Cutting mill for soft and medium-hard materials

Efficiently reduce the size of diverse materials with precision cutting and shearing forces, enhancing your process through rapid, reliable handling of soft and medium-hard samples. Ideal for routine applications requiring versatile adaptation to varied sample properties.

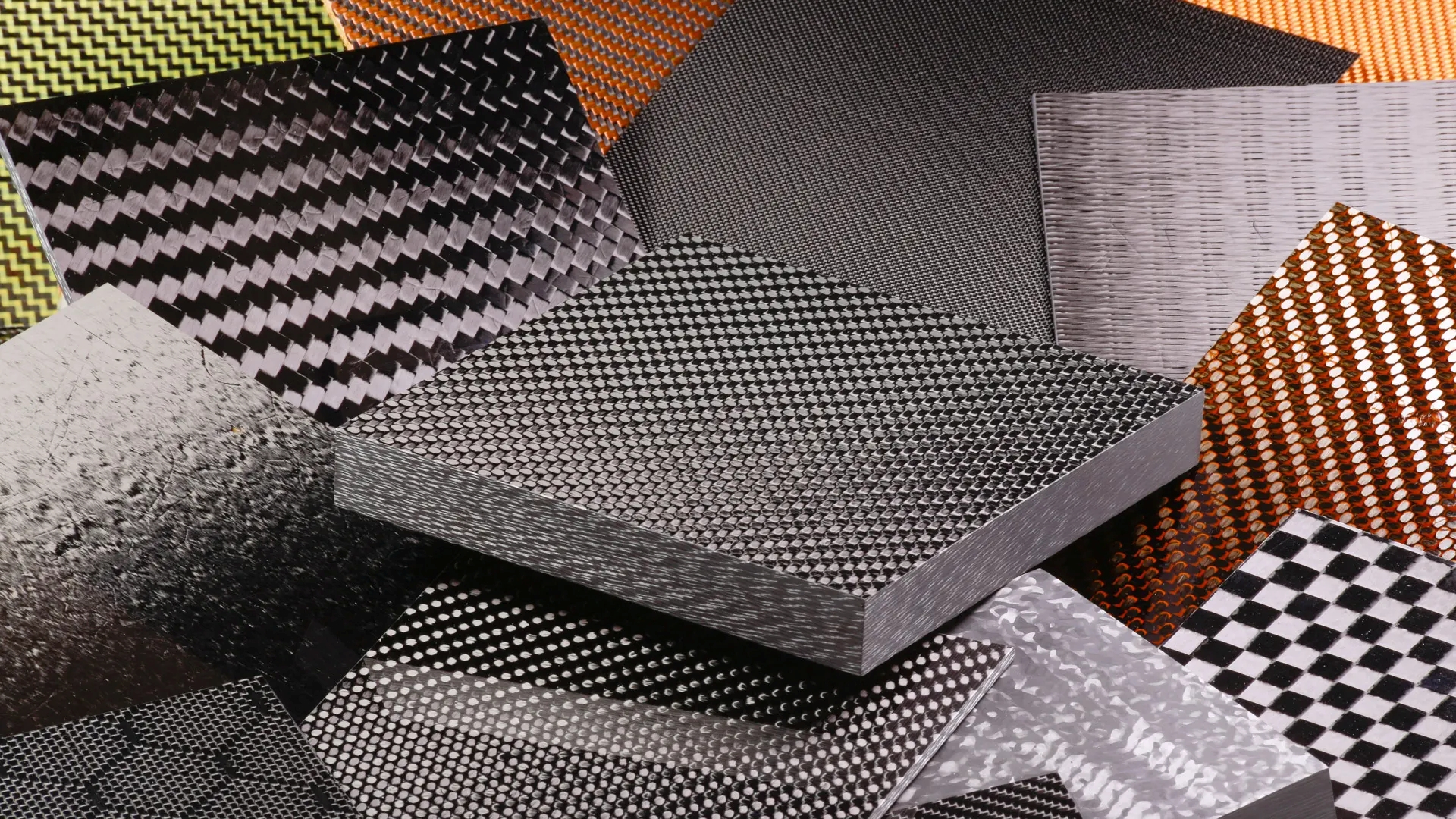

Processes and Reduces Diverse Material Consistencies

The Cutting Mill SM 100 from Retsch is a fundamental solution for routine sample preparation, offering efficient size reduction through cutting and shearing forces. Specially designed for diverse materials, it handles soft, medium-hard, and fibrous substances with precision. The SM 100 facilitates various applications in agriculture, food, pharmaceuticals, and recycling industries, generating consistent particle sizes such as PET bottle flakes, pharmaceutical powders, and shredded wood chips. With a rotor speed of 1,500 min⁻¹, this mill ensures rapid processing, while interchangeable rotors and sieves allow customization to specific operational needs. The mill integrates seamlessly into both batch and routine production lines, featuring easy cleaning with smooth surfaces and quick disassembly. Available in stainless or heavy-metal-free steel, it meets stringent safety and material compatibility standards to support compliant processing in sensitive environments. The modular design encourages further customization, whether enhancing throughput with different hopper types or optimizing fineness with a variety of bottom sieves.

Benefits

- Enhances material processing consistency with precise size reduction.

- Minimizes contamination risk through easy-clean design with smooth surfaces.

- Offers versatility with customizable rotors and sieves to match specific material properties.

- Supports diverse industries, ensuring broad application flexibility.

- Increases operational safety with high-standard construction ensuring reliable use.

- Applications

- Food, Chemistry, Non-ferrous metals, Recycling, Medicine, Biology, Wood, Waste, Environment, Textiles, Plastics, Resins, Agriculture, Rubber, Electronics, Engineering, Pharmaceuticals

- End products

