Air separator for polymers and plastics

Ensure high-purity plastic pellets by efficiently separating fine dust and streamers before packing and loading.

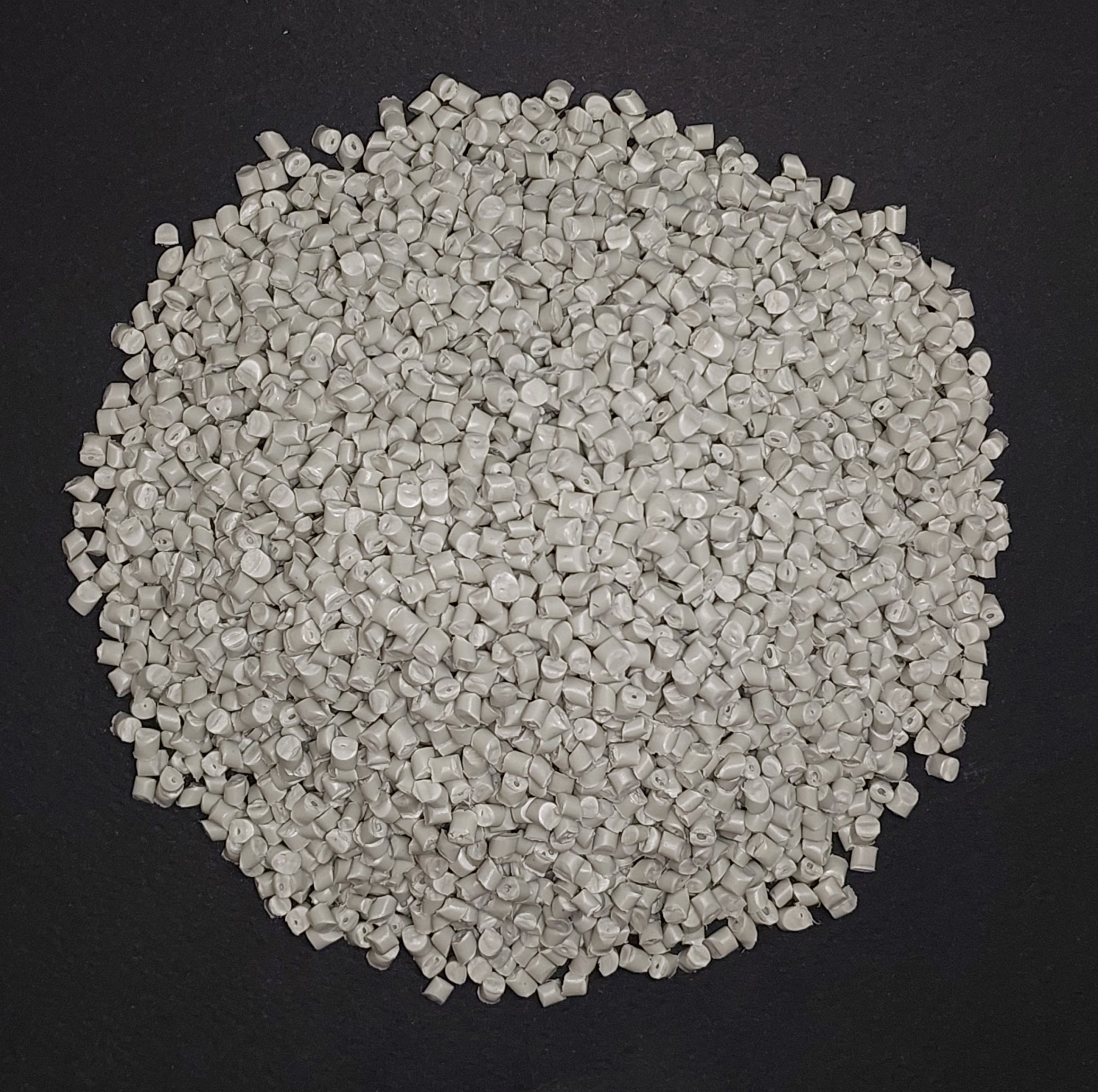

Separates Dust from Plastic Pellets

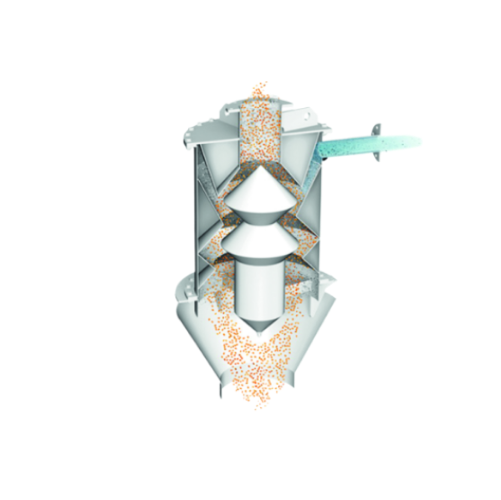

The KWS Cascade Air Separator from Zeppelin Systems is designed to streamline the production process by efficiently separating fine dust from plastic pellets. This separator leverages a counterflow principle, maintaining consistent separation performance throughout its operation. The gravimetric feeding allows it to integrate seamlessly into high-capacity production lines, capable of handling up to 200 metric tons per hour. Ideal for applications in polymers and complex plastics, it ensures product purity prior to packing and loading. Built with maintenance-free operation in mind, it lacks rotating or wearing parts, minimizing downtime and maintenance efforts. Its design also eliminates dead space, virtually eradicating the risk of material cross-contamination. This equipment fits snugly into existing operations with easy installation and processing versatility, making it suitable for diverse sectors like chemical, plastics, rubber, and tire industries.

Benefits

- Enhances product purity by effectively removing dust from plastic pellets.

- Minimizes maintenance needs with a design free of rotating or wearing parts.

- Integrates smoothly into high-capacity lines with a gravimetric feeding system.

- Prevents material mixing with dead space-free design.

- Simplifies installation and operation in diverse industrial settings.

- Applications

- Polymers, Complex plastics

- End products

