Pellet dryer for industrial recycling applications

Ensure precise moisture control for recycled plastic pellets and flakes with high-speed drying, enhancing the quality and consistency of your final product.

Dries and Separates Plastic Pellets and Flakes

The ECON Pellet Dryer S+L series offers efficient solutions for moisture reduction in recycling and plastic processing industries. Featuring a gearless drive for maintenance-free operation, the centrifugal drying system achieves residual humidities between 0.1 and 0.5%. With throughput capacities ranging from 500 to 10,000 kg/hr, it addresses the demands of continuous, high-speed operations. The S+L models integrate seamlessly in standalone setups or with ECON’s water treatment systems, ensuring optimal performance across various materials such as plastic pellets, PET flakes, and HDPE regrinds. Optional features include sound insulation and explosion-proof designs, providing enhanced safety and customization to meet specific industry needs.

Benefits

- Enhances moisture reduction efficiency, ensuring high-quality output for further processing.

- Minimizes maintenance costs with a gearless drive system.

- Supports high-speed, continuous operations for maximum throughput.

- Offers customization options, including sound insulation and explosion-proof designs, for industry-specific needs.

- Streamlines integration across production lines, compatible with standalone and combined setups.

- Applications

- Recycling materials, Bulk material, Flakes, Mill material

- End products

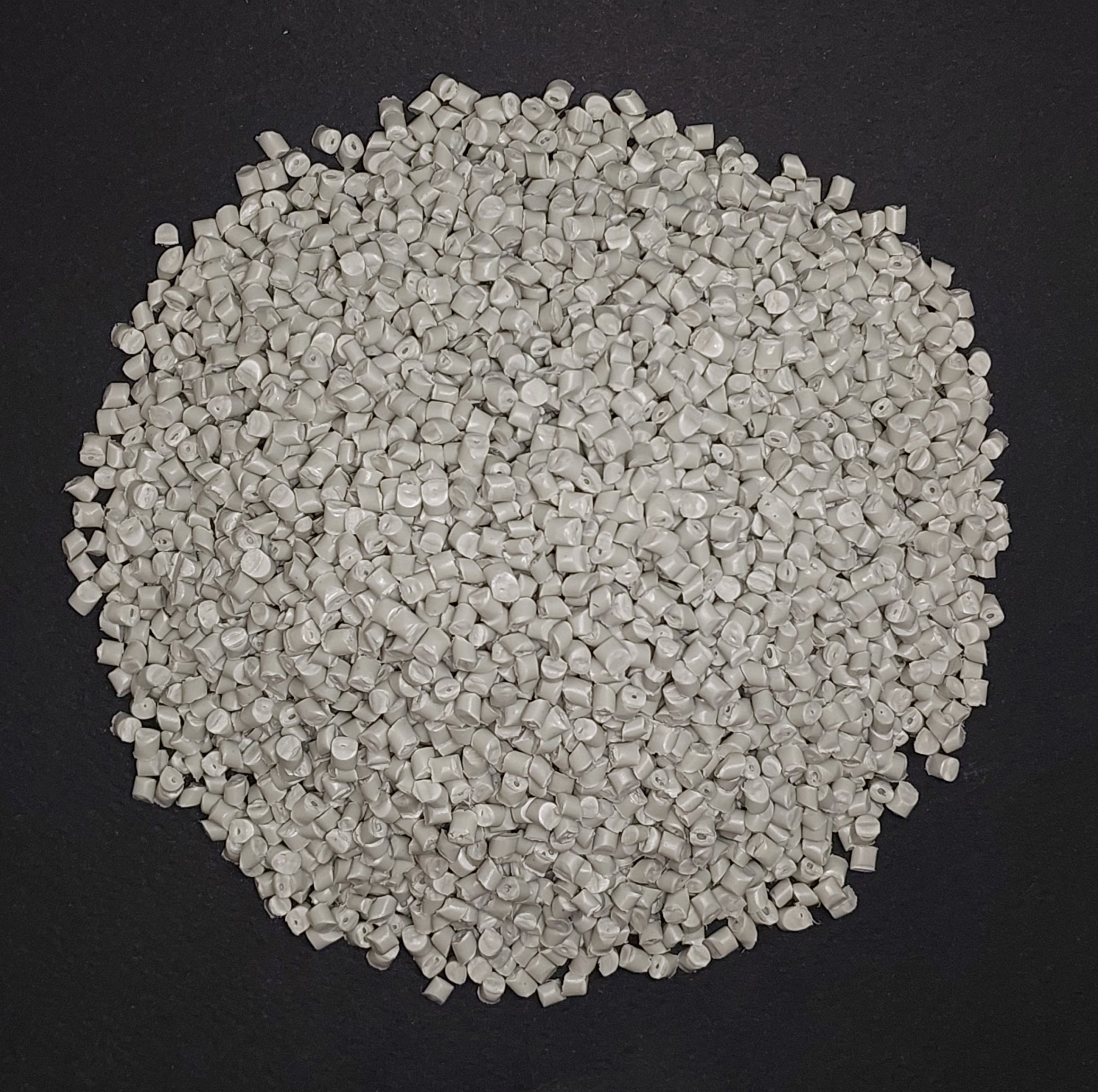

- Polypropylene granules, Recycled polymer beads, Hdpe regrind, Pet flakes, Plastic pellets, Polystyrene chips

- Steps before

- Water Treatment, Material Feeding, Bulk Handling

- Steps after

- Material Conveyance, Packaging, Quality Inspection

- Input ingredients

- granules/water mixture, bulk material, mill material, flakes

- Output ingredients

- dried granules, dried product, residual humidities 0.1% to 0.5%

- Market info

- Throughput

- 500 kg/hr

- Throughput

- 1, 200 kg/hr

- Throughput

- 2, 500 kg/hr

- Throughput

- 10, 000 kg/hr

- Residual Humidity

- 0.1–0.5%

- Drive Type

- Gearless drive

- Design Features

- Compact design and sturdy construction

- Operation Type

- Stand-alone or combined with water treatment

- Material Type

- Bulk or mill material, flakes

- Safety Features

- Explosion proof, gas proof

- Optional Components

- Sound insulation, wear-protected designs

- System Type

- Centrifugal dryer

- Working mechanism

- Centrifugal drying

- Integrated steps

- Drying, water separation

- Batch vs. continuous operation

- Continuous

- Automation level

- Automatic / Gearless drive

- Energy efficiency

- 0.1–0.5% residual humidity

- Changeover time

- Minimal (design is maintenance-free)

- Cleaning method

- Manual / Integrated sieve

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design

- Construction

- Sturdy construction

- Drive system

- Gearless drive

- Feed/discharge method

- Inlet case, tangential nozzle

- Sieve basket

- Incorporated as a sieve in the bottom

- Input Systems

- Various types available

- Optional Components

- Sound insulation, gas/explosion proof, wear-protected designs

- Drive Type

- Gearless drive