Twin track pallet conveyors for assembly and testing

Enhance your production line’s efficiency with a system that seamlessly handles diverse product weights and sizes, optimizing assembly and testing processes with precision.

Handles and Positions Products for Assembly and Testing

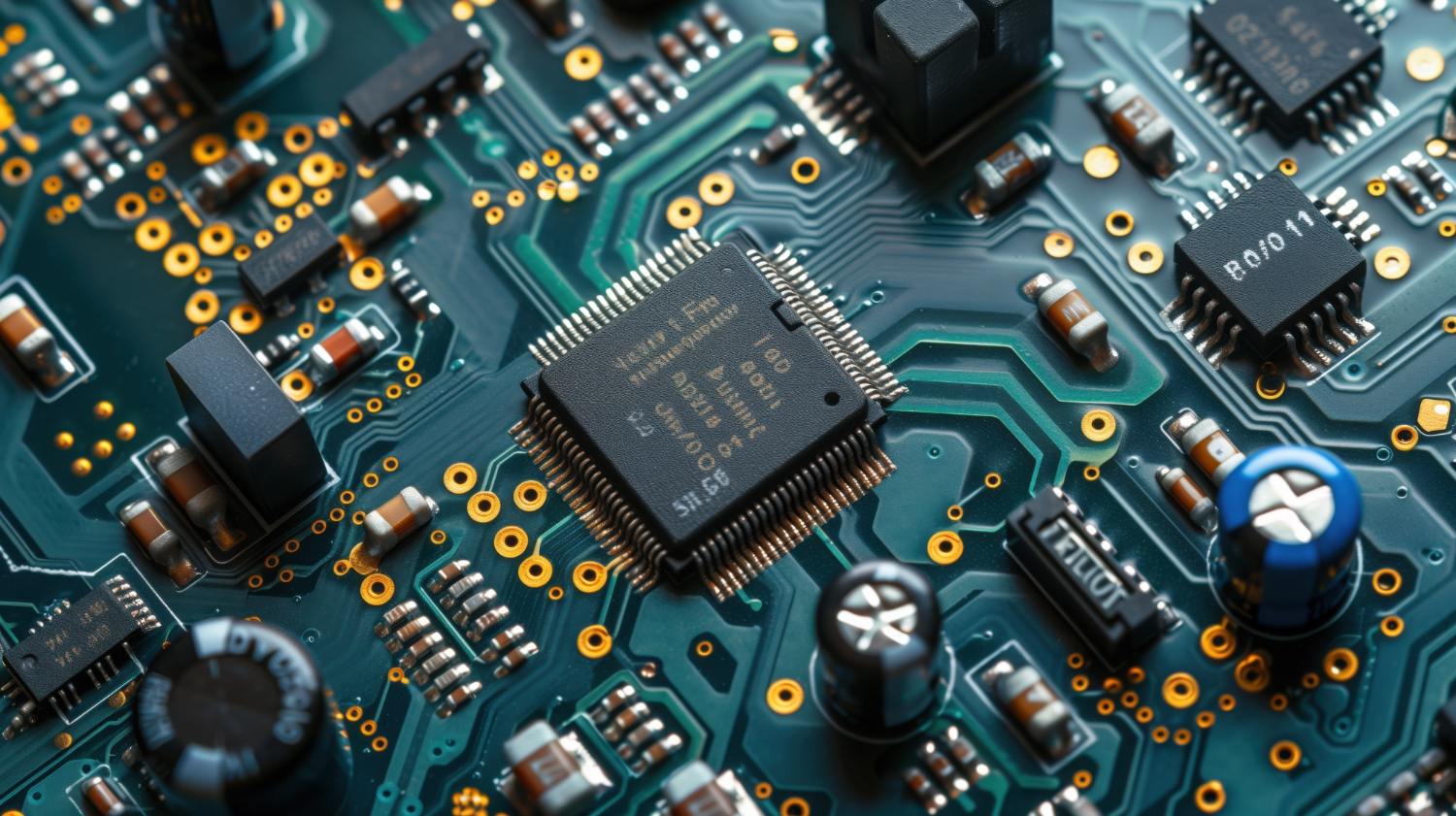

The XT Twin Track Pallet Conveyor System from FlexLink is an engineered solution designed for intricate handling, assembly, and testing requirements in electronics, pharmaceutical, and automotive industries. This system differentiates itself with its ability to accommodate diverse product weights and sizes, using standardized 640 mm width pallets capable of carrying loads from a few grams to 30 kg. The conveyors employ an RFID identification system to ensure precise track-and-trace capabilities, which is crucial for high-stakes applications such as medical device production and automotive sensor manufacturing. Capable of manual or automatic operation, this system achieves up to 20 meters per minute, optimizing productivity. Constructed for versatility, it supports multiple layouts, helping you balance, buffer, and position pallets with ease. Integration is straightforward, with compatibility across various automation systems, facilitated by robust PLC controls. Options for stainless steel material are available, meeting cleanroom standards, while maintenance is streamlined with modular components designed for easy access and replacement.

