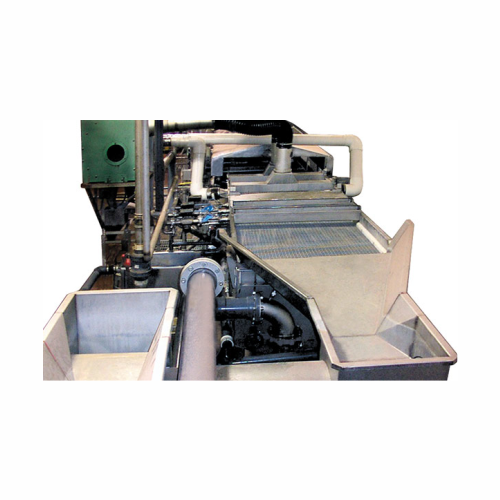

Potato slice washer for surface starch and fines removal

Ensure optimal cleaning and dewatering of potato slices while significantly minimizing fryer fuel usage and preserving product integrity with a gentle washing process that reduces surface starch and fines.

Washes, Rinses, and Dewaters Potato Slices

The Gentle Wash Potato Slice Washer system is a modular solution engineered for efficient washing, rinsing, and dewatering of potato slices in food processing. Its unique spiral action design minimizes mechanical agitation, preserving product integrity while reducing fines and surface starch. This system is ideal for potato chips, sliced potato snacks, and washed vegetable slices. Integrated with a three-stage rinsing process, it utilizes two reused water rinses and one fresh rinse for optimal water efficiency. Compatible with existing production lines, this system enhances fuel efficiency by reducing moisture content before frying. The compact design is easy to install and requires minimal floor space, perfect for continuous operations in the food and snack industries. Tailored engineering support ensures seamless integration with dewatering conveyors and water removal systems to maintain cleanliness and production throughput.

Benefits

- Enhances product integrity by minimizing mechanical agitation during washing.

- Reduces fryer fuel usage through efficient moisture removal.

- Supports water conservation with a three-stage rinsing process that reuses water.

- Easily fits into existing production lines due to its modular design.

- Optimizes floor space utilization with its compact structure.

- Applications

- Snacks, Potato chips, Food processing, Vegetables, Potato products

- End products

- Sliced potato snacks, Washed vegetable slices, Prepared vegetable products, Peeled and washed potatoes

- Steps before

- Peeling, Cutting, Potato Handling, Potato Unloading, Storage

- Steps after

- Frying, Product Cooling, Seasoning, Packaging

- Input ingredients

- potato slices

- Output ingredients

- clean potato slices, surface starch removed potato slices, dewatered potato slices

- Market info

- Heat and Control is known for its expertise in manufacturing food processing and packaging equipment, providing innovative solutions and high-quality systems for industries like snacks, prepared foods, and pharmaceuticals, with a strong reputation for reliability and technical support.

- Size

- Compact footprint

- Capacity

- Reduces fryer fuel usage

- Automation

- Easy-to-install modules

- Cleaning Method

- Reused and fresh water rinses

- Waste Management

- Reduces cleaning costs

- Dewatering

- AirSweep vacuum/blow-off system

- Type

- 3-stage washer

- Configuration Flexibility

- Modular, fits existing lines

- Working mechanism

- Spiral action gentle wash

- Integrated steps

- 3-stage washing with water reuse

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- Configurable modules

- Space efficiency

- Minimal floor space

- Energy efficiency

- Reduced fryer fuel usage

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Abrasiveness

- Low

- Heat sensitivity

- High

- Viscosity

- Medium

- Product damage risk

- Low

- Container size and shape compatibility

- N/A

- Machine footprint

- Minimal

- Discharge method

- Spiral Action

- Configuration

- Easy-to-install modules

- Feed method

- Dewatering conveyor

- Modular Configuration

- Easy-to-install modules

- Space Efficiency

- Minimal floor space

- Integration Compatibility

- Configured to fit into existing lines