Vial and bottle cleaning system for pharmaceutical use

Ensure pharmaceutical-grade cleanliness for your vials, ampoules, and bottles with innovative wet cleaning technology that integrates smoothly into your production line, optimizing water and air use while maintaining rigorous compliance with industry standards.

Cleans and Prepares Pharmaceutical Containers

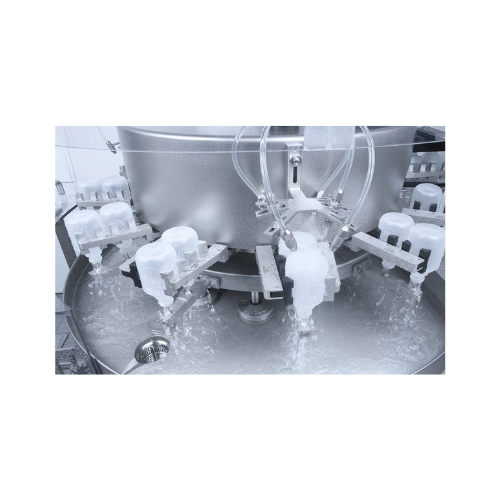

The FAW Series Wet Cleaning Machines from Bausch+Ströbel are engineered for meticulous cleaning of pharmaceutical containers, including vials, bottles, and ampoules. These machines feature a pressure-controlled rinsing and spraying system, enabling thorough cleansing without the risk of media mixing. With a processing capacity of up to 13,300 items per hour, they efficiently handle diverse container sizes. Designed for easy integration into high-speed production lines, the FAW machines incorporate ultrasonic pre-cleaning and optional ECOwash technology, cutting water and air consumption significantly. Constructed to meet GMP and FDA standards, they ensure compliance with strict industry regulations, while various customization options, like additional blow-cleaning stations and silicone treatment systems, allow tailored solutions for specific production needs.

Benefits

- Ensures pharmaceutical-grade cleanliness while minimizing the risk of contamination.

- Increases operational efficiency with a customizable cleaning process.

- Reduces resource use with up to 40% less water consumption.

- Enhances production flexibility by accommodating various container sizes.

- Compliant with GMP and FDA regulations, ensuring industry-standard quality.

