Drying systems for alcohol production

Enhance your spirits production with precise moisture control and nutrient retention, optimizing outputs like whisky and DDGS while ensuring compliance with emission standards.

Dries, Evaporates, and Converts Stillage

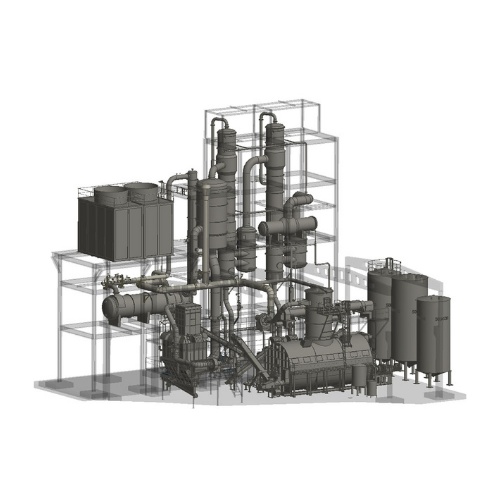

VetterTec’s alcohol production systems excel in transforming distillation by-products into Dry Distillers Grains with Solubles (DDGS) and protein-rich feeds. These systems employ a range of dryers, including tube bundle and spray dryers, coupled with mechanical dewatering and pneumatic conveying systems. Suitable for high-throughput operations, they handle various product types from liquids to solids efficiently. Integrating seamlessly within production lines, the systems leverage advanced automation for continuous operation, ensuring minimal emissions and optimal energy recovery through stillage evaporation. Constructed from robust materials, these systems are designed for durability and corrosion resistance, with options for customization to meet specific production demands. Proven reliable over decades, they are a preferred choice for distilleries and bioethanol producers aiming for efficient waste utilization while complying with environmental standards and feed nutrient requirements.

Benefits

- Enhances production efficiency by transforming by-products into high-value DDGS and protein-rich feeds.

- Reduces operational costs with energy-efficient drying and evaporation processes.

- Minimizes environmental impact with low-emission operations and advanced filtration systems.

- Supports continuous production with robust automation and reliable equipment design.

- Adaptable to various feedstocks and production scales, catering to diverse operational needs.

- Applications

- Ddgs, Bioethanol, Spirits, Alcohol, High protein animal feed

- End products

- Dry distillers grains with solubles (ddgs), Whisky, Protein-rich animal feed, Scotch, Rum, Yeast extract, Ethanol fuel, Brandy, Vodka

- Steps before

- Distillation, Stillage evaporation, Energy recovery

- Steps after

- Drying to DDGS, Feed pelletizing, Yeast spray drying, Pneumatic conveying, Cooling, Intermediate storage

- Input ingredients

- stillage, whisky production materials, vodka production materials, scotch production materials, spirits production materials, syrups

- Output ingredients

- DDGS (Dried Distillers Grains with Solubles), high protein animal feed, pelletized feed, yeast, protein-rich feed, ethanol, whisky, vodka, scotch, spirits

- Market info

- VetterTec is known for engineering and manufacturing industrial drying and dewatering solutions, particularly for the food, brewery, chemical, and environmental industries, leveraging extensive experience in delivering efficient and reliable tailored systems.

- Automation

- High reliability and availability

- Emission Standards

- Latest standards compliance

- Feed Type

- High protein animal feed (DDGS)

- Dryer Type

- Various types including stillage evaporator

- Energy Recovery

- Stillage evaporator

- Emission Control

- Closed Air System, Integrated Filters

- Syrup Utilization

- Highest utilization

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Agglomeration risk

- Low

- Tank shape

- Cylindrical

- Tank size

- Variable

- Discharge method

- Automated

- Control panel type

- Customizable according to user requirements

- Integration possibilities

- Seamless integration with existing distillation systems

- Emission control systems

- Closed Air System with Integrated Filters

- Dryer types

- Various, selected based on specific needs

- Evaporator types

- Stillage Evaporator for energy recovery

- Cooling systems

- Cooling Towers and Meal Cooler options

- Feed systems

- Sophisticated Mixing Systems

- Advanced drying technologies

- High Protein Feed (DDGS) Dryer

- Automation level

- Customizable level of automation