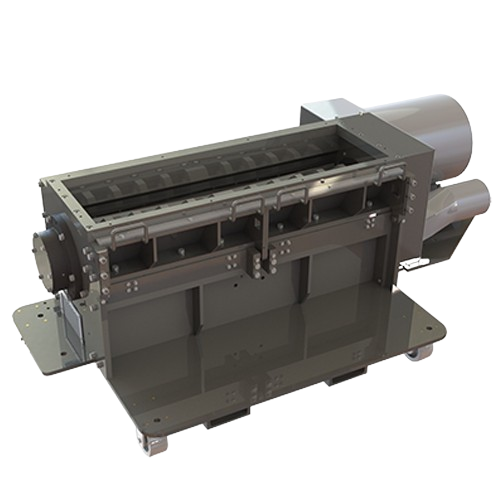

Thermoforming granulators for efficient material processing

Efficiently recycle and optimize your plastic waste by transforming it into high-quality granules, seamlessly integrating into your production line for enhanced material handling and reduced waste.

Granulates Thermoformed Plastics and Film Scrap

AEC’s Thermoforming Granulators are engineered to efficiently granulate thermoformed plastics and film scrap, ideal for industries like packaging and recycling. These machines utilize high-speed processes to manage continuous operations with exceptional throughput. Designed for seamless integration, they handle edge trim and industrial plastic waste, producing granules for disposable food containers, blister packaging, and more. With customizable configurations, the granulators support remote monitoring and control for enhanced operational efficiency. Constructed for durability in demanding environments, they offer scalable solutions tailored to specific production needs, backed by AEC’s engineering expertise and support.

Benefits

- Enhances production efficiency with seamless integration into existing lines.

- Supports high-speed processing to maximize throughput and reduce bottlenecks.

- Customizable configurations enable tailored solutions for diverse processing needs.

- Reduces operational costs with remote monitoring and automation capabilities.

- Durable construction ensures longevity in demanding industrial environments.

- Applications

- Thermoformed plastics, Industrial plastic waste, Plastic sheets, Edge trim, Film scrap, Packaging materials

- End products

- Plastic lids, Film rolls, Disposable food containers, Credit card covers, Plastic trays, Retail blister packs, Protective packaging inserts, Blister packaging, Clamshell packaging, Custom plastic enclosures

- Steps before

- Material Handling, Blending, Drying

- Steps after

- Reclaim, Packing, Conveying

- Input ingredients

- plastic materials, thermoformed sheets, edge trims

- Output ingredients

- granulated plastic, recycled pellets, reclaimed material

- Market info

- AEC (ACS Group) is known for manufacturing industrial equipment such as cooling, heating, and conveying solutions, serving various industries with a reputation for high-quality engineered-to-order systems and reliable customer support.

- Material processing capability

- Wide variety of materials

- Infeed system

- Expertly designed for smooth operation

- Operation speed

- Full-speed operation

- Throughput requirements

- Multitude of materials

- Series type

- Feedroll FRE Edge Trim Series / FRC Crusher Series / FRV Versatile Series

- Series type

- WG Series / WG1200 Series / WG1400 Series

- Material throughputs

- Varies by system

- Material compatibility

- Wide variety of materials

- Infeed systems

- Smooth processing from startup to full-speed

- Automation level

- Varies by system

- Changeover time

- Optimized for efficiency

- Batch vs. continuous operation

- Batch / Inline Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Material throughput capacity

- Variable

- Machine footprint

- Compact / Large

- Feed method

- Infeed system

- Discharge method

- Continuous

- Control panel type

- HMI / Touchscreen

- Integration possibilities

- PLC / SCADA