.

- Classifier Type

- Static / Dynamic

- Model

- Raymond® Turbine Classifier

- Compatibility

- Roller Mills / Bowl Mills

- Particle Size Control

- 85% passing 200 mesh

- Fineness

- 85% and above passing 200 mesh (<15R 75 microns)

- Operational Environment

- High Rotational Speeds

- Design

- Mechanically robust for high-speed operation

- Retrofitting

- Available for existing mills

- Performance Enhancement

- Enhances system performance

- Fuel Compatibility

- Pulverized solid fuels

- Working Mechanism

- Static and dynamic classification

- Automation Level

- PLC / Manual

- Changeover Time

- Rapid for system flexibility

- Batch vs. Continuous Operation

- Continuous

- Particle Size Control

- High fineness specifications

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Independent or circuit use

- Yes

- Machine footprint

- Varies

- Compact design available

- Turbine size

- Customizable per application

- Configuration

- Static and dynamic

- Feed/Discharge method

- Independent or in circuit

- Retrofit capability

- Yes, for existing systems

- Design

- Hybrid - static and turbine combined

- Rotational speed

- High, dynamically analyzed

- Configuration type

- Static / Dynamic

- Integration possibilities

- Can integrate with existing systems

- Flexibility

- Can retrofit existing systems

- Material of construction

- Corrosion-resistant

- Size configuration

- Varied sizes available