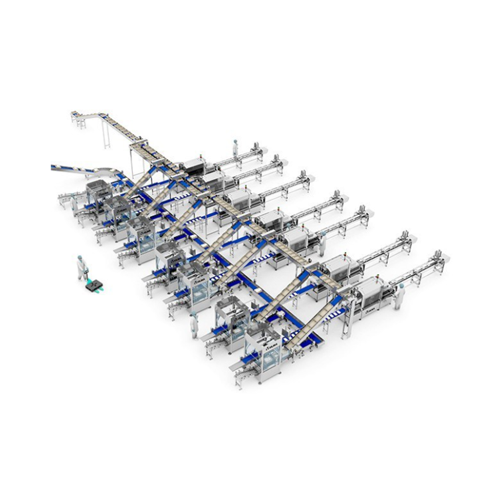

Traysealing system for chicken cut-up packaging

Optimize your poultry packaging operation with this high-speed traysealing system, ensuring hermetically sealed chicken cut-ups in modified atmospheres for extended freshness and reduced spoilage.

Seals Chicken Cut-ups in Modified Atmosphere

ULMA Packaging’s TSA Traysealer seamlessly integrates into poultry packaging lines, offering a robust solution for hermetically sealing chicken cut-ups in modified atmosphere packaging (MAP). This equipment stands out for its automated traysealing process, which ensures high hygienic standards crucial for fresh product handling. The TSA models feature sophisticated tray denesting systems and robotized case packing cells, optimizing both speed and efficiency in packaging operations. Capable of continuous, high-speed production, these traysealers adapt to various poultry products, including drumsticks and fillets, enhancing their shelf life and presentation. The system’s automation capabilities enable straightforward integration with existing production lines, ensuring minimal manual intervention and streamlining operational flow. The TSA models are engineered with stainless steel construction, providing durability and resistance to rigorous processing environments. With ULMA Packaging’s commitment to quality and innovation, the traysealers offer configurable options to meet unique production requirements, ensuring maximum productivity and efficiency.

Benefits

- Enhances product freshness with modified atmosphere sealing for extended shelf life.

- Streamlines packaging operations through fully automated traysealing and case packing.

- Minimizes labor costs by reducing manual intervention in the high-speed production line.

- Ensures high hygienic standards crucial for fresh meat packaging.

- Provides durable performance with stainless steel construction suited for rigorous environments.

- Applications

- Chicken cut-ups, Poultry products

- End products

- Chicken breast fillets packaged, Chicken thigh portions sealed in trays, Hermetically sealed chicken cutlet trays, Chicken wings in modified atmosphere packaging, Chicken drumsticks in trays

- Steps before

- Chicken Cutting, Portioning, Tray Preparation

- Steps after

- Carton Boxing, Pallet Stacking, Distribution

- Input ingredients

- chicken cut-ups, empty trays, empty carton boxes

- Output ingredients

- traysealed chicken packages, pallets of carton boxes

- Market info

- ULMA Packaging Spain is renowned for designing and manufacturing innovative, customized packaging solutions for the food, pharmaceutical, and non-food industries, emphasizing advanced automation technology, sustainability, and high-quality service.

- Automation

- Fully automated

- Traysealer model

- TSA models

- Sealing method

- Hermetically sealed in modified atmosphere (MAP)

- Number of packing lines

- Seven

- Case packing cells

- Robotized

- Pallet formation

- Manual

- Tray denester

- Automatic

- Working mechanism

- Fully automated packing lines

- Integrated steps

- Traysealing, Case packing

- Automation level

- PLC/Robotized

- Batch vs. continuous operation

- Inline continuous

- Cleaning method

- Hygienic conditions

- Machine footprint

- Compact, multi-line setup

- Tray configuration

- Hermetically sealed, MAP

- Infeed method

- Automatic tray denester

- Discharge method

- Conveyor belts to distribution system

- Packaging type

- Tray-sealed in MAP

- Carton box system

- Automated transport and distribution

- Robotized case packing

- Mosaic tray formation in boxes

- Control panel type

- PLC-integrated touchscreen

- Automation level

- Fully automated

- Integration possibilities

- Conveyor and robotic integration

- Traysealer model

- TSA models with MAP