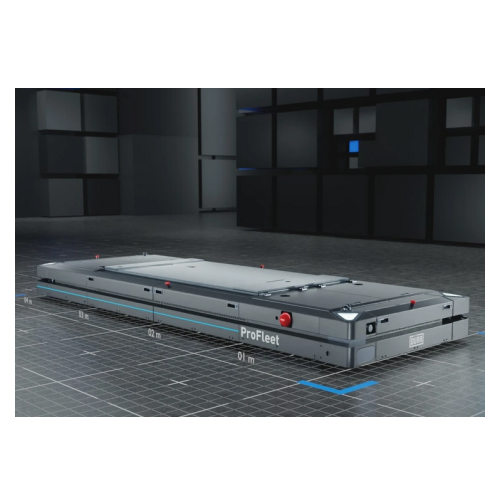

Automated guided vehicle for heavy load transport

Optimize your production flow with a robust solution for efficiently transporting and handling heavy components, ensuring seamless integration with existing systems and maximizing operational uptime.

Transports and Manages Diverse Industrial Loads

The ProFleet series from Dürr offers versatile and efficient automated guided vehicles (AGVs) tailored for industrial material handling and transport. Designed for applications ranging from automotive to heavy machinery, these AGVs excel in transporting, lifting, and towing tasks across diverse industries. Featuring models like the compact ProFleet 200 for lighter loads and the robust ProFleet X4 6000 for heavy-duty applications, this series adapts to various operational needs, including continuous operation and energy-efficient movements. Integrating seamlessly into production lines, these AGVs facilitate high-precision assembly, kitting, and synchronizing operations, boosting overall productivity. With options for rapid charging and customization, such as integrated cobots and lifting systems, the ProFleet AGVs are engineered to meet specific manufacturing demands while ensuring ergonomic operation and efficient workflow integration.

Benefits

- Enhances production efficiency with reduced handling time and seamless integration into existing systems.

- Lowers operational costs through energy-efficient motors and rapid charging capabilities.

- Supports ergonomic work environments with adaptable lifting mechanisms and customizable configurations.

- Increases operational flexibility with models catering to various load capacities and industry applications.

- Facilitates continuous and reliable operations, minimizing downtime and maximizing productivity.

- Applications

- Industrial equipment, Vehicle bodies, Electric vehicle components, Powertrains, Fabric reels, Heavy machinery, Mechanical parts, Paper reels, Automobile components, Household appliances, Batteries

- End products

- Car doors, Electric motors, Refrigerators, Transmission systems, Washing machines, Electric vehicle batteries, Newsprint rolls, Truck bodies, Heavy-duty engines, Car engines, Textile rolls

- Steps before

- Component preparation, Load assembly, Material handling

- Steps after

- Final assembly, Quality inspection, Packaging, Distribution

- Input ingredients

- trolleys, drive trolleys, small components, medium-weight loads, vehicle bodies, small and medium-weight components, tooling plates, large and heavy components, mechanical parts, battery, vehicle components

- Output ingredients

- transported materials, efficient intralogistics, line feeding operations, automated kitting, assembly processes, marriage final assembly

- Market info

- Dürr is known for its expertise in industrial engineering and manufacturing solutions, specializing in automotive painting technology, environmental technology, and production efficiency systems. It has a strong reputation for innovation and quality in engineered-to-order equipment.

- Load Capacity

- 200 kg – 4, 200 kg

- AGV Type

- ProFleet 200, 800, 1000, 2000, 3000, 4200, X2 4200, X4 6000

- Towing Pin

- Available

- Kinematics

- Tricycle, differential, omnidirectional

- Dimensions

- Length up to 3, 370 mm

- Ergonomics

- Ideal conditions, scissor lift

- Energy Solution

- Fast-charging capacitors

- Automation

- Synchronized with conveyors

- Mobility

- Highly agile, advanced maneuvers

- Lifting System

- Electromechanical, electrohydraulic

- Payload capacity for personnel

- 500 kg per platform

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Batch vs. continuous operation

- Batch / Inline Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Application Area

- Intralogistics / Assembly Line

- Load Type

- Trolleys, Boards, Devices, Vehicle Bodies

- Machine Footprint

- Varies by model (e.g., ProFleet 3000

- Load Capacity

- 200 kg to 6, 000 kg

- AGV Type

- Tricycle / Differential / Omnidirectional Kinematics

- Customization Options

- Scissor lift, Lifting Devices, Hydraulic Clamping, Engine Stands

- Dimensions

- Varies by model

- Charge Method

- Capacitor (Quick Charge)

- Control Panel Type

- Integrated AGV control systems

- Discharge Method

- Tug Pin / Towing Pin

- Configuration

- Narrow Design (ProFleet 3000), Slender Design (ProFleet 1000)

- Ergonomic Features

- Low Height Design, Scissor Lift for Ergonomics

- Integration possibilities

- Compatible with stationary units, other conveyors, and ProFleet solutions

- Control system

- PLC-controlled

- Kinematics type

- Tricycle or differential, omnidirectional

- Lifting device

- Scissor lift, electromechanical lifting systems

- Towing pin

- Available in different models

- Accessory compatibility

- Hydraulic clamping devices, engine stands, tilt tables

- Payload capacity adjustments

- 200 kg to 6, 000 kg

- Charging system

- Quick-charging capacitors