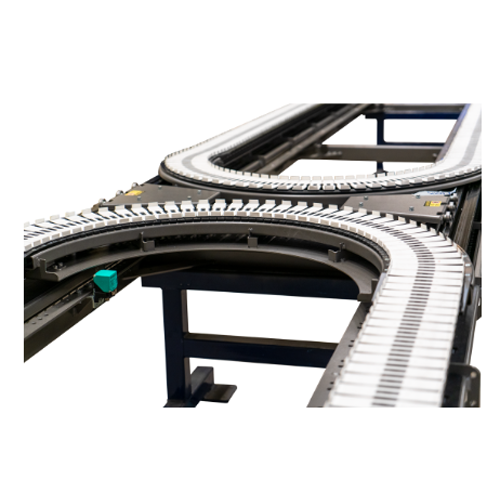

Dynamic accumulation conveyor for packaging and bottling

Optimize your production flow with a conveyor system designed to absorb and release items dynamically, ensuring seamless operation without interruptions. Perfect for high-speed environments where space-saving and efficiency are critical.

Accumulates and Conveys Solid Products Efficiently

The AccuVeyor AVL-Series from AmbaFlex is a versatile dynamic accumulator and conveyor system designed to address common production challenges in industries like logistics, packaging, and bottling. This equipment utilizes a unique trombone-like mechanism, allowing seamless absorption and release of products such as small cereal boxes, bottled drinks, and e-commerce parcels, without interrupting continuous operations. With a load range of up to 15 kg/m and an adjustable belt width spanning 100 to 600 mm, it proficiently manages high-speed applications by accommodating varying product sizes and types. The system’s single-belt, non-touching accumulation mechanism minimizes wear and maintenance needs, while its durable conveyor frame is constructed to meet demanding operational conditions. Integration is straightforward, with options for automation and real-time monitoring to ensure smooth workflow across upstream and downstream processes. Whether handling bulk shampoo bottles in bottling plants or promotional flyers in the print industry, the AccuVeyor AVL-Series boosts both efficiency and throughput, providing a reliable solution to dynamic accumulation requirements.

Benefits

- Enhances production efficiency with continuous dynamic accumulation.

- Accommodates diverse product types, reducing equipment changeover times.

- Minimizes maintenance costs with a non-contact belt system.

- Streamlines integration into existing production lines with flexible configuration.

- Supports high-speed operations to meet demanding throughput requirements.

- Applications

- Packaging, Print, Bottling, Logistics

- End products

- Promotional flyers, Perfume packages, E-commerce parcels, Bottled water, Soda bottles, Yogurt cups, Small cereal boxes, Instant noodle packs, Shampoo bottles, Canned goods

- Steps before

- Sorting, Filling

- Steps after

- Packing, Sealing, Labeling

- Input ingredients

- small cartons, pouches, sealed cups, flow packs, cups, jars, trays

- Output ingredients

- small cartons, pouches, sealed cups, flow packs, cups, jars, trays

- Market info

- AmbaFlex is renowned for its expertise in manufacturing innovative spiral conveyor solutions, specializing in dynamic material handling systems across various industries, enhancing efficiency and operational flow with customizable, space-saving designs.

- Belt width range

- 100, 140, 400, 600 mm | 4, 5.5, 16, 24"

- Speed range

- up to 42 m/min | 138 fpm

- Load range

- up to 15 kg/m | 10.2 lb/ft

- Accumulation length

- 40 m | 131 ft

- Multi-belts system

- patented ONE-belt non-touching accumulation system

- Working mechanism

- U-shaped dynamic accumulation

- Automation level

- PLC controlled

- Changeover time

- Rapid adjustment

- Batch vs. continuous operation

- Continuous dynamic accumulation

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Goods type

- Cartons, pouches, cups, jars, trays

- Container size

- Small

- Transportation type

- Flow packs

- Compatible load

- Up to 15 kg/m | 10.2 lb/ft

- Conveyor type

- U-shaped dynamic accumulator

- Belt width

- 100, 140, 400, 600 mm | 4, 5.5, 16, 24"

- Frame width

- 100 mm / 4"±800 mm / 2' - 8"

- Load capacity

- up to 15 kg/m | 10.2 lb/ft

- Accumulation length

- 40 m | 131 ft

- System configuration

- ONE flexible conveyor belt with non-touching accumulation

- Speed range

- up to 42 m/min | 138 fpm

- Conveyor segment configuration

- U-shaped

- Belt width options

- 100, 140, 400, 600 mm

- Frame width options

- 800 mm to 2240 mm

- Load range

- up to 15 kg/m

- Speed range

- up to 42 m/min

- Accumulation length

- 40 m

- Material handling suitability

- small cartons, pouches, sealed cups, flow packs, cups, jars, trays