- Applications

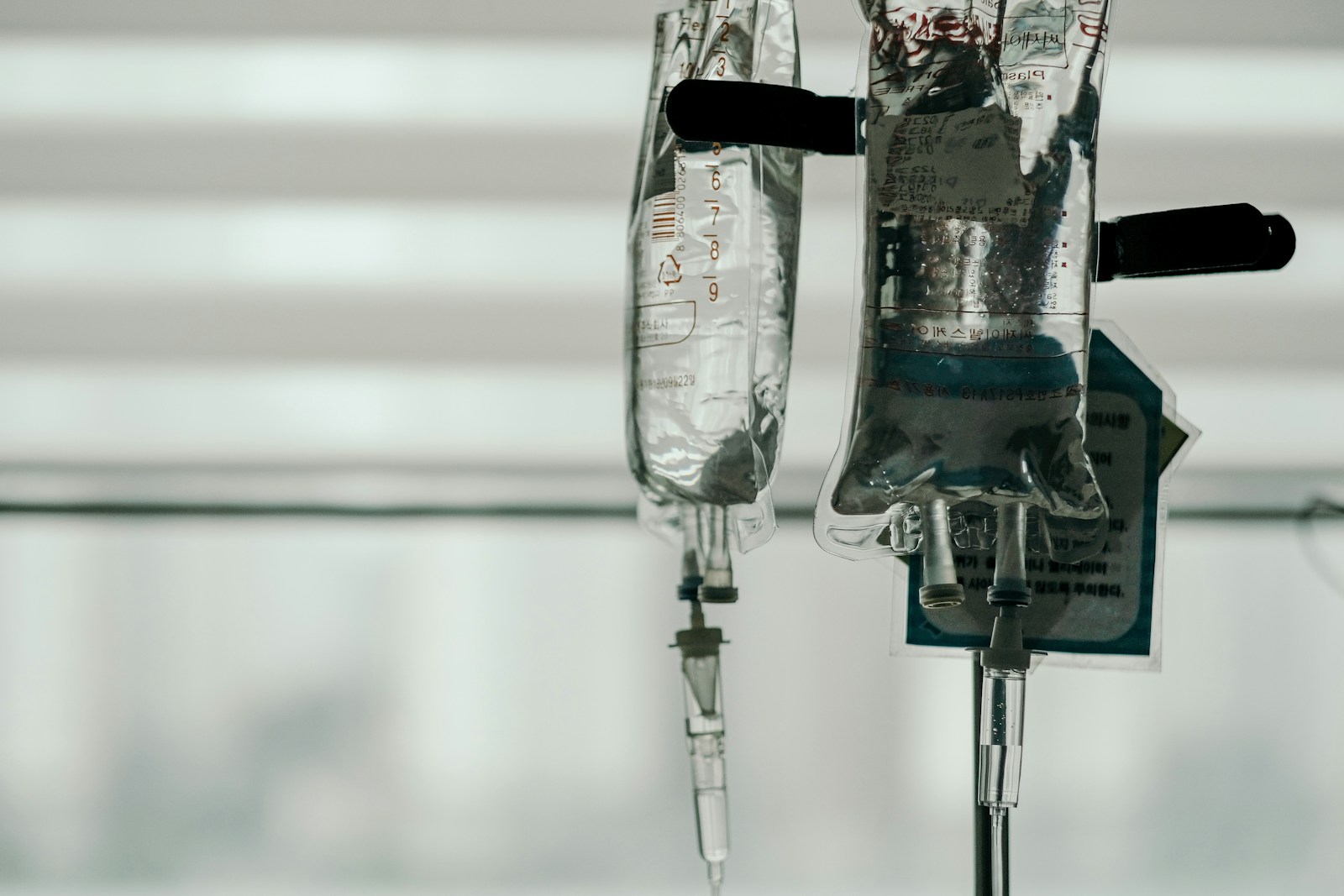

- Blood plasma, Liquid formulations, Vials, Biopharmaceuticals, Ampoules, Bottles, Pharmaceuticals

- End products

- Adrenaline ampoules, Nutritional liquids, Intravenous fluids, Antibiotic vials, Vaccines, Albumin bottles, Heparin vials, Injectable drugs, Blood serum, Sterile saline solutions, Biological samples

- Steps before

- Purification, Container Preparation

- Steps after

- Sterilization, Packing, Downstream Processing, DHT series, Sterilizing Tunnel

- Input ingredients

- vials, bottles, ampoules, non-stable containers, cleaning media

- Output ingredients

- cleaned containers, cleaned vials, cleaned bottles, cleaned ampoules

- Market info

- Bausch Stroebel specializes in manufacturing high-quality pharmaceutical packaging and processing machinery, renowned for their precision, reliability, and innovation in filling and packaging lines for the pharmaceutical industry. They are respected for tailored solutions and advanced engineering.

- Output

- up to 13, 300 items/h

- Container diameter

- 7.5 - 95 mm

- Container height

- 22 - 250 mm

- Cleaning method

- Pressure-controlled rinsing and spraying

- Cycle valve purging

- Yes

- Booster pumps

- Available

- Compressor unit

- Oil-free air supply

- Temperature monitoring

- Available

- Pressure monitoring

- Available

- Heating option

- Continuous flow water heater

- Filtration type

- Fine and HEPA filters

- Differential pressure monitoring

- For filters

- CIP version

- For media-carrying parts

- CIP/SIP version

- For fine and HEPA filters

- Electric heater

- For ultrasonic bath and water recycling station

- Mobile version

- Available

- Working mechanism

- Wet cleaning with intermittent flow

- Integrated steps

- Ultrasonic pre-cleaning, pressure-controlled rinsing, blow-cleaning

- CIP/SIP

- CIP version for media-carrying parts, CIP/SIP version for fine and HEPA filters

- Automation level

- Easy and centralized operation

- Batch vs. continuous operation

- Intermittent flow

- Energy efficiency

- High energy efficiency, reduced air and water consumption

- Changeover time

- Short set-up time

- Cleaning method

- Pressure-controlled rinsing, ultrasonic pre-cleaning

- Capabilities

- Container-optimized cleaning, non-stable container cleaning

- Batch documentation

- Meets GMP and FDA 21 CFR Part 11 guidelines

- Cleanability

- Pharma-compliant

- Corrosive resistance (e.g. acids)

- Yes

- Biological compatibility

- GMP compliant

- Abrasion resistance

- Moderate

- Density/particle size

- Adaptable for various container sizes

- Container type

- Vials / Bottles / Ampoules

- Cleaning method

- Wet cleaning

- Container stability

- Stable / Non-stable

- FDA Guidance Compliance

- 21 CFR Part 11

- Compact footprint

- Mobile version available

- Control panel type

- Centralized operation

- Discharge method

- Gentle container transport

- Cleaning media order

- Freely selectable

- Additional cleaning stations

- Container exterior blow-cleaning

- Cleaning station options

- Water recycling station

- Cleaning needle technology

- ECOwash optimized

- Cleaning of glass walls

- Silicone treatment system

- Optional extras

- Booster pumps, Compressor unit

- Temperature monitoring

- Available

- Pressure monitoring

- Available

- HEPA filter options

- Available

- CIP/SIP versions

- Available

- Mobile version

- Available