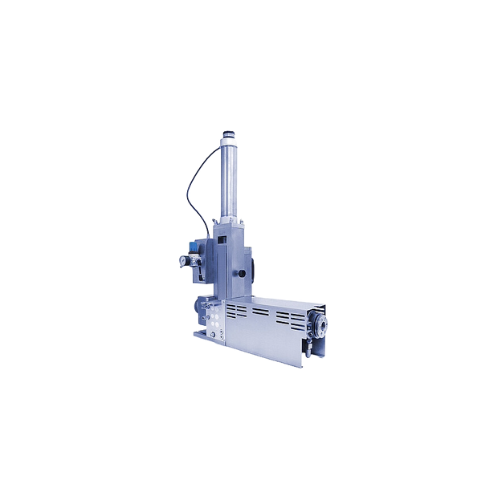

Measuring extruder for small sample simulation

Optimize your production process with this precise extruder, designed to simulate real-world manufacturing environments without interrupting ongoing operations, delivering accurate measurements for melt pressure, torque, and temperature, even with minimal sample material.

Performs Extrusion, Homogenization, and Quality Measurement

The Brabender Measuring Extruder and Grooved Extruder 19/20 offers robust solutions for continuous extrusion processes across plastics, rubber, food, and wire industries. Equipped with advanced torque measurement and temperature control, this equipment is essential for achieving precision in melting, mixing, and homogenizing applications. The integrated spiral tooth gear clutch with the Brabender drive unit ensures efficient material handling, while the continuous monitoring of melt pressure and temperature aids in maintaining product consistency. Commonly used for producing plastic pellets, rubber sheets, and extruded food products, its versatility supports both R&D and pilot operations. With options for film-blowing die heads and pelletizers, the system seamlessly integrates into existing production lines. Its operational efficiency is complemented by energy-saving features and easy connectivity to remote monitoring systems. Constructed from high-grade materials, it withstands corrosive environments and meets industry standards for longevity and low maintenance, making it an asset in polymer and food processing lines.

Benefits

- Enhances production efficiency by maintaining consistent product quality with precise temperature and pressure control.

- Minimizes material waste with small sample processing capabilities, ideal for R&D and pilot projects.

- Reduces operational costs through energy-efficient motor and integrated monitoring systems.

- Allows for flexible production setups with easy integration into existing lines and versatile die head options.

- Optimizes cleaning processes and maintenance with corrosion-resistant construction and user-friendly design.

- Applications

- Food, Feed, Pasta, Laboratory, Wire, Plastics, Rubber, Film, Production

- End products

- Laboratory samples, Extruded food products, Insulated wire coatings, Rubber sheets, Production-oriented prototypes, Animal feed pellets, Pasta shapes, Plastic pellets, Plastic films

- Steps before

- Material Preparation, Material Feeding, Pre-heating

- Steps after

- Forming, Cooling, Cutting, Pelletizing, Quality Inspection

- Input ingredients

- sample material, raw polymers, material for extrusion, plastic granules, rubber compounds, food ingredients for extrusion

- Output ingredients

- extruded product, pellets, films, strands, coated wires, pasta products, tubings, ribbons

- Market info

- Brabender is renowned for producing high-quality, engineered-to-order lab equipment for material testing, particularly in food and plastics industries, specializing in precision instruments for measuring, preparation, and processing.

- Continuous recording

- Torque, melt and control temperatures, melt pressure

- Sample size

- Small amounts

- Process simulation

- Realistic simulation without interrupting ongoing production

- Die configuration

- Spiral tooth gear clutch

- Temperature control

- Heated barrel

- Operation

- Continuous

- Integration

- Connected via spiral tooth gear clutch to the drive unit

- Cooling option

- Air and water

- Pelletizing method

- Uniform pelletizing with variable sizes

- Noise level

- Low-noise operation

- Control

- Manual or via PC

- Speed control

- Continuously adjustable

- Film quality

- Excellent

- Film take off speed

- High

- Temperature conditioning

- Accurate

- Diameter range

- 1 mm to 7 mm

- Knife extension

- 4 to 8 knives

- Realistic simulation of production processes

- Without interrupting ongoing production

- Automation level

- Continuous recording of torque, melt and control temperatures as well as melt pressure

- Batch vs. continuous operation

- Continuous

- Integration with Brabender drive unit

- Spiral tooth gear clutch

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Extruder barrel diameter

- 19 mm - 20 mm

- Screw diameter

- 19 mm - 20 mm

- Discharge method

- Screw to die head

- Control panel type

- Ergonomic control panel

- Discharge method

- Screw to die head

- Integration possibilities

- Spiral tooth gear clutch

- Adjustable speed

- Continuously adjustable