Benefits

- Enhances operational efficiency with seamless product handling, assembly, and testing.

- Increases production flexibility through configurable and easy-to-rearrange layouts.

- Ensures precise product tracking and quality control with built-in RFID system.

- Reduces maintenance time with modular design and straightforward component access.

- Supports integration with existing line automation for cohesive production management.

- Applications

- Automotive, Pharma, Healthcare, Industrial goods, Electronics, Racing

- End products

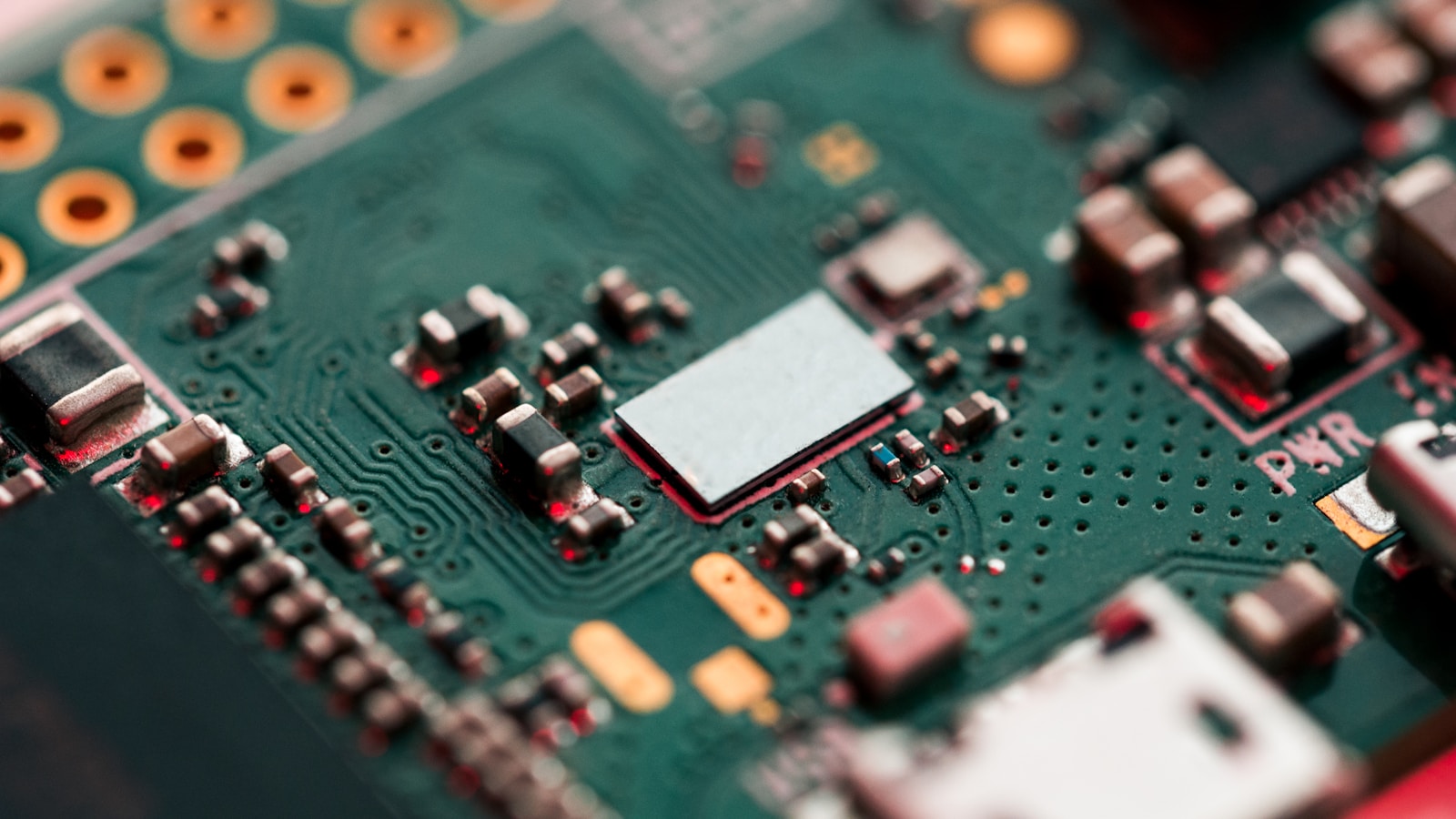

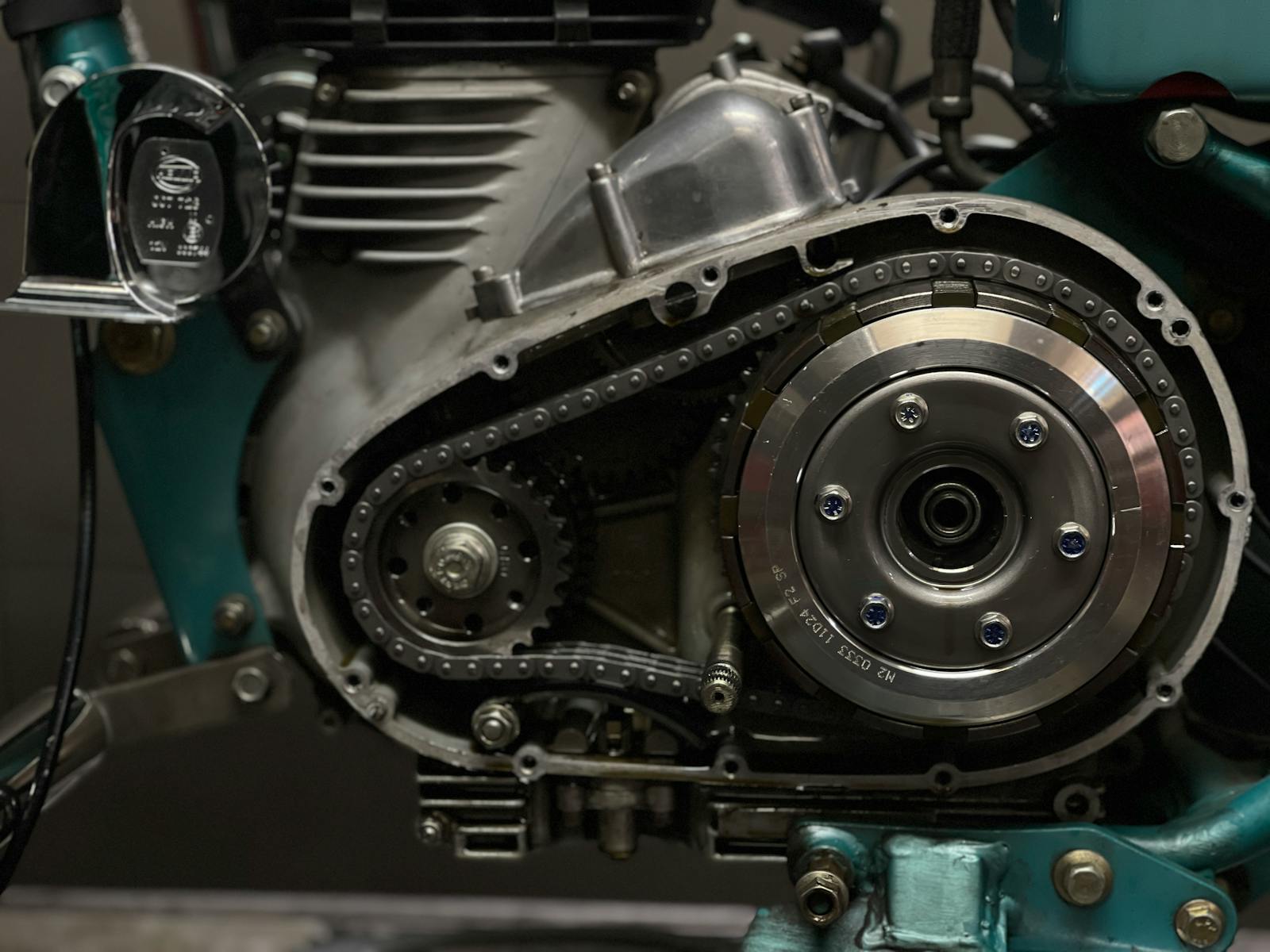

- Circuit boards, Medical devices, Gearboxes, Engine components, Automotive sensors, Racing car parts, Microchips, Surgical instruments

- Steps before

- Assembly, Testing, Product Carriers Preparation

- Steps after

- Balancing, Buffering, Positioning, Track-and-Trace

- Input ingredients

- individual products, product carriers, pallets

- Output ingredients

- assembled products, tested products

- Market info

- FlexLink (Coesia Group) is renowned for its innovative conveyor and automation systems, optimizing production efficiency for various industries such as food, automotive, and electronics, with a strong emphasis on modular and customizable solutions.

- Pallet width

- 640 mm

- Product weight range

- A few grams up to 30 kg

- Operating temperature

- -20 to +60°C

- Max speed

- 20 m/min

- Chain type

- Plain chain

- Pallet dimensions

- 640 mm width

- Weight capacity

- up to 30 kg

- Product state

- Clean, dry

- Operating temperature range

- -20 to +60°C

- Max speed

- 20 m/min

- Automation level

- Manual / Automatic assembly and test systems

- Traceability

- RFID in pallets for track-and-trace

- Configurable modules

- layout for routing, balancing, buffering, and positioning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product size

- Few grams - 30 kg

- Product weight range

- Few grams - 30 kg

- Packaging type

- Asymmetric, Rectangular, Round, Symmetric

- Pallet Width

- 640 mm

- Product Weight Range

- Few grams up to 30 kg

- Machine Footprint

- Configurable Standard Modules

- Discharge Method

- Pallet Routing

- Customization Options

- Configurable Layouts

- Track Width

- Fits products with considerable size/weight

- Control panel type

- HMI compatible

- Integration possibilities

- RFID integration for track-and-trace

- Configurable modules

- Routing, balancing, buffering

- Pallet size

- Customizable up to 640 mm

- Conveyor layout

- Flexible design layouts