Loss-in-weight feeder for plastic compounding

Achieve precise material flow and improved production efficiency with an adaptable feeding solution tailored for continuous operation, ensuring optimal integration in complex plastic compounding processes.

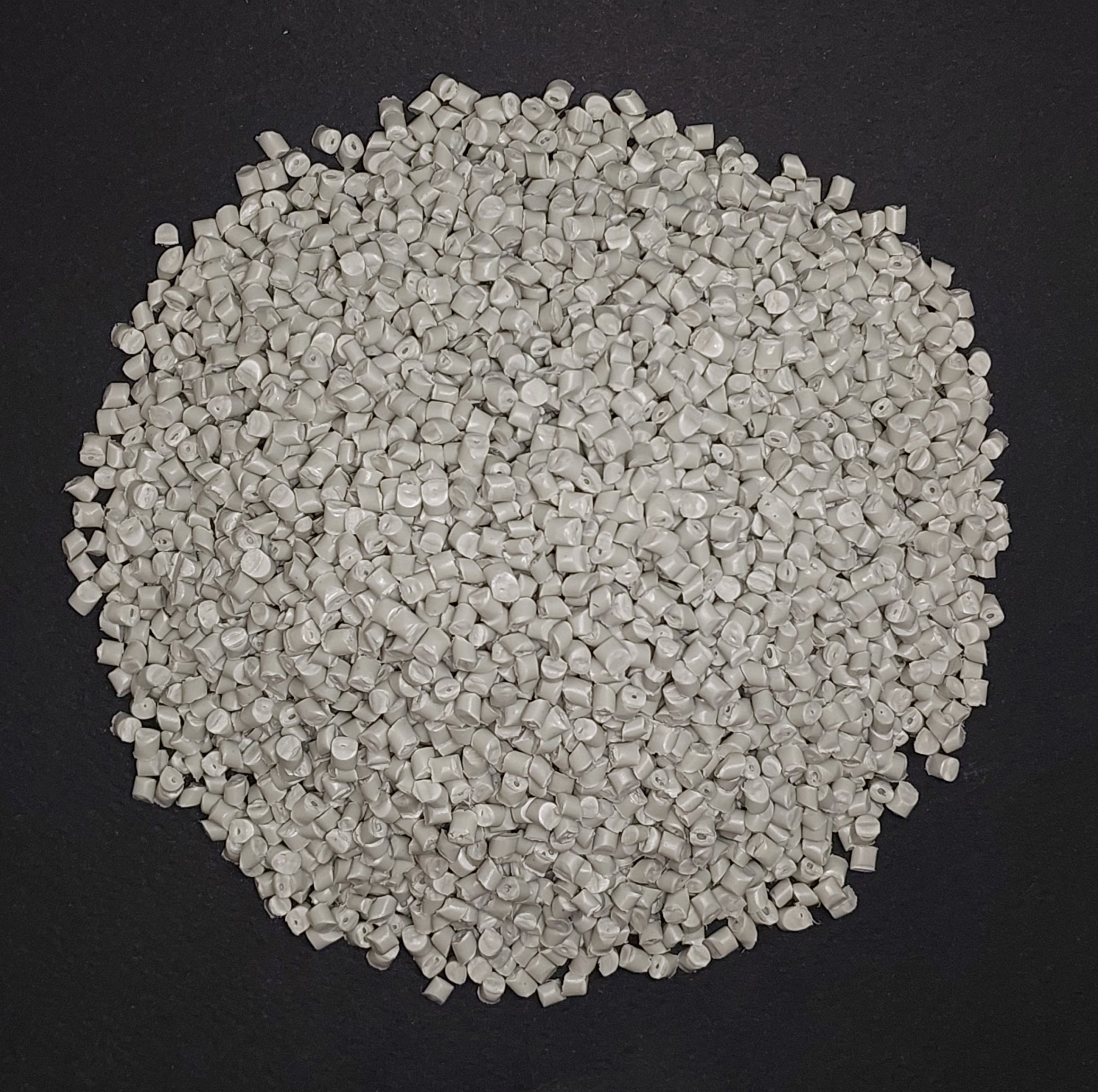

Feeds and Weighs Plastics and Granulates

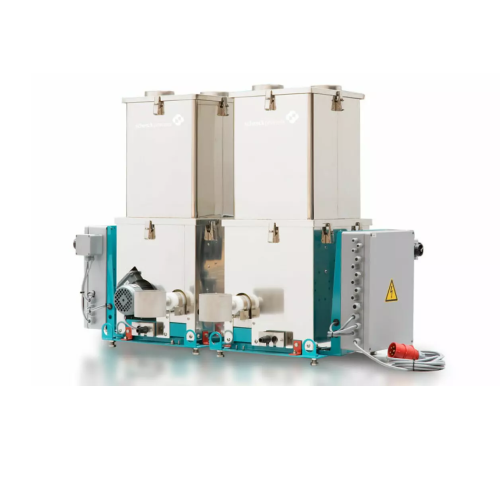

The ProFlex C from Schenck Process is a versatile loss-in-weight feeder designed for the precision dosing of powders and granulates in plastics and masterbatch production. Its unique off-center auger arrangement enables a compact installation, accommodating up to eight feeders in limited spaces. With a feed rate capacity reaching 6000 dm³/hour, the ProFlex C excels in applications requiring continuous and accurate volumetric and gravimetric feeding. The system integrates seamlessly into automated production lines with integrated measuring, control, and regulation electronics. Constructed with vertical container walls and steep wall angles, it ensures optimal material flow and minimizes residue. The ProFlex C is offered in stainless steel configurations for enhanced durability and is compliant with industry standards. Its design allows for rapid disassembly, facilitating easy cleaning and maintenance, making it ideal for environments demanding stringent hygiene and operational flexibility.

Benefits

- Enhances production efficiency with precise dosing of powders and granulates.

- Increases operational flexibility by fitting into space-constrained environments.

- Minimizes maintenance downtime through easy disassembly and cleaning processes.

- Supports scalable production with capacity to integrate up to eight feeders.

- Ensures reliable performance with specialized corrosion-resistant materials.

- Applications

- Plastic compound, Plastics, Granulate materials, Powders, Masterbatch

- End products

- Polyethylene pellets, Calcium carbonate compounds, Polypropylene granules, Nylon pellets, Talc-filled plastics, Color masterbatches, Polymer granules, Additive masterbatches, Acrylic powders, Pvc compounds

