Grain unloading conveyor for ground level use

Efficiently unload bulk materials at ground level while minimizing dust and ensuring optimal flow, perfect for high-capacity operations needing space-saving solutions.

Transports and Unloads Bulk Materials Continuously

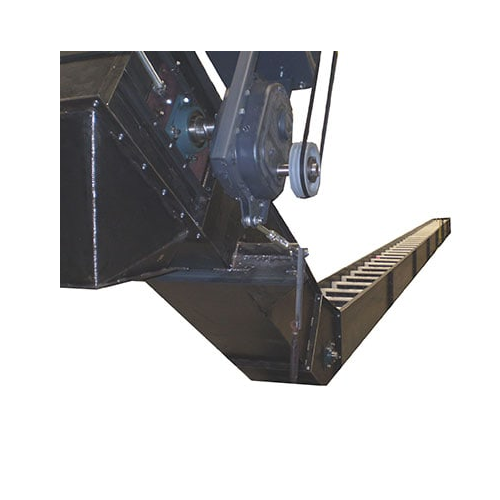

The Pit Eliminator Drag Conveyor from Scott Equipment Company is specially engineered for facilities aiming to optimize bulk material unloading and transport while minimizing dust-related issues. This conveyor system boasts a flat-bottom design, which provides greater capacity in a compact vertical profile, making it ideal for animal nutrition, pet food, ethanol, and various industrial applications. Capable of moving up to 18,000 cubic feet per hour, the Pit Eliminator ensures efficient, continuous operation.

The conveyor’s square construction includes 55-degree side slopes and a dust-tight take-up section that employs 1/4″ thick rubber gaskets with positive eccentric cams for effective dust containment. For non-free-flowing materials, the optional Double Sprocket tail elevates the chain return shroud to prevent blockage, ensuring a continuous material flow. Designed for integration within both pre-processing and transport departments, it handles solid and granular products with ease and maintains a dust-free environment.

This system is equipped for seamless integration into your production line, featuring manual operational options that prioritize maintenance ease. While Scott Equipment offers standard replacement parts to facilitate quick repairs, the custom-built approach of the Pit Eliminator emphasizes quality fabrication to meet specific production needs.

Benefits

- Enhances operational efficiency by unloading and conveying bulk materials rapidly at ground level.

- Minimizes maintenance disruptions with dust-tight components that contain particles effectively.

- Reduces the risk of material blockages with an innovative design that handles non-free-flowing products.

- Customizable layout to fit specific facility requirements, optimizing spatial use.

- Facilitates seamless integration into existing production lines, reducing installation complexities.

- Applications

- Animal feed, Ethanol, Pet food, Grain, Industrial applications

- End products

- Steps before

- Loading, Material Handling

- Steps after

- Material Unloading, Storage

- Input ingredients

- grain, animal nutrition materials, pet food ingredients

- Output ingredients

- unloaded grain, processed animal nutrition components, processed pet food

- Market info

- Scott Equipment is known for its expertise in custom-designed industrial mixing and processing equipment, catering to diverse industries with a strong reputation for quality, innovation, and customer-focused engineered-to-order solutions.

- Capacity

- Up to 18, 000 cubic ft/hr

- Side Slope Angle

- 55 degrees

- Construction Thickness

- 1/4" rubber gaskets

- Design Type

- Flat bottom conveyor

- Working mechanism

- Flat bottom drag conveyor

- Integrated steps

- Chain return with double sprocket tail

- Batch vs. continuous operation

- Continuous

- Dust containment

- Dust tight take-up with rubber gaskets

- Positive clean-out

- Flat bottom with true radius

- Capacity

- Up to 18, 000 cubic ft/hr

- Automation level

- Custom built

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Ideal for grain unloading

- Yes

- Conveyor shape

- Square construction, flat bottom

- Side slopes angle

- 55-degree

- Discharge method

- Ground level unloading

- Chain return clearance

- Increased by Double Sprocket tail option

- Chain return shroud height

- Adjustable with Double Sprocket tail option

- Flat bottom design

- For greater capacity with less height

- Take-up section

- Dust tight with rubber gaskets

- Curved and tail section radius

- True radius for positive clean-out