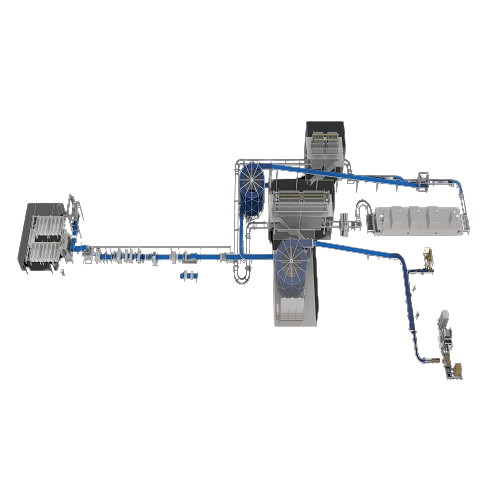

Artisan bread production line for high-volume bakeries

Optimize your artisan bakery operations with a production line that enhances product quality and streamlines processes from dough mixing to final baking, ensuring consistent, high-volume output for diverse bread varieties.

Produces and Automates Artisan Bread Varieties

AMF Bakery Systems offers the Industrial Artisan Bread Production Line, a cutting-edge solution designed to meet the needs of commercial bakeries and artisan bakery operators. This production line stands out due to its high-speed sheeting technology and modular design, enabling seamless transitions between a variety of artisanal products such as baguettes, ciabatta, and focaccia. It utilizes a continuous, automated process that integrates mixing, sheeting, fermentation, proofing, and baking, ensuring efficiency and consistency throughout.

Capable of producing up to 60,000 pieces per hour, this system supports high-volume production while preserving the delicate texture and flavor profiles characteristic of handmade breads. It features the AMFConnect™ for advanced, real-time monitoring and data-driven decision-making, enhancing operational efficiency. The use of Intralox ThermoDrive® conveyors and seamless dough troughs ensures hygiene and reduces contamination risks.

Available with customizable options, this equipment can handle diverse applications, from flatbreads to filled snacks, adapting as production needs evolve. Engineered for easy cleaning and maintenance, it includes components like the Vesta Spiral Cooler for optimized cooling and full wash-down sanitation, making it a reliable choice for scalable artisanal production.

Benefits

- Increases production capacity with up to 60,000 units per hour.

- Enhances product quality consistency through automated, stress-free operation.

- Decreases contamination risk with sanitary design and seamless components.

- Facilitates flexible product offerings with modular, easy-changeover units.

- Improves decision-making and efficiency with real-time data monitoring.

- Applications

- Baguettes, Flatbreads, Puff pastries, Swirl bread, Specialty breads, Sheeted pizza, Filled handheld snacks, Pressed pan pizza, Tin bread, Cakes, Pies, Croissants, Ciabatta, Danish pastries, Artisan bread, Focaccia

- End products

- Sourdough boules, Custard danish, Ciabatta sandwich loaves, Tin loaf, Apple pies, Focaccia bites, Neapolitan style pizza, Chocolate swirl bread, Focaccia flatbread, Stuffed bread pockets, Baguette rolls, Deep dish pizza, Sponge cakes, Almond croissants, Cheese puff pastries

- Steps before

- Dough Mixing, Fermentation, Dough Trough Handling

- Steps after

- Proofing, Baking, Cooling, Conveying, Packaging

- Input ingredients

- dough, water, flour, yeast

- Output ingredients

- artisan bread, baguettes, ciabatta, focaccia, specialty breads

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Capacity

- 60, 000 pieces per hour

- Automation

- Fully Automated

- Dough Handling

- Intralox ThermoDrive® Conveyor

- Water Absorption

- Up to 70%

- Integration

- Seamless modular integration

- Moulding

- High-speed, stress-free

- Monitoring System

- AMFConnect™

- Trough Features

- Seamless construction, welded rims

- Proofing System

- Den Boer Step Proofer

- Conveying System

- A-Series, D-Series

- Cooling System

- Vesta Spiral Cooler

- Freezing System

- Vesta Spiral Freezer

- Decorating System

- Tromp DecoJet 2

- Automation level

- High (Real-time system integration with AMFConnect™)

- Batch vs. continuous operation

- Continuous Operation

- Changeover time

- Quick (Modular units for effortless product changeover)

- Capacity

- Up to 60, 000 pieces per hour

- Monitoring system

- AMFConnect™ for real-time data access and decision making

- Cleanability

- Seamless construction, closed roll rims

- Biological compatibility

- No data available

- Corrosive resistance (e.g. acids)

- No data available

- Abrasion resistance

- No data available

- Density/particle size

- No data available

- Heat sensitivity

- High / Medium / Low

- Viscosity

- Low / Medium / High

- Container size

- Variable / Fixed

- Container shape

- Rectangular / Round / Custom

- Machine footprint

- Modular units

- Discharge method

- Continuous operation

- Shape and size

- Custom-configured conveyor

- Capacity

- Up to 60, 000 pieces per hour

- Construction

- Seamless welded

- Control panel type

- AMFConnect™

- Modularity

- Modular units for flexible production

- Trough options

- Variety of chute and gate options