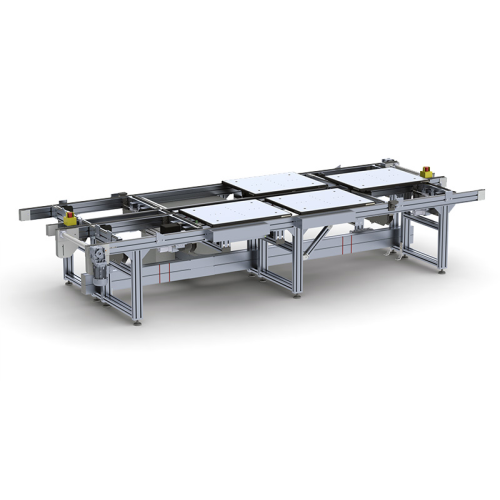

Twin track conveyor for heavy load applications

Handle complex assembly and testing needs with precision; this robust twin track conveyor excels in managing heavy, large-sized products efficiently, ensuring seamless flow across diverse production scenarios.

Conveys and Positions Heavy Industrial Products

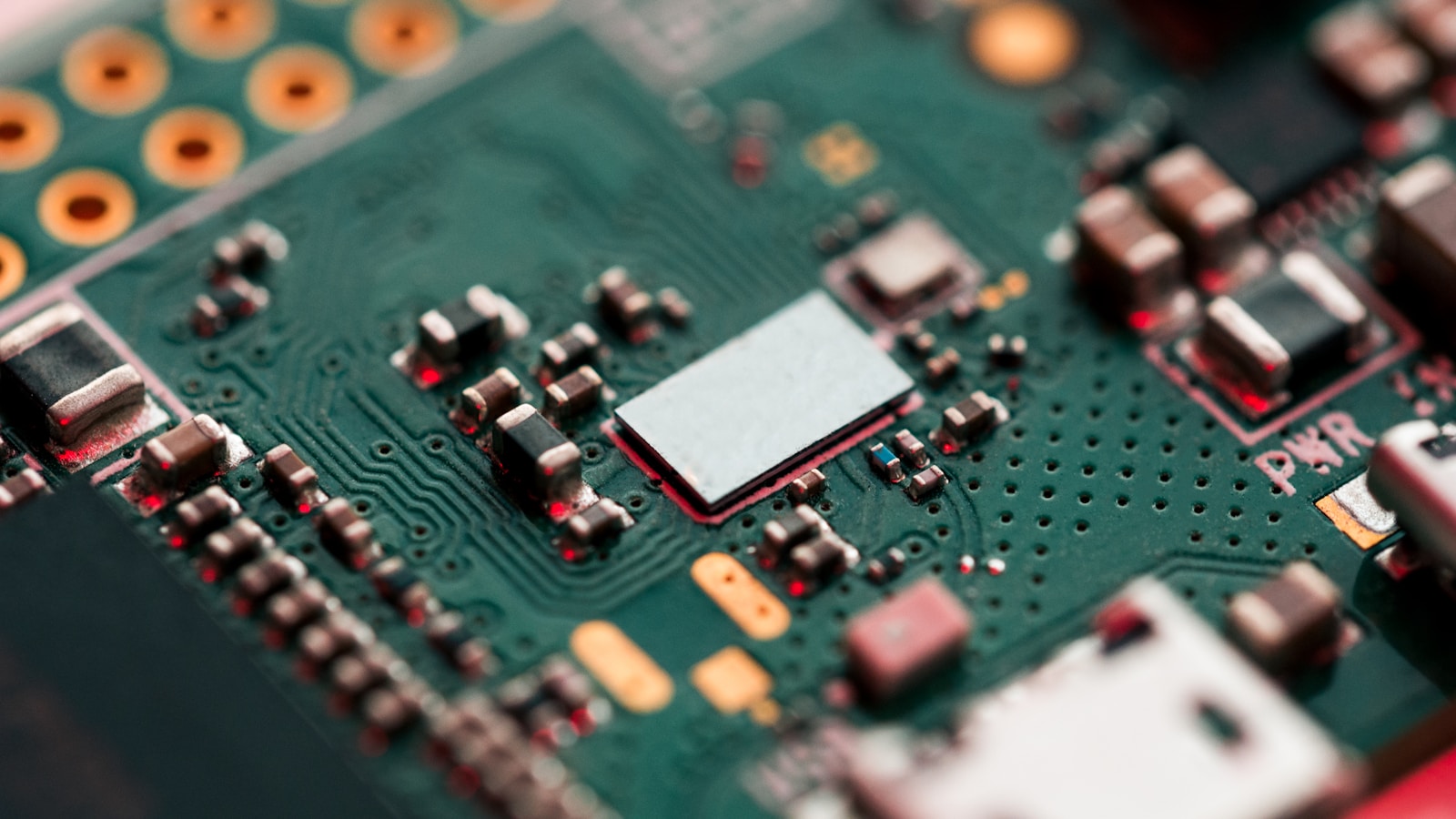

The HU Twin Track Pallet Conveyor System from FlexLink handles heavy industrial products with precision and efficiency. Specially designed for electronics, pharmaceutical, and automotive industries, this conveyor system supports product assemblies, from circuit boards to large machinery parts. Leveraging pre-defined control logic and RFID identification, it ensures seamless integration into production lines with one-piece track-and-trace capability. With a standard pallet width of 1040 mm and handling weights up to 200 kg, it accommodates a variety of product sizes and weights. The system’s modular configuration allows for adaptable layouts, facilitating routing, balancing, and buffering. Operating efficiently at up to 15 m/min, it offers robust performance while maintaining energy efficiency. Constructed with stainless steel options, it provides excellent corrosion resistance, catering to environments ranging from -20 to +60°C. Maintenance and cleaning are streamlined, ensuring minimal downtime in continuous, high-speed operations.

Benefits

- Enhances production efficiency with precise routing and positioning.

- Integrates seamlessly into existing lines with configurable modules.

- Supports heavy and large products, reducing manual handling.

- Ensures traceability with RFID-enabled pallets.

- Operates effectively in diverse environments, minimizing downtime.

- Applications

- Heavy-load products, Pharmaceutical products, Industrial goods, Electronics, Automotive parts

- End products

- Smart home devices, Vehicle engine components, Circuit boards, Medical syringes, Precision machining tools, Large machinery parts, Gear assemblies, Tablet bottles

- Steps before

- Assembly preparation, Initial product loading, Product sorting

- Steps after

- Testing, Quality control inspection, Final assembly, Packing

- Input ingredients

- heavy loads, individual products, product carriers, pallets, products ranging from a few grams up to 200 kg

- Output ingredients

- palletized products, assembled products, tested products

- Market info

- FlexLink (Coesia Group) is renowned for its innovative conveyor and automation systems, optimizing production efficiency for various industries such as food, automotive, and electronics, with a strong emphasis on modular and customizable solutions.

- Max speed

- 15 m/min

- Max product length

- 1040 mm

- Max product width

- 1040 mm

- Operating temperature

- -20 to +60 °C

- Chain type

- Roller-top chain

- Standard pallet width

- 1040 mm

- Product weight capacity

- up to 200 kg

- Automation level

- PLC

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- CE marking

- Yes

- ATEX certification

- Potentially relevant for ESD environments

- GMP Compliance

- Yes, applicable to Pharma, Healthcare

- FDA compliance

- Yes, suitable for clean product states

- Control panel type

- Pre-defined control logic

- Integration possibilities

- Configurable standard modules

- Product handling

- Pallet configuration

- Track-and-trace system

- RFID identification