- Resin powder, Textile shreds, Leather scraps, Shredded wood chips, Electrical wire granules, Animal feed pellets, Plastic film chips, Mixed material granules, Pelletized feed ingredients, Walnut pieces, Powdered food additives, Processed plant fiber, Rubber crumbs, Bone meal, Shredded non-ferrous metal pieces, Polymer granules, Refuse-derived fuel granules, Straw fibers, Fish meal, Pet bottle flakes, Plastic toy parts, Aluminum powder, Lignite granules, Recycled paper fibers, Livestock feed supplements, Circuit board fragments, Spice powder, Pharmaceutical pill powder, Cardboard pulp

- Steps before

- Drying, Sample Preparation, Pre-sorting, Initial Cleaning

- Steps after

- Packing, Sieving, Analysis, Sample Collection

- Input ingredients

- soft materials, medium-hard materials, tough materials, elastic materials, fibrous materials, heterogeneous mixes, PET preforms, aluminium slag, animal feed, bones, cables, cardboard, electronic components, feed pellets, foils, food, leather, lignite, material mixtures, non-ferrous metals, paper, pharmaceutical products, plant materials, plastic toys, plastics, polymers, refuse derived fuels, resins, rubber, spices, straw, textiles, waste, wood

- Output ingredients

- size-reduced materials, final fineness materials, uniform particle size materials

- Market info

- Retsch is renowned for manufacturing high-quality laboratory equipment, specializing in milling, sieving, and assisting technologies for sample preparation and characterization, known for precision, reliability, and innovation in the scientific and industrial laboratory markets.

- Feed size

- < 60 x 80 mm

- Final fineness

- 0.25 - 20 mm

- Rotor speed

- 1, 500 min-1

- Rotor peripheral speed

- 9.4 - 11.4 m/s

- Rotor diameter

- 129.5 mm

- Sieve size

- 0.25 / 0.50 / 0.75 / 1.00 / 1.50 mm trapezoid holes

- 2.00 / 4.00 / 6.00 / 8.00 / 10.00 / 20.00 mm square holes

- Drive power

- 1.5 kW

- Electrical supply data

- Different voltages

- Protection code

- IP 54

- Dimensions (W x H x D)

- 582 x 1675 x 700 mm (with base frame and standard hopper)

- Net weight

- ~ 73 kg without hopper, rotor and base frame

- Working Mechanism

- Cutting and shearing

- Feed Size

- < 60 x 80 mm

- Final Fineness

- 0.25 - 20 mm

- Cleaning Method

- Quick and easy cleaning

- Installation

- Tabletop or base frame

- Safety Standards

- Highest safety standards

- Automation Level

- Manual operation

- Rotor Speed

- 1, 500 min-1

- Discharge Method

- Gravity outlet

- Cleanability

- Quick and easy cleaning due to smooth surfaces

- Density/particle size

- Soft, medium-hard, elastic, fibrous materials

- Weight

- ~ 73 kg without hopper, rotor, and base frame