Gravimetric loading sifter for dust and streamer removal

Optimal for removing dust and streamers, this compact sifter ensures your polymers and plastics are screened with precision, enhancing product quality while maintaining high throughput in continuous operations.

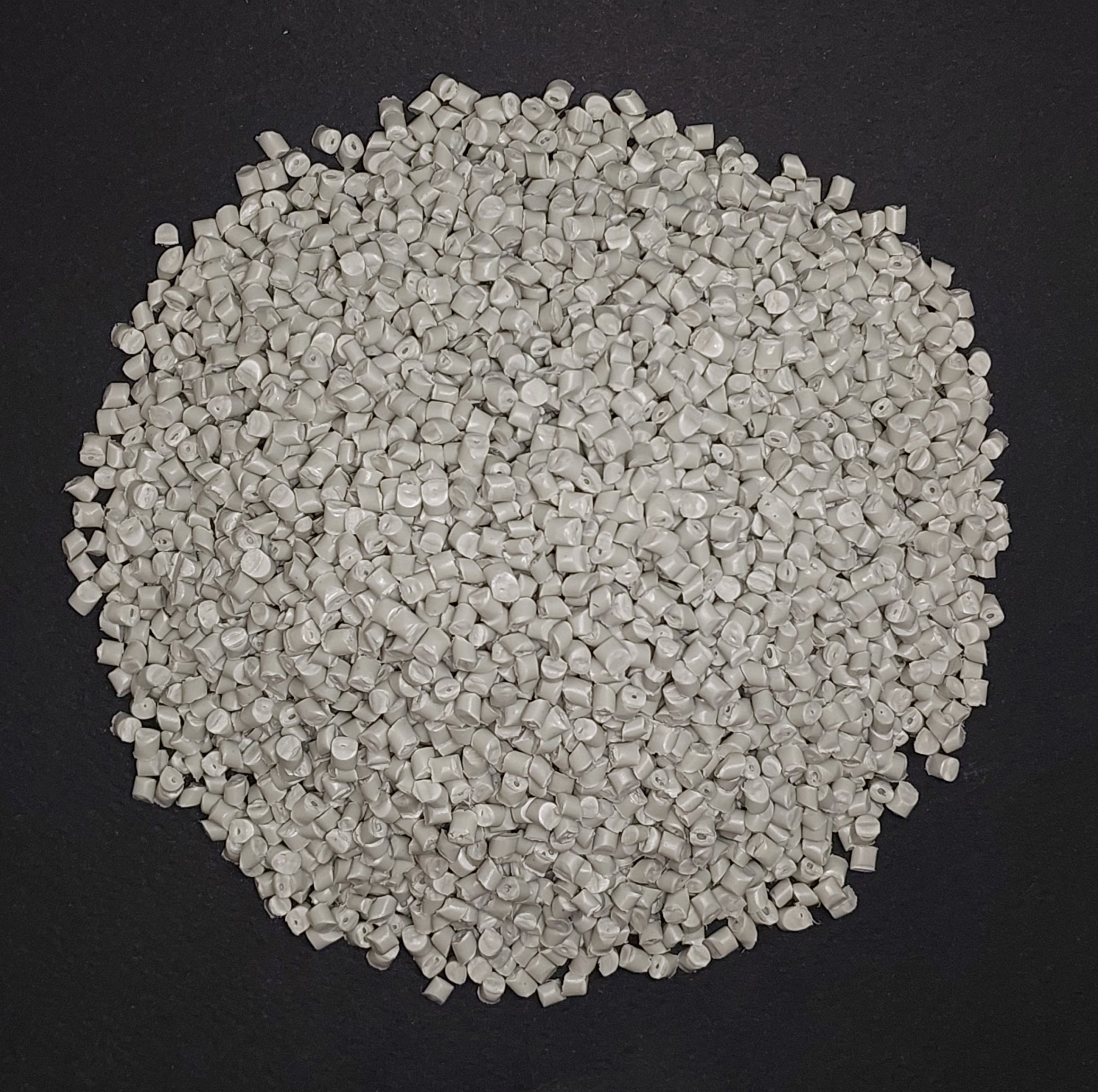

Separates Dust and Streamers from Polymeric Granules

The FVS Sifter from Zeppelin Systems is a highly efficient solution designed for the separation of dust and long streamers from polymeric granule products, such as polyethylene and polypropylene. Utilizing a gravimetric feeding system, the sifter integrates seamlessly into continuous loading processes, maintaining consistent separation efficiency without the need for additional intake or discharge feeders. It can handle up to 235 metric tons per hour, making it ideal for high-throughput operations in the plastics and chemical industries. The compact and retrofit-friendly design makes installation straightforward, and its gentle, air counterflow cleaning method ensures that granules remain intact while dust is effectively removed. The FVS Sifter is engineered for minimal maintenance and quick integration into existing systems, enhancing production line efficiency and product purity.

Benefits

- Maximizes granule purity with precise dust separation.

- Easily integrates into existing production lines to minimize installation time.

- Increases operational efficiency without the need for additional feeders.

- Supports continuous high-throughput applications up to 235 t/h.

- Reduces maintenance with a compact design requiring minimal cleaning.

- Applications

- Polymers, Complex plastics

- End products

- Polyethylene pellets, High-density polyethylene (hdpe) granules, Polypropylene granules, Pvc granules, Abs plastic beads, Pet plastic pellets, Low-density polyethylene (ldpe) pellets

- Steps before

- Storage, Transport to Silo, Silo Loading

- Steps after

- Packing, Loading

- Input ingredients

- pellets, dust, long streamers, polymers, complex plastics

- Output ingredients

- cleaned pellets, separated dust

- Market info

- Zeppelin Systems excels in designing and manufacturing high-quality bulk material handling and processing equipment. Renowned for its engineering expertise, the company serves industries including plastics, chemicals, and food, ensuring efficient, reliable, and innovative solutions tailored to customer needs.

- Capacity

- up to 500 metric tons per hour

- Gravimetric loading capacity

- up to 235 t/h

- Design

- Extremely compact

- Operation

- No intake or discharge feeders required

- Separation efficiency

- Consistent throughout operation

- System Type

- Closed system

- Cleaning method

- Gentle on products

- Integration

- Easy integration and installation

- Functionality

- Separation of finest dust particles and streamers

- Application suitability

- Final or second screen

- Applicable materials

- Polymers and complex plastics

- Integration feasibility

- Easy to retrofit

- Operation mode

- Gravimetric

- Automation level

- Manual

- Cleaning method

- Gentle on products

- Usage position

- Final or second screen

- Dust removal efficiency

- Consistent separation

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Material type

- Polymers and complex plastics

- Compact footprint

- Extremely compact design and height

- Discharge method

- No intake or discharge feeders required for operation

- Feed type

- Gravimetric feeding

- Height

- Integrated into a telescopic loading pipe

- Integration

- Very easy integration and installation

- Compact footprint

- Yes

- Control panel type

- Standard or custom interfaces available

- Discharge method

- No intake or discharge feeders required

- Integration possibilities

- Easy to retrofit

- Product integration

- Suitable for polymers and complex plastics