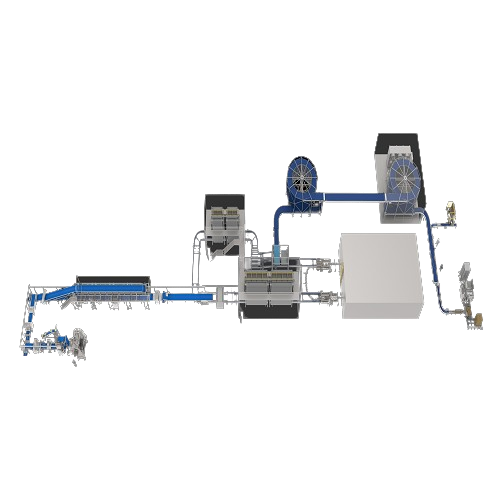

Danish and puff pastry production line

Enhance your pastry production with this integrated solution, designed to optimize the delicate processes of creating uniform, high-quality Danish and puff pastries, while ensuring seamless operation throughout your production line.

Processes and Automates Pastry Production

The Danish and Puff Pastry Production Line from AMF Bakery Systems offers a complete solution tailored for high-volume pastry manufacturing. This system specializes in automated sheeting, laminating, and baking processes, essential for producing European-style pastries such as Almond Danish and Chocolate Croissants. With capabilities to handle continuous, high-speed production, it enhances throughput while maintaining uniform product quality. Integrated with AMFConnect™ for real-time data access, the system optimizes operations and supports seamless integration into existing bakery environments. Designed for commercial bakery settings, the equipment features options for customizable configurations, energy-efficient operation, and easy-to-maintain components, ensuring reliable performance and reduced operational downtime.

Benefits

- Enhances production efficiency by enabling high-speed, continuous operation.

- Improves product consistency through precise sheeting and laminating capabilities.

- Increases operational decision-making with real-time data access via AMFConnect™.

- Reduces energy usage through optimized motor control systems.

- Requires minimal maintenance with its easy-to-clean, modular design.

- Applications

- Pastry products, Puff pastries, Sweet pastries, Croissants, Savory pastries, Danish pastries

- End products

- Vol-au-vent, Fruit tartlets, Sausage rolls, Butter croissant, Almond danish, Mille-feuille, Chocolate croissant, Spinach and feta puff pastry, Cheese danish

- Steps before

- Mixing, Dough Distribution, Dough Transport

- Steps after

- Proofing, Decorating, Baking, Cooling, Freezing, Handling, Palletizing

- Input ingredients

- dough, flour, butter, lamination ingredients

- Output ingredients

- Danish pastries, puff pastries, European-style pastries, decorated pastries

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Mixing Capacity

- Up to 3, 200 lbs

- Automation

- AMFConnect™ real-time monitoring

- Laminating Speed

- High-speed

- Oven Configuration

- Continuous

- Cooling Design

- Spiral Cooler

- Freezing Design

- Spiral Freezer

- Handling System

- Small footprint, air jet and vacuum system

- Conveyor Material

- Anodized aluminum beaded plates

- Operational Efficiency

- High

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- CIP

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Changeover time

- Fast setup

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Custom-configured to fit layout

- Construction material

- Stainless steel

- Feed method

- Dough elevator conveyor

- Discharge method

- Vacuum system depanner

- System integration

- Seamless integration with existing lines

- Control panel type

- Intuitive operations

- Customization options

- Scalable systems

- Cooling method

- Spiral cooler

- Freezing method

- Spiral freezer

- Control panel type

- AMFConnect™

- Integration possibilities

- Seamless integration

- Modular design

- Custom-configured