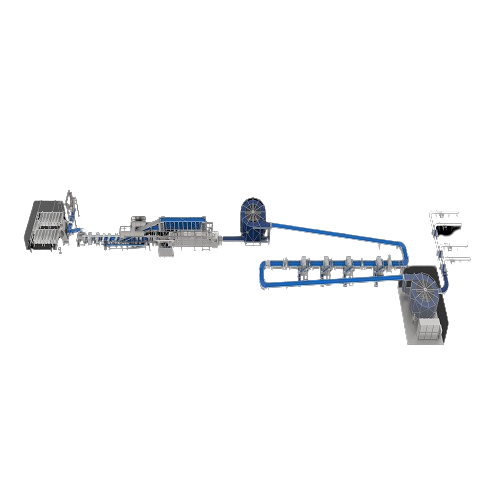

Sheeted pizza and flatbread production system

Achieve seamless integration and high-volume production of diverse baked goods with a system that simplifies sheeting, baking, and decorating of pizzas, flatbreads, and a variety of specialty breads.

Produces and Processes Pizza and Flatbread Dough

The Sheeted Pizza and Flatbread Production System from AMF Bakery Systems is engineered for high-efficiency operations in industrial and commercial bakeries. This fully-automated system streamlines the production of a wide array of baking products, including thin and thick crust pizzas, flatbreads, pita, naan, and tortillas. It achieves up to 80,000 pieces per hour, integrating seamlessly into your production line with its continuous operations. The system encompasses key processes such as mixing, fermentation, sheeting, proofing, baking, cooling, and decorating, all optimized for high-speed performance.

Thanks to sophisticated components like the Tromp SF Sheeting Line and the Den Boer Multibake® Tunnel Oven, it ensures consistent, high-quality output. The system is PLC-controlled, providing real-time data through AMFConnect™ for enhanced decision-making and operational efficiency. With Intralox ThermoDrive® technology, the dough is handled gently, preventing contamination and maintaining product integrity. Options for stainless steel construction ensure durability and ease of cleaning, while its modular design allows for easy customization to fit specific production requirements.

Benefits

- Enhances production capacity with up to 80,000 pieces per hour.

- Minimizes labor costs through fully-automated operations and PLC control.

- Ensures product consistency and quality across diverse baked goods.

- Reduces product waste with precise ingredient application and recirculation system.

- Customizable design allows seamless integration into existing production lines.

- Applications

- Swirl breads, Tortillas, Flatbreads, Pizza snacks, American-style pizzas, Naan, Pita, Sheeted pizzas, Italian-style pizzas

- End products

- Lavash, Greek pita bread, Calzones, Margherita pizza, New york-style pizza, Thin crust pizza, Flour tortillas, Garlic naan, Tandoori naan, Corn tortillas, Cinnamon swirl bread, Detroit-style pizza, Pepperoni pizza, Thick crust pizza, Focaccia

- Steps before

- Dough Mixing, Fermentation, Dough Trough Handling

- Steps after

- Proofing, Baking, Cooling, Freezing, Conveying, Decorating, Packaging

- Input ingredients

- dough, raw dough, cheese, vegetables, proteins

- Output ingredients

- sheeted pizzas, flatbreads, pita, naan, tortilla products, thin crust pizzas, thick crust pizzas, Italian-style pizzas, American-style pizza, pizza snacks

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Production Capacity

- Up to 80, 000 pieces per hour

- Automation

- Fully automated

- Conveyor Capacity

- Up to 30, 000 lbs/hour

- Mixing Capacity

- Up to 3, 200 lbs

- Oven Type

- Tunnel Oven

- Baking Method

- Indirectly heated hot air

- Cooling System

- Spiral Cooler

- Freezing System

- Spiral Freezer

- Sheeting Line Speed

- High-speed

- Working Mechanism

- Sheeting and baking

- Integrated Steps

- Proofing, Baking, Cooling

- Automation Level

- Fully Automated

- Batch vs. Continuous Operation

- Continuous

- Energy Efficiency

- Low kWh/kg

- Throughput

- Up to 80, 000 pieces per hour

- Cleanability

- Yes

- Corrosive resistance

- Yes

- Abrasion resistance

- Yes

- Biological compatibility

- Food-grade

- Baking styles

- Italian-style, American-style