Counterflow separator for polymer pellet cleaning

Achieve unparalleled pellet purity with efficient dust and streamer removal, boosting the quality of your polymer production with seamless integration into pneumatic conveyor systems.

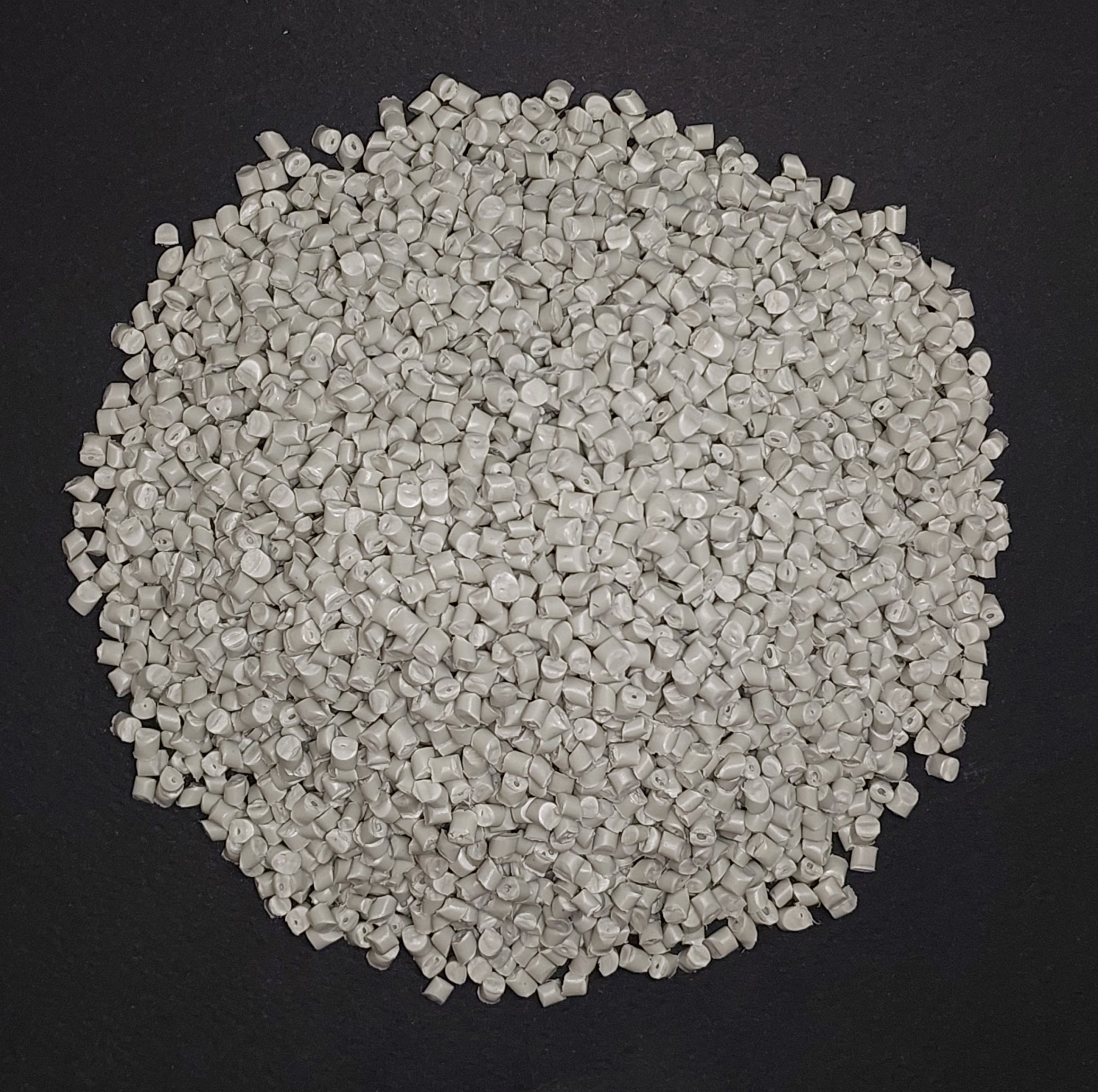

Separates and Cleans Polymer and Rubber Granules

The GTS Counterflow Pellet Separator from Zeppelin Systems is designed for polymer, plastics, rubber, and tire manufacturers seeking efficient cleaning and separation solutions. This equipment excels in removing fine dust particles and long streamers from products like polyethylene and polypropylene granules. Utilizing particle acceleration and a 180° air stream deflection, it ensures consistent separation efficiency throughout its operation.

Capable of handling up to 120 metric tons per hour, the GTS separator integrates seamlessly into pneumatic conveyor systems, supporting continuous and high-speed operations. Its maintenance-free design, without any rotating parts, reduces downtime and operational costs. Custom configurations allow adaptation to specific product and throughput requirements, while the option for gravimetric feeding enhances versatility.

Constructed for durability, the GTS separator thrives in demanding environments, maintaining its high separation efficiency over time. Its straightforward setup and ease of installation make it a reliable cornerstone in any production line, ensuring the delivery of high-quality polymer and rubber granules.

Benefits

- Ensures high product quality by effectively removing fine dust and streamers.

- Minimizes maintenance costs with a design free from rotating or wearing parts.

- Enhances production efficiency with its capacity to handle up to 120 metric tons per hour.

- Adapts to various production needs with customizable configurations.

- Simplifies integration and setup, reducing installation time and effort.

- Applications

- Polymers, Tire industry, Rubber, Plastics

- End products

- Polyethylene pellets, Styrene-butadiene rubber products, Polystyrene beads, Polypropylene granules, Tire treads, Thermoplastic elastomers, Synthetic rubber compounds, Butadiene rubber compounds, Rubber granules, Polyvinyl chloride beads

- Steps before

- Pelletization, Pneumatic conveying, Material sourcing

- Steps after

- Packing, Storage, Quality control, Material blending

- Input ingredients

- pellets, dust particles, long streamers, angel hairs

- Output ingredients

- cleaned pellets, separated dust particles, removed streamers

- Market info

- Zeppelin Systems excels in designing and manufacturing high-quality bulk material handling and processing equipment. Renowned for its engineering expertise, the company serves industries including plastics, chemicals, and food, ensuring efficient, reliable, and innovative solutions tailored to customer needs.

- Capacity

- Up to 120 metric tons per hour

- Separation Efficiency

- Maximum

- Operation Type

- Counterflow

- Automation

- Manual / Auto

- Particle Separation

- Finest dust and long streamers

- Separation Mechanism

- 180° deflection of air stream

- Integration Type

- Pneumatic conveyor systems

- Feeding Type

- Gravimetric

- Construction Design

- Maintenance-free

- Kinetic Energy Use

- Yes

- Output Method

- Via downstream rotary feeder

- Separation efficiency

- High

- Pneumatic conveyor integration

- Direct

- Automation level

- Automated

- Batch vs. continuous operation

- Continuous

- Maintenance-free design

- No rotating/wearing parts

- Gravimetric feeding

- Available

- Easy setup and installation

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Discharge method

- Gravimetric via downstream rotary feeder

- Tank shape and size

- Not specified

- Integration possibilities

- Direct integration into pneumatic conveyor systems

- Control panel type

- PLC-controlled

- Individual customization

- Customization to suit product and throughput