Conveying system for small, fragile products

Optimize your production line with high-capacity conveyors designed for efficient handling of small, fragile products, ensuring precise transport with customizable configurations to suit diverse operational needs.

Handles and Transports Small Delicate Products

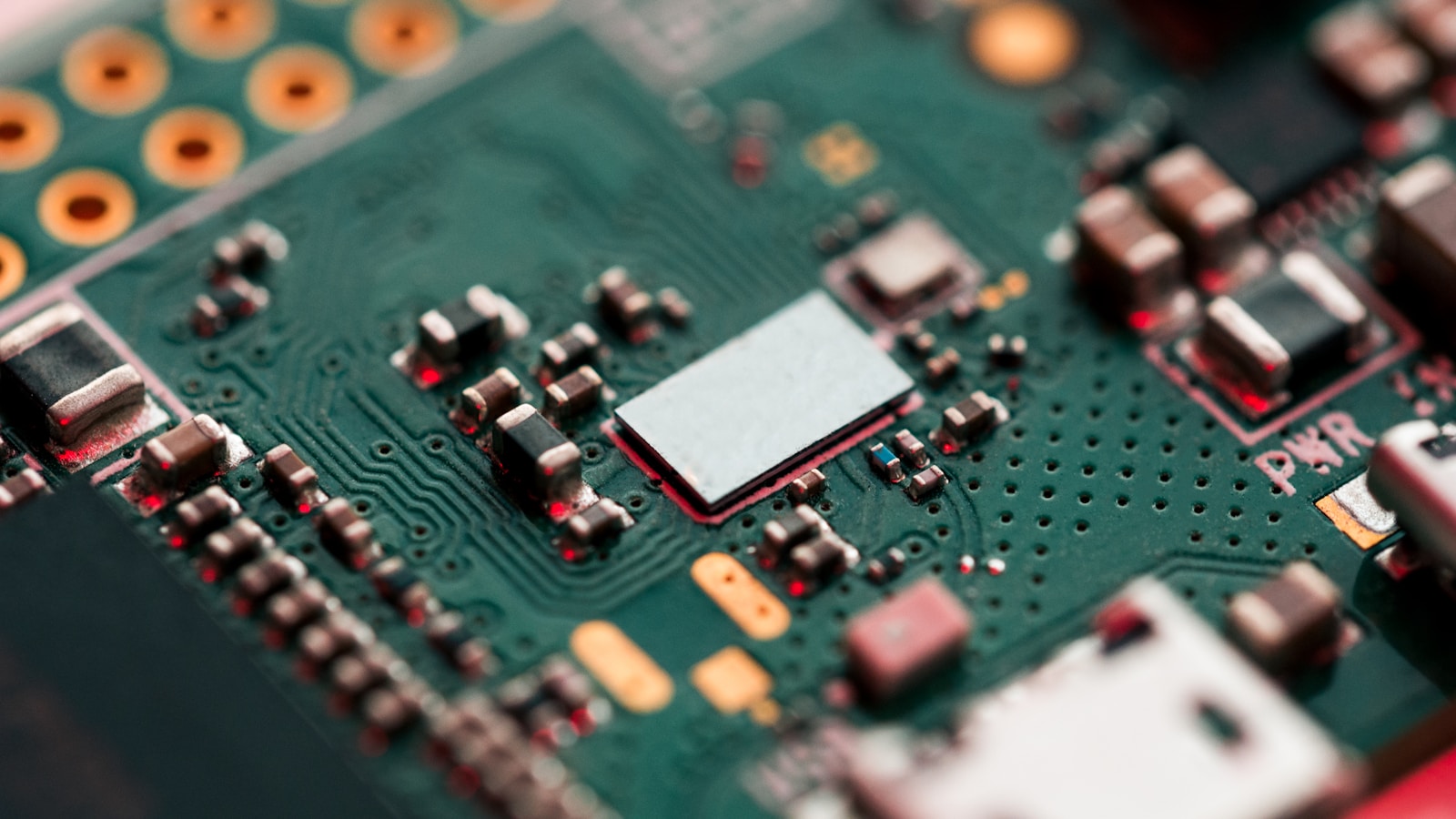

The X45 Puck Handling Conveyor System from FlexLink is engineered for precision and efficiency in managing small, delicate products across various industries, such as electronics, pharmaceuticals, and automotive. It features high-capacity conveying with customizable paths and bends to integrate seamlessly into complex production lines, maintaining continuous operation at high speeds. Equipped with integrated RFID functionality, it allows easy monitoring and quality assurance of transported goods. Utilizing high-efficiency motor technology, it significantly reduces energy consumption compared to conventional systems. This system supports various chain configurations tailored to production requirements, suitable for environments with temperatures ranging from -20 to +60°C. Designed for clean, dry, and ESD-sensitive environments, it excels in transporting items like batteries, medical vials, and circuit boards. The X45 ensures streamlined process flow with fewer interruptions, backed by simple control designs and performance modifications. Available in materials that withstand industrial conditions, it promises long-lasting performance and minimal maintenance.

Benefits

- Enhances efficiency by streamlining high-speed transport and handling of delicate products.

- Substantially lowers energy costs with high-efficiency motor technology.

- Ensures precise tracking and quality control with integrated RFID functionality.

- Adaptable to various production demands with customizable chain configurations.

- Minimizes maintenance and downtime with robust, low-maintenance design.

- Applications

- Automotive, Pharma, Healthcare, Industrial goods, Electronics, Racing

- End products

- Healthcare devices, Circuit boards, Electrical parts, Medical vials, Automotive components, Small bottles, Test tubes, Sensors, Batteries, Racing car parts

- Steps before

- Product Sorting, Quality Inspection, Component Assembly

- Steps after

- Quality Assurance, Labeling, Packaging

- Input ingredients

- small, fragile products, test tubes, small bottles, small packaging, electrical parts, batteries

- Output ingredients

- small, fragile products, test tubes, small bottles, small packaging, electrical parts, batteries

- Market info

- FlexLink (Coesia Group) is renowned for its innovative conveyor and automation systems, optimizing production efficiency for various industries such as food, automotive, and electronics, with a strong emphasis on modular and customizable solutions.

- Max speed

- 20 m/min

- Max product height

- 20 mm

- Min product height

- 20 mm

- Max product width

- 58 mm

- Min product width

- 10 mm

- Operating temperature

- -20 to +60 °C

- Automation

- Integrated RFID functionality

- Energy efficiency

- High-efficiency motor technology

- Chain type

- Plain chain

- Working mechanism

- Puck and Pallet Conveyor System

- Integrated steps

- RFID functionality for process control

- Automation level

- High

- Batch vs. continuous operation

- Inline Continuous

- Energy efficiency

- Lower energy consumption

- Changeover time

- Easy modification of performance

- CIP/SIP

- Not specified

- Cleaning method

- Not specified

- Operating temperature range

- -20 to +60°C

- Max speed

- 20 m/min

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product state

- Clean, dry

- Packaging type

- Test tubes, small bottles, electrical parts (batteries)

- Container shapes

- Asymmetric, rectangular, round, symmetric

- Product type

- Small, fragile products

- Discharge method

- Plain chain

- Control panel type

- Integrated RFID functionality

- Integration Possibilities

- Easy modification of performance with X45 modules

- Modular Design

- High customization with addable bends

- Chain Type

- Configured based on temperature and strength requirements