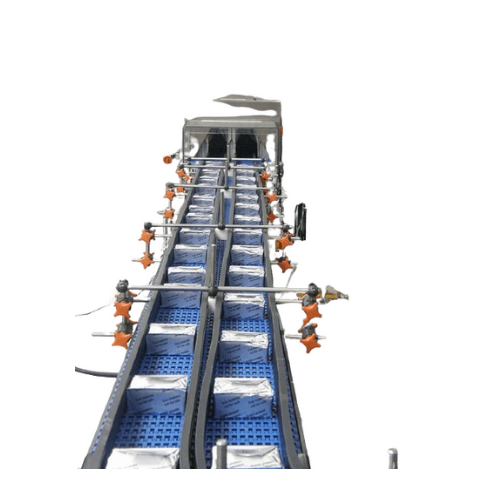

Industrial conveyor system for food and pharma applications

Optimize your production workflow with a versatile conveyor system that seamlessly handles complex transport needs, from vertical and diagonal moves to continuous, variable speed operations, ensuring efficient material and product flow with minimal maintenance.

Transports and Elevates Solid Products

The 750 SERIES Slat Belt Conveyor System from TREPKO is expertly engineered for a wide range of applications in the food, technochemical, and pharmaceutical industries. This system features a modular design combining drive units, straights, curves, elevations, and guide rails for versatile adaptation to various production line configurations. Operating with a continuous variable-speed system, it seamlessly integrates into existing processes, facilitating the efficient transport and elevation of solid products such as canned soups, yogurt cups, and detergent containers. Capable of operating across temperatures from -20°C to +100°C, it ensures reliable performance under challenging conditions. The conveyor’s robust construction emphasizes high efficiency and durability, requiring minimal maintenance for long-term operational reliability. With configurable lengths based on product weight and curve requirements, the 750 SERIES supports customized solutions to meet specific production needs.

Benefits

- Enhances production flexibility with modular components tailored to specific layout requirements.

- Improves operational efficiency through continuous, variable-speed transport.

- Minimizes maintenance needs, ensuring long-term reliability in rigorous industrial settings.

- Adapts to harsh environments with temperature tolerance up to +100°C.

- Supports diverse product handling, from lightweight pharmaceutical packs to heavier food containers.

- Applications

- Food, Pharmaceutical products, Technochemical

- End products

- Canned soups, Pill bottles, Cream tubes, Blister packs, Yogurt cups, Ready-to-eat meals, Packaged supplements, Shampoo bottles, Detergent containers

- Steps before

- Sorting, Cleaning

- Steps after

- Packaging, Quality Control

- Input ingredients

- light weight product, food industry items, technochemical products, pharmaceutical items

- Output ingredients

- transported products, organized items, sorted materials

- Market info

- Speed

- 2-45 m/min

- Product Width Range

- 25-300 mm

- Max Product Weight

- 20 kg

- Total Product Weight per Conveyor

- 150 kg

- Operation Temperature Range

- -20°C to +60°C, up to +100°C temporarily

- Transport Direction

- Vertical / Horizontal / Diagonal

- Speed Adjustment

- Variable Speed

- Modularity

- Modular System

- Maintenance Requirement

- Easy Maintenance

- Production Condition Adaptability

- Adapts to Different Production Conditions

- Environmental Temperature Range

- -20°C to +60°C, up to +100°C temporarily

- Product Weight Capacity

- Max 20 kg per product, Total 150 kg per conveyor

- Length Determination

- Based on Product Weight and Number of Curves

- Temperature resistance

- -20°C to +60°C continuous, up to +100°C temporarily

- Corrosion resistance

- Suitability for food, technochemical, and pharmaceutical industries

- Load bearing capacity

- Max. product weight 20 kg, total product weight per conveyor 150 kg

- Wear resistance

- High efficiency and durability in tough environments

- Transport orientation

- Vertical / Horizontal / Diagonal

- Industry suitability

- Food / Technochemical / Pharmaceutical

- Product weight per conveyor

- 150 kg total

- Conveyor System Length

- Determined by product weight and the number of curves

- Conveyor System Configuration

- Vertical, Horizontal, Diagonal

- Modular Components

- Drive units, straights, curves, elevations, legs, guide rails

- Temperature Range

- -20°C to +60°C during continuous operation, up to +100°C temporarily

- Variable Speed Control

- 2-45 m/min

- Modular Design

- Drive units, straights, curves, elevations, legs, guide rails

- Transport Modes

- Vertical, horizontal, diagonal

- Construction Material

- Developed for high durability in tough environments