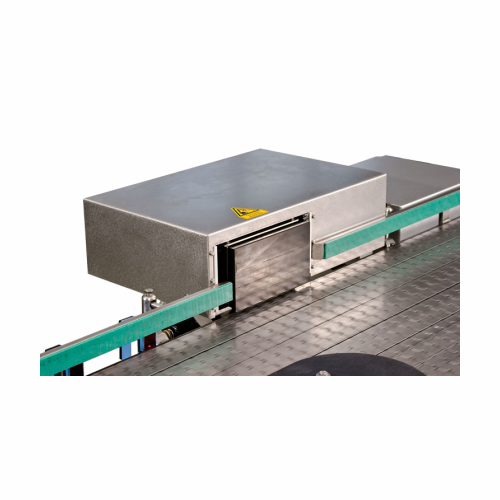

Precision case rejector for faulty packaging

Ensure seamless production flow by reliably removing defective packaging with precision rejector technology, improving operational efficiency without the need for complex changeovers.

Rejects and Distributes Faulty Cases Efficiently

The HEUFT case rejector is an engineered solution from HEUFT SYSTEMTECHNIK GMBH designed to enhance the efficiency of packaging operations across beverage, food, and pharmaceutical production lines. Leveraging a load-dependent control system, this equipment adapts the rejection impact to varying case weights, ensuring precise removal of non-brand or defective packages. Uniquely capable of integrating into high-speed, continuous production processes, the HEUFT case rejector excels in handling a wide array of end-products, from soda bottles and milk cartons to pharma blister packs and cosmetic boxes, ensuring brand integrity by removing faulty units without disrupting line flow. Supporting capacity adjustments and smoother operations, its mechanical simplicity negates the need for complex case changeovers. Additionally, the modular design facilitates easy integration with existing conveyor systems, providing options for multi-lane distribution and contributing to optimized packaging efficiency.

Benefits

- Maintains production efficiency by seamlessly rejecting defective packages without halting operations.

- Minimizes product waste with precise, load-dependent ejection of various weight cases.

- Enhances packaging line flexibility by supporting multi-lane distribution and diverse product types.

- Reduces operational complexity and setup time with a no-changeover-required design.

- Enhances product safety and quality control by ensuring only compliant packages continue in the production line.

- Applications

- Food, Pharma, Beverage, Packaging

- End products

- Canned goods boxes, Pet food packages, Medicine bottles, Juice cartons, Pharma blister packs, Soda bottles, Nutritional supplement containers, Liquid detergent containers, Beer crates, Wine boxes, Cosmetic product boxes, Cereal boxes, Snack trays, Milk bottles, Frozen food packages

- Steps before

- Filling, Bottling, Packaging

- Steps after

- Inspection, Labelling, Packing

- Input ingredients

- faulty bottle crates, damaged trays, faulty trays, empty cases, half-full cases, full cases, crates of varying weights

- Output ingredients

- parallel conveyor chains, distributed onto several lanes, rejected equal distance, non-brand crates, removed faulty packages

- Market info

- HEUFT is known for its expertise in inline quality inspection systems and automation solutions for the food, beverage, and pharmaceutical industries, with a reputation for innovation and reliability in ensuring product safety and integrity.

- Rejection Method

- Load-dependent control

- Rejection Distance

- Equal distance for crates of varying weights

- Rejection Fingers

- 3 rejection fingers on a sledge

- Rejection Segment Activation

- Time adjusted based on crate weight

- Load-Dependent Control

- Adapts to weight of individual case

- Space-Saving Design

- Compact system installed above conveyor

- Load-dependent control system

- Automatic force adaptation

- Rejection Method

- Tray or case rejection

- Multi-lane distribution

- Possible with multiple rejectors

- Distance Consistency

- Equal rejection distance for varying weights

- Space-saving Design

- Compact system above conveyor

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Case type

- Crates / Cardboard boxes / Trays / Shrink wrap packages

- Container weight

- Varying weights

- Compact footprint

- Space-saving, installed above the conveyor

- Control panel type

- Load-dependent control system

- Discharge method

- Rejection fingers on sledge and rejection impact

- Control panel type

- Load-dependent control system

- Integration possibilities

- Multiple rejection systems in series

- Space-saving design

- Compact system (HEUFTmaxi-laner)

- Rejection method

- Load-dependent impact force adaptation

- Lane distribution

- Multilane distribution capability