Continuous pan cleaner for bakery pans

Efficiently clean and prepare baking pans with precision by leveraging continuous, high-speed inversion and multi-stage brush systems for optimal debris removal and improved production workflows.

Cleans and Inverts Bakery Pans Continuously

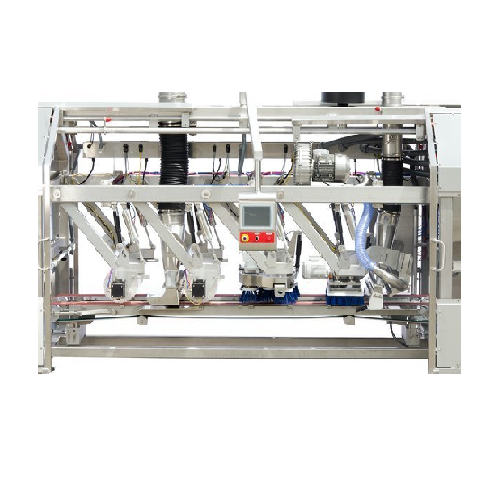

The FME Continuous Pan Cleaner from Shaffer Mixers & Processing Equipment is designed for high-speed cleaning and inversion of bakery pans, addressing the specific needs of industrial bakeries and food processing companies. This equipment utilizes a continuous, inverting conveyor system to move pans through a multi-stage cleaning process, optimizing waste removal without inverting during operation. Its open access design with swing arm-mounted cleaning heads allows for easy maintenance and sanitation.

Applications include the removal of protein washes and seed toppings from a variety of bakery products, such as loaves of bread, croissants, muffin tins, and more. Capable of cleaning over 50 pans per minute, the cleaner is suitable for high-speed, continuous operations. It offers customizable cleaning heads, including roller, orbital, rotary brushes, and air knives for comprehensive debris removal.

The pan cleaner is equipped with operator interface controls for programmable head position, speed, and pressure settings, ensuring precise operation. Compliance with UL and CUL standards guarantees safety and reliability in food-grade environments. Optional features like duplicate cleaning heads and additional cleaning heads are available for enhanced allergen management and maintenance. Constructed from durable materials, it includes a NEMA 4X stainless steel electrical enclosure for robust industrial use.

Benefits

- Maximizes operational efficiency by cleaning over 50 pans per minute.

- Minimizes downtime with quick-change brushes, enabling seamless product transitions.

- Ensures thorough cleaning with interchangeable multi-stage cleaning heads.

- Enhances production flexibility with adaptable pan entry options and orientations.

- Supports stringent hygiene standards with easy-to-maintain open access design.

- Applications

- Pans, Muffins, Protein washes, Breads, Seed toppings, Pastries, Bakery products

- End products

- Focaccia pans, Muffin tins, Brioche rolls, Sourdough bread loaves, Croissants, Pie crusts, Loaves of bread, Baguette pans, Dinner rolls

- Steps before

- Baking, Dough Formation, Proofing

- Steps after

- Packing, Stacking, Distribution

- Input ingredients

- pans, protein washes, seeds, loose toppings

- Output ingredients

- clean pans, removed debris, collected waste

- Market info

- Shaffer is known for designing and manufacturing industrial mixing equipment, primarily for the baking industry, including dough mixers and processing systems. They are recognized for their expertise in creating customized solutions that enhance efficiency and meet specific customer needs.

- Speed

- 50 or more pans per minute

- Cleaning method

- Continuous, multi-stage

- Automation

- Programmable operator controls

- Brush change time

- Seconds

- Pans orientation

- Upright or inverted

- Pan flow direction

- Left or right-hand side

- Elevation

- Low or high

- Compliance

- UL, CUL

- Pressure settings

- Adjustable

- Material

- NEMA 4X stainless steel

- Automation level

- PLC

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual / Quick-Change Brushes

- Energy efficiency

- High-speed operation

- Pan orientation flexibility

- Upright / Inverted

- Changeover time

- Brushes change in seconds

- Cleaning head options

- Roller, orbital, rotary brush, air knife

- Automation level

- Controls for head position, speed, pressure

- Pan flow direction

- Left or Right-hand side

- Waste collection

- Integrated collection bin

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- NEMA 4X Stainless Steel Electrical Enclosure

- Discharge method

- Infeed and Discharge can be low or high elevation

- Belt type

- Continuous Inverting Conveyor

- Brush type

- Roller brush, orbital brush, rotary brush, air knife

- Control panel type

- Operator interface controls

- Brush type

- Roller, orbital, rotary

- Pan entry orientation

- Left or right-hand side

- Elevation options

- Low or high elevation

- Additional cleaning heads

- Available

- Brush change over time

- Less than 30 seconds

- Waste collection system

- Debris collection bin

- Electrical enclosure type

- NEMA 4X Stainless Steel