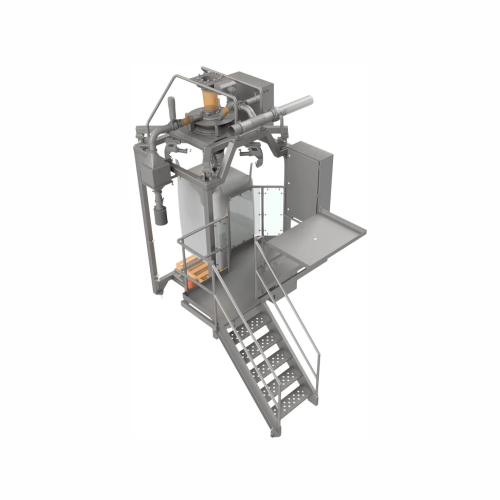

Sanitary bulk bag filling system

Streamline your powder handling process with a system designed to improve stability and accuracy while reducing dust during bulk bag filling and packaging operations.

Fills, Weighs, and Densifies Bulk Bags

The RELCO® Bulk Bag Filler from Kovalus Separation Solutions is engineered for precise and sanitary filling of bulk bags, catering to diverse industries such as dairy, food, beverage, and more. This equipment is designed with robust stainless steel construction, ensuring corrosion resistance and compliance with 3A standards and USDA guidelines. It features a rotating bag loop hanger system for efficient loading, while its integrated scale controller ensures accurate weight measurements. Equipped with a tool-free disassembly design, the filler facilitates easy cleaning and maintenance. The filler includes a unique bag inflation venturi with a HEPA filter, reducing bridging and enhancing dust control during operations. It handles various bulk bag sizes with an adjustable scissor lift for consistent operator interface. Optional integrated palletizing systems are available for enhanced operational synergy.

Benefits

- Optimizes production efficiency with precise and accurate bag filling and weighing.

- Enhances operational safety and hygiene with easy-to-clean, tool-free disassembly.

- Minimizes product waste and contamination with advanced dust control and bag inflation systems.

- Increases flexibility for varied production needs with adjustable bag size capacities.

- Ensures compliance with industry standards, supporting diverse application requirements.

- Applications

- Food, Sour gas, Environmental, Gas, Textile, Automotive, Beverage, Metals, Oil, Biogas, General industrial, Pulp, Mining, Paper, Life sciences, Dairy

- End products

- Powdered milk, Metal powders, Paper additives, Chemical powders, Mineral powders, Car polish powders, Powdered sugar, Plastic granules, Whey powder, Textile processing powders, Gas purification powders, Protein supplements, Cleaning agents, Powdered flavors, Drink mixes, Environmental absorbents

- Steps before

- Powder Blending, Powder Gassing, Purification, Drying

- Steps after

- Packing, Palletizing, Sterilization

- Input ingredients

- powder, dry bulk materials, bulk bag

- Output ingredients

- filled bulk bags, packaged powder, stable bulk bag

- Market info

- Kovalus Separation is known for manufacturing industrial engineered-to-order (ETO) separation equipment, specializing in tailored solutions for complex filtration and separation needs, with a strong reputation for innovation, quality, and reliability in various industries.

- Material

- Stainless steel

- Construction

- Corrosion resistant

- Scale Controller

- Fixed-load cell set

- Disassembly Design

- Tool-free

- Bag Loop System

- Rotating bag loop hanger

- Filler Head Connection

- Tool-free exchangeability

- Venturi Inflation

- HEPA filter

- Bag Bottom Densifying

- Hydraulic scissor

- Scissor Lift Adjustment

- 45 to 72 inches

- Pneumatic Thumper

- Reduces product buildup

- Dust Collection

- Automated control valve

- Safety Circuit

- E-Stop

- Enclosure Rating

- NEMA 4

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Batch

- Changeover time

- Tool-free disassembly

- CIP/SIP

- Tool-free for ease of cleaning

- Air incorporation control

- HEPA filter for sanitary air

- Cleaning method

- Tool-free disassembly

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- Tool-free disassembly

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Density/particle size

- Variable

- Control panel type

- PLC/HMI

- Compact footprint

- Yes

- Material

- Stainless steel

- Construction

- Robust, corrosion-resistant

- Access platform

- Stainless steel

- Inflation system

- Venturi and HEPA filter

- Bag loading system

- Rotating bag loop hanger

- Filler head connection

- Tool-free

- Bag bottom densifying platform

- Hydraulic scissor

- Scissor lift adjustment

- Automatic

- Bag size compatibility

- 45 inch to 72 inch

- Control panel type

- PLC/HMI

- Integration possibilities

- Tool-free filler head connection

- Bag type adjustment

- Rotating bag loop hanger system

- Compact footprint

- Tool-free disassembly design

- Construction material

- Stainless steel