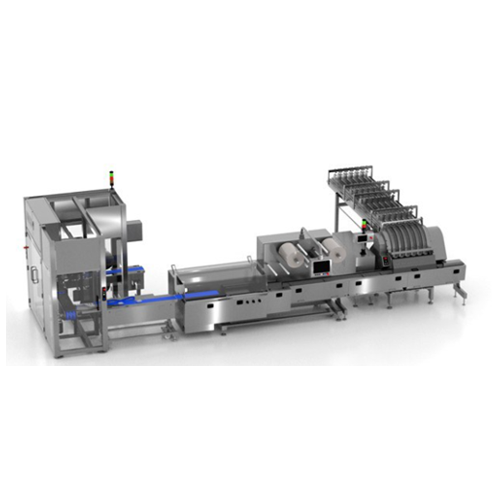

Sustainable biscuit packaging line

Enhance your biscuit production with a fully automated packaging line that leverages sustainable materials, efficiently handling products to minimize waste and environmental impact.

Efficiently Wraps and Labels Biscuits and Bakery Products

The sustainable biscuit packaging line featuring the Biscuit Pile Loader, Horizontal FR 400 Flow Wrapper, and Multipack Labeller from ULMA Packaging revolutionizes your production process. This line is engineered for efficient operations with a fully automated system that streamlines stacking, wrapping, and labeling of biscuits and other bakery products. The FR 400 Flow Wrapper stands out for its ability to produce up to 70 linear meters of packaging film per minute, utilizing recyclable 100% paper film to meet eco-friendly standards. It integrates seamlessly with digital controls and remote management, offering flexibility and high-speed throughput for continuous production. Particularly suitable for food manufacturers and sustainable packaging companies, this system reduces material waste with innovative packaging solutions like adhesive paper labels for multipacks, which replace traditional secondary packaging. Designed for reliability and consistency, this equipment supports a wide range of applications—from digestive biscuits to macarons—and operates under rigorous conditions while minimizing product damage. ULMA Packaging provides engineering support and customization options to match specific production needs, ensuring your line meets industry requirements.

Benefits

- Increases production efficiency with high-speed, fully automated packaging operations.

- Reduces material costs by using 100% recyclable paper for sustainable packaging.

- Minimizes product damage through precise handling and control throughout the process.

- Enhances flexibility with adjustable stacking parameters to accommodate various biscuit types.

- Supports remote management and monitoring for streamlined supply chain integration.

- Applications

- Bakery products, Biscuits, Confectionery, Snacks

- End products

- Digestive biscuits, Chocolate chip cookies, Cream-filled sandwich cookies, Ginger snaps, Vegan oat bars, Shortbread cookies, Macarons, Biscotti, Multi-grain crackers, Savory cheese biscuits

- Steps before

- Biscuit stacking, Biscuit sorting

- Steps after

- Product grouping, Labelling, Multipack formation

- Input ingredients

- biscuits, recyclable paper, adhesive paper labels

- Output ingredients

- stacked biscuits, primary packaging, multipack packaging, rejected packages

- Market info

- ULMA Packaging Spain is renowned for designing and manufacturing innovative, customized packaging solutions for the food, pharmaceutical, and non-food industries, emphasizing advanced automation technology, sustainability, and high-quality service.

- Automation

- Fully automated solution

- Primary packaging material

- 100% recyclable paper

- Multipack packaging material

- 100% recyclable paper with adhesive labels

- Production speed

- 70 linear metres/minute

- Pile formation flexibility

- 4 to 10 biscuits

- Rejection System

- Sensor-based rejection of invalid packages

- Multipack group size

- 5 units

- Film material type

- Fully recyclable 100% paper film

- Control system

- Remote HMI control

- Label feature

- Pre-cuts for individual package separation

- Biscuit handling

- Careful handling to minimize damage

- Automation level

- Fully automated

- Sustainability

- 100% recyclable packaging

- Packaging speed

- Up to 70 meters/min

- Flexibility

- Adjustable biscuit pile sizes

- Error detection and rejection

- Automated sensor-based rejection

- Primary and secondary packaging

- Single and multipack capabilities

- Recyclability

- 100% paper

- Sustainability

- Fully recyclable film

- Adhesive compatibility

- Paper adhesive labels

- Environmental impact

- Reduces packaging material usage

- Recyclability Standard

- 100% paper recyclable

- Machine footprint

- Compact design for space efficiency

- Discharge method

- Infeed conveyor and race track system

- Stack formation

- Up to 10 biscuit piles

- Material and construction

- 100% recyclable paper

- Control panel type

- HMI control with remote management

- Film usage

- Up to 70 meters per minute

- Packaging type

- Primary and multipack packaging

- Programming Flexibility

- Piles of 4 to 10 biscuits

- Control Method

- Remote control via HMI

- Integration Options

- Flow pack and labeling synchrony

- Film Type

- 100% recyclable paper

- Label Type

- Adhesive paper labels