High pressure homogenization for polymer nanodispersions

Effortlessly handle challenging products with fibers or solid parts, preventing clogging while delivering consistent homogenization at high pressures. Adaptable for a variety of demanding applications from polymers to industrial fluids.

Homogenizes and Pumps High-Fiber and Solid-Loaded Liquids

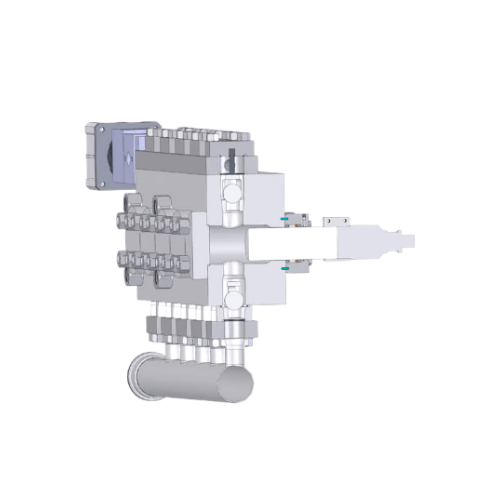

The OpenXFLO Compression Block from GEA is engineered for seamless integration into high-pressure homogenization lines, specifically for challenging industrial applications like latex, polymers, and nanodispersions. Its unique compression head design allows the free flow of products containing fibers or solid parts without accumulation or clogging, ensuring uninterrupted continuous processing. Designed to handle pressures up to 150 bar, with optional configurations exceeding 700 bar, it is ideal for producing end-products such as polymer films, nanoscale drug systems, and high fiber drinks. The homogenizer’s springless valve configuration enhances reliability in harsh operational conditions, while corrosion-resistant materials extend its service life in diverse industries, from food and pharmaceuticals to oil and gas. Easy to clean and maintain, OpenXFLO supports CIP systems, offering minimal downtime and maximum efficiency. For those requiring specialized engineering, customization options are available to meet specific process demands.

Benefits

- Ensures smooth production flow by eliminating blockages from fibers and solids.

- Increases operational efficiency with continuous high-pressure capabilities.

- Customizable pressure settings accommodate demanding industrial processes.

- Reduces maintenance downtime with easy-to-clean, corrosion-resistant materials.

- Enhances product quality by providing uniform homogenization across diverse applications.

- Applications

- Polymers, Industrial fluids, Nanodispersions, High fiber products, Products with solid parts, Slurries, Latex

- End products

- Latex gloves, High fiber drinks, Polymer films, Lubricating oils, Ceramic slurries, Chunky soups, Nanoscale drug delivery systems

- Steps before

- Mixing, Blending, Grinding, Cleaning

- Steps after

- Stabilization, Packing, Coating, Quality Control

- Input ingredients

- latex, polymers, nanodispersions, slurries, products containing high fibers, solid parts, conglomerated fibers

- Output ingredients

- homogenized liquids, stabilized products, products with no accumulations, products with enhanced shelf life, high pressure-treated products

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Pressure Rating

- Up to 150 bar

- Special Pressure Execution

- Up to 700 bar

- Pumping Valve Configuration

- Without springs

- Free Product Flow

- Up to homogenizing valve

- Pumping Capacity

- Industrial scale

- Homogenization Application

- Latex, polymers nanodispersions, slurries, high fibers or solid parts

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Fiber Content

- High / Low

- Solid Particle Size

- Small / Medium / Large

- Slurry Compatibility

- Yes

- Latex and Polymer Compatibility

- Yes

- Homogenization Application

- High pressure

- Machine Footprint

- Compact design

- Design Concept

- Innovative/Free passage design

- Head Type

- Patented compression head

- Pressure Rating

- 150 bar standard

- Up to 700 bar on request

- Valve Configuration

- Without springs, optimized design

- Flow Capability

- Free flow for fibers and solids

- Material Resistance

- Corrosion-resistant materials

- Optional compression head

- OpenXFLO®

- Valve configuration

- Springless design

- Pressure rating customization

- Up to 700 bar