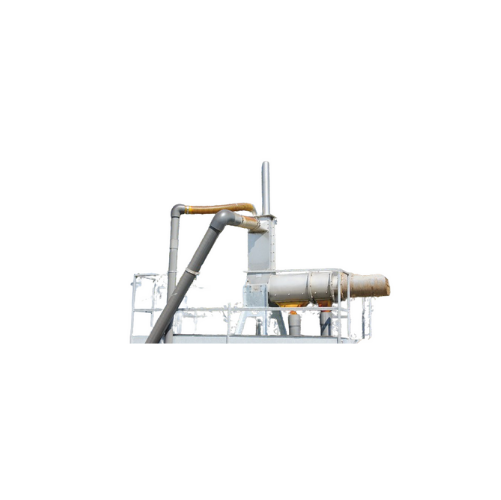

Horizontal screw press separator for manure treatment

Enhance your separation processes with advanced screw press technology, optimizing liquid-solid management across diverse waste types, from manure to industrial wastewater, reducing environmental impact and improving operational efficiency.

Separates Liquids and Solids in Diverse Slurries

The SEPCOM Horizontal Screw Press Separator from WAMGROUP is designed for efficient liquid-solid separation across multiple industries, including agriculture, biogas, and wastewater treatment. Engineered to handle diverse slurries, this separator operates through a screw conveyor system combining gravity and mechanical compression to achieve optimal separation. It features a modular screw made from anti-wear SINT engineering polymer and a self-cleaning screen basket that ensures durability and reduced wear. Capable of continuous automatic operation, the SEPCOM efficiently processes applications like manure treatment, vegetable and fruit waste processing, and sludge management. It produces high-quality end-products such as biogas digestate fertilizers, dewatered sludge cakes, and animal feed supplements. With options for various diaphragm outlets and screen basket sizes, it’s adaptable to specific processing needs. The SEPCOM delivers significant cost reductions in solids-liquid management and fast maintenance due to its straightforward assembly.

Benefits

- Optimizes resource use by effectively separating liquid and solid phases.

- Minimizes maintenance efforts with a durable, self-cleaning design.

- Lowers operating costs through reduced wear and cost-effective spare parts.

- Increases processing efficiency for diverse materials, from manure to industrial sludge.

- Enhances environmental compliance by facilitating high-quality waste recycling.

- Applications

- Organic household waste, Vegetable waste processing, Sludge treatment, Fruit waste processing, Biogas plant equipment, Livestock manure treatment, Agricultural by-products, Pulp, Municipal wastewater treatment, Paper processing, Industrial wastewater treatment, Starch by-products processing, Livestock by-products

- End products

- Animal feed supplements from agricultural by-products, Dewatered sludge cake, Cellulose pulp, Animal feed supplements from livestock by-products, Fruit compost, Treated municipal sludge, Biogas digestate fertilizer, Vegetable compost, Compost from organic household waste, Recycled paper fiber, Compost from livestock manure, Starch-based animal feed supplements, Recycled industrial water

- Steps before

- Grinding, Emulsification, Blending, Mixing, Pre-treatment

- Steps after

- Drying, Waste Disposal, Packing, Liquid Disposal, Composting

- Input ingredients

- sludge, sewage, manure, vegetable processing waste, fruit processing waste, solids-liquid mixtures, biogas plant materials, industrial process materials, slurry from livestock breeding

- Output ingredients

- separated solid phase, separated liquid phase, high solids content in solid phase, digestate from anaerobic digester

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Abrasiveness of material

- Yes/No

- Capacity

- Variety of materials

- Automation

- Automatic operation

- Material Compatibility

- Biogas, Industrial Processes, Livestock Slurry

- Screw Design

- SINT engineering polymer

- Screen Type

- Self-cleaning screen

- Separation Method

- Gravity and mechanical compression

- Durability

- Wear-resistant

- Screw Type

- Modular screw

- Phase Separation

- Solids-liquid

- Drive Unit

- Electric motor with gear reducer

- Screen Basket

- Cylindrical

- Counter-Pressure Diaphragm

- Self-adjusting

- Batch vs. continuous operation

- Continuous

- Automation level

- Automatic operation

- Cleaning method

- Self-cleaning

- Energy efficiency

- High separation efficiency

- Material adaptability

- Multiple material compatibility

- Mechanical separation

- Screw press technology

- Wear resistance

- High wear-resistant screen basket

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design

- Basket type

- Cylindrical screen basket

- Discharge method

- Counter-pressure diaphragm outlet

- Screw type

- SINT engineering polymer screw

- Hopper design

- Compensator hopper tank

- Diaphragm outlet types

- Various types available

- Polymer screw types

- SINT engineering polymer screws

- Screen basket sizes

- Various sizes available