- Steps before

- Grinding, Compounding, Pre-Mixing

- Steps after

- Mixing, Extrusion, Pelletizing, Color Masterbatch Addition

- Input ingredients

- bulk materials, powders, granulate materials

- Output ingredients

- compounded plastic, masterbatch

- Market info

- Schenck Process is known for its expertise in material handling, weighing, feeding, and automation solutions. The company has a strong reputation for delivering high-quality engineered-to-order equipment for diverse industries, backed by innovative technology and customer-centric service.

- Feed rate

- 100 dm³/h - 6000 dm³/h

- Feeder sizes

- C100, C500, C3000, C6000

- Feeder type

- Loss-in-weight, Volumetric

- Dosing type

- Gravimetric / Volumetric

- Installation configuration

- Up to eight feeders

- Automation

- Integrated control and regulation electronics

- Design

- Asymmetric with steep wall angles

- Working Mechanism

- Gravimetric and Volumetric Feeding

- Integrated Steps

- Measuring, Control and Regulation Electronics

- Batch vs. Continuous Operation

- Continuous

- Changeover Time

- Rapid and Simple Disassembly

- Cleaning Method

- Simple Disassembly for Cleaning

- Automation Level

- Integrated Automation Platform

- Space Utilization

- Vertical Container Design

- Flexibility

- Off-Center Auger Arrangement for Multiple Feeder Installation

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Feed/discharge method

- Auger arrangement

- Container wall design

- Vertical with steep wall angles

- Number of feeder variants

- Four sizes

- Installation options

- Flexible, fits any available space

- Hopper design

- Asymmetric with flexible design

- Control Panel Type

- Integrated measuring, control and regulation electronics

- Feeder Design Variants

- ProFlex C500, C3000, C6000, C100

- Drive and Auger Arrangement

- Off-center, adaptable during assembly

- Installation Options

- Space-saving, flexible installation, up to eight feeders

- Discharge Side

- Easy change of discharge / drive side

- Electronic Components

- From junction boxes to complete electronic controls