- Acrylonitrile butadiene styrene (abs) pellets, Polypropylene granules, Pvc resin, High-density polyethylene (hdpe) granulates, Plastic pellets

- Steps before

- Purification, Emulsification, Drying

- Steps after

- Packing, Loading

- Input ingredients

- pellets, fine dust particles, long streamers

- Output ingredients

- cleaned pellets, separated dust

- Market info

- Zeppelin Systems excels in designing and manufacturing high-quality bulk material handling and processing equipment. Renowned for its engineering expertise, the company serves industries including plastics, chemicals, and food, ensuring efficient, reliable, and innovative solutions tailored to customer needs.

- Capacity

- Up to 200 metric tons per hour

- Automation

- Manual / Automatic

- Separation efficiency

- Consistent throughout operation

- Product handling

- Gentle

- Design

- Eliminates dead space

- Maintenance

- Maintenance-free

- Cross-section

- Circular

- Working mechanism

- Gravimetric feeding

- Separation method

- Counterflow principle

- Setup and installation

- Easy setup and installation

- Product handling

- Gentle

- Efficiency

- Consistent separation efficiency

- Maintenance

- Maintenance-free

- Operation duration

- Throughout the entire duration

- Design

- No dead space

- Cleanability

- Easy setup and installation

- Density/particle size

- Used for polymers and complex plastics

- Machine Footprint

- Compact due to reduced height

- Feed Method

- Gravimetric or rotary feeder

- Discharge Method

- No intake or discharge feeders required

- Shape

- Circular cross-section

- Discharge method

- Gravimetric / Rotary feeder

- Compact footprint

- Reduced height design

- Integration capabilities

- Easy setup and installation

- Circular cross-section

- Yes