Vacuum packaging for industrial cuts of meat

Enhance production efficiency and packaging integrity with a system designed to automate the vacuum sealing of diverse meat cuts, ensuring a longer shelf life and reduced contamination risk. Ideal for streamlining operations in high-volume settings.

Automates Vacuum Packaging and Sealing

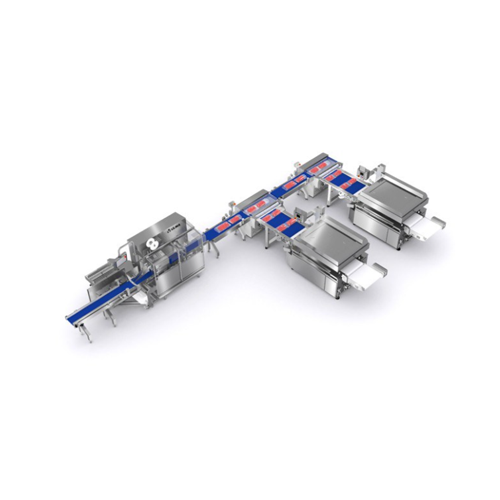

The FLOW-VAC® Vacuum Packaging System with Double Transfer to Chambers from ULMA Packaging offers a revolutionary solution for high-speed meat processing lines. Utilizing a seamless automation process, the FLOW-VAC® creates hermetically sealed vacuum packages, ensuring product freshness and safe storage. The system efficiently handles a variety of meat cuts, including steak, pork chops, and poultry, reducing packaging waste with its innovative film consumption feature. It integrates smoothly with existing vacuum chambers, using an automatic double transfer system that pairs packages for simultaneous sealing, boosting productivity. Catering to the needs of industrial meat processors, it supports continuous, high-speed operations with its robust transfer and sealing mechanisms. The flow-pack design prevents contamination of the sealing area and minimizes vacuum leaks, ensuring high-quality sealed packages. This system is customizable to fit specific production requirements and is engineered for easy maintenance, aligning well with sustainable production goals by lowering material stocks and labor needs.

Benefits

- Increases productivity with automated double transfer system, minimizing manual handling.

- Reduces packaging waste and costs through efficient film usage and sealing.

- Ensures product integrity by minimizing contamination and vacuum leaks.

- Adapts to various meat products, enhancing versatility in production lines.

- Seamlessly integrates with existing vacuum chambers, optimizing operational flow.

- Applications

- Food packaging, Industrial meat cuts, Meat, Poultry

- End products

- Bacon, Lamb shanks, Turkey breast fillets, Pork chops, Chicken breasts, Beef brisket, Steak cuts, Processed ham, Sausage packs, Salami

- Steps before

- Cutting, Trimming, Sorting

- Steps after

- Sealing, Labeling, Storage

- Input ingredients

- industrial cuts of meat, products for vacuum packaging

- Output ingredients

- hermetically sealed packages, vacuum-sealed meat packages, extended shelf life packages

- Market info

- ULMA Packaging Spain is renowned for designing and manufacturing innovative, customized packaging solutions for the food, pharmaceutical, and non-food industries, emphasizing advanced automation technology, sustainability, and high-quality service.

- Automation

- Automatic double transfer system

- Sealing Method

- Flow-Vac® system with hermetic longitudinal and transversal seals

- Film Feeding

- Lower reel, film fed under the product

- Transfer System

- 90° transfer system with buffering belt

- Vacuum Chamber Synchronization

- Integration with multiple manufacturers

- High Productivity

- Capability to load up to two vacuum chambers

- Film Consumption

- Lower film consumption

- Contamination Prevention

- Film fed under the product to avoid sealing contamination

- Sealing Reliability

- High-quality hermetic seals

- Scrap Collection

- Excess film removed and collected

- Working mechanism

- Flow-Vac® system with lower reel machine

- Automation level

- Fully automated with double transfer system

- Integrated steps

- Film feeding, sealing, scrap removal, vacuum chamber loading

- Contamination prevention

- Film under product to avoid contamination

- Batch vs. continuous operation

- Continuous inline operation

- Transfer system

- 90º automatic transfer

- Sealing type

- Longitudinal and transversal hermetic seals

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product Type

- Industrial cuts of meat

- Packaging Method

- Hermetic vacuum sealing

- Product Surface Sensitivity

- Low contamination risk

- Vacuum Chamber Compatibility

- Compatible with various manufacturers

- Discharge method

- 90° transfer system

- Synchronization capability

- Integration with various vacuum chambers

- Integration possibilities

- Integration with various vacuum chambers

- Transfer system type

- 90° transfer system

- Sealing system

- Hermetic seal with high reliability

- Film feeding system

- Lower reel