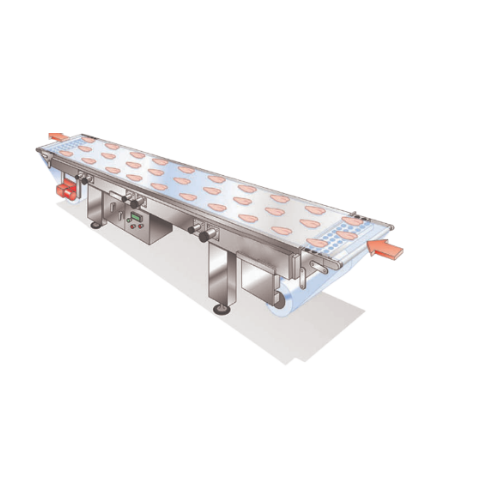

Crust freezer for delicate and sticky products

For processors handling delicate and sticky items, ensuring product stability and appearance before full freezing is crucial to streamline handling and reduce losses. This technology crust-freezes product undersides, enhancing line efficiency and product yield.

Stabilizes and Crust-Freezes Delicate Food Products

The Frigoscandia SuperCONTACT® Crust Freezer from JBT is designed to meet the needs of bakery and meat processors facing challenges with handling delicate or sticky products. This equipment uses a refrigeration-based contact freezing method, where products are conveyed on a polyethylene film over a refrigerated plate, creating a stabilizing crust on the bottom. This prevents deformation, sticking, and belt marks, allowing for smooth transition to a conventional freezer belt. Ideal for pastries, meat cuts, and plant-based proteins, it supports continuous high-speed operations with minimal drip loss, enhancing line capacity. The equipment is available with stainless steel framing and offers various belt widths and lengths to suit different production demands. Designed for hygiene, it uses disposable film to maintain cleanliness, and integrates easily into existing freezing processes.

Benefits

- Enhances product quality by preserving shape and appearance, eliminating sticking and deformation.

- Increases overall line capacity through reduced dwell time in the final freezing stage.

- Maintains stringent hygiene standards with disposable polyethylene film.

- Minimizes product weight loss and rejects by sealing moisture and reducing drip loss.

- Decreases operational costs with improved energy efficiency and reduced waste.

- Applications

- Seafood, Ready meals, Bakery, Meat, Confectionery, Plant-based protein, Poultry

- End products

- Chocolate truffles, Frozen dinner lasagna, Salmon fillets, Chicken breasts, Pre-packaged beef stew, Bread loaves, Shrimp, Turkey slices, Steak cuts, Cakes, Pastries, Tofu blocks, Veggie patties

- Steps before

- Grinding, Mixing, Forming, Injection, Portioning, Slicing

- Steps after

- Full Freezing, Final Freezing, Packing, Weighing, Bagging

- Input ingredients

- delicate products, wet products, shape-sensitive products, sticky products, protein items, bakery items

- Output ingredients

- stabilized frozen crust products, products with minimal drip loss, shape-maintained products, hygienic products

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Usable belt width

- 36 in., 42 in., 72 in.

- Module length

- 10 ft., 14 ft.

- Material frame

- Stainless steel

- Freezing type

- Mechanical refrigeration

- Film material

- Polyethylene

- Depth of frozen crust

- 1 millimeter

- Capacity requirements

- Multiple widths and lengths

- Energy efficiency

- Increased line capacity

- Working Mechanism

- Mechanical Refrigeration Freezing

- Integrated Steps

- Crust Freezing as Pre-Freeze Step

- Hygiene Methodology

- Polyethylene Film Contact

- Product Handling Efficiency

- Minimal Drip Loss

- Batch vs. Continuous Operation

- Continuous

- Switch Over Method

- Polyethylene Film to Freezer Belt

- Speed

- Increased Line Capacity

- Yield Improvement

- 0% Drip Loss

- Corrosive resistance (e.g. acids)

- Stainless steel

- Density/particle size

- Varied for delicate, wet, sticky products

- Shape sensitivity

- High, Medium, Low

- Temperature sensitivity

- Yes/No

- Machine footprint

- Varies by model, multiple widths and lengths available

- Belt widths

- 36 in., 42 in., 72 in.

- Module lengths

- 10 ft., 14 ft.

- Frame material

- Stainless steel

- Feed/discharge method

- Conveyor belt

- Film material

- Polyethylene

- Usable belt widths

- 36 in., 42 in., 72 in.

- Module lengths

- 10 ft., 14 ft.

- Frame Material

- Stainless steel