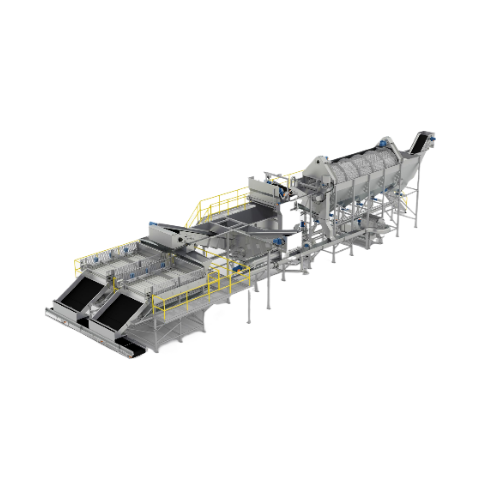

Industrial potato washing line

Optimize your potato processing with a versatile washing line that ensures thorough cleaning, reduces contamination risk, and integrates seamlessly into your continuous production flow.

Cleans, Destones, and Dries Root Vegetables

The Tummers Potato Washing and Destoning System offers a comprehensive solution for industrial food manufacturers seeking efficient cleaning and destoning of root vegetables. This system integrates a multi-stage process starting with the destoner/washer that uses upward water pressure for effective stone and clod removal. Following this, the drum washer with its unique design ensures thorough scrubbing of potatoes. The system is capable of 24/7 continuous operation, making it suitable for high-throughput environments in the food processing and potato industries.

Ideal for producing French fries, potato chips, and other processed vegetable products, it includes various specialized components such as floating parts removers and roller dryers to ensure clean, dry produce. This system requires minimal manual intervention through its PLC-controlled automation, ensuring seamless integration into existing production lines. Energy efficiency is achieved through optimized water and material usage, and the equipment is designed for easy maintenance and quick cleaning, ensuring maximum uptime and reliability in your operations.

Benefits

- Ensures consistent product quality with continuous 24/7 operation.

- Minimizes environmental impact by optimizing water and energy use.

- Integrates seamlessly into production lines for efficient processing of large volumes.

- Reduces manual labor with PLC automation and easy-to-use controls.

- Enhances sustainability efforts with low maintenance and high durability.

- Applications

- Agro-food products, Processed foods, Root vegetables, Potatoes

- End products

- Dehydrated potatoes, Potato flakes, Packaged root vegetables, Pre-washed potatoes, Potato chips, French fries

- Steps before

- Harvesting, Transport to facility

- Steps after

- Peeling, Cutting, Flaking, Frying, Packaging

- Input ingredients

- potatoes, stony soil, clods, stones, floating matter, green vegetation

- Output ingredients

- clean potatoes, dried potatoes, separated clods and stones, removed floating matter, removed green vegetation

- Market info

- Tummers is known for its expertise in manufacturing industrial engineered-to-order equipment, particularly for the potato processing industry, including peeling, cutting, and frying systems. They are reputed for innovation, quality, and customized solutions in food processing technology.

- Operation

- 24/7 operation

- Destoning method

- Water pressure and conveyor

- Washing system

- Blades and spinning drum

- Drying method

- Moisture absorbing felt rollers

- Material transport speed

- High speed

- Automation level

- Turnkey delivery, PLC-controlled

- Energy consumption

- Low (sustainable technology)

- Water consumption

- Low (sustainable technology)

- Failure rate

- Low

- Maintenance

- Low

- Destoning accuracy

- Efficient stone and clod removal

- Cleaning method

- Self-cleaning mechanism, potatoes rub against each other

- Working mechanism

- Destoning, washing, separating, drying

- Integrated steps

- Destoning, Washing, Separating floating matter, Drying

- Automation level

- High - suitable for 24/7 operation

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP (Clean-in-Place) compatible

- Energy efficiency

- Innovative sustainability focus

- Abrasion resistance

- High

- Biological compatibility

- Suitable for food processing

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Density/particle size

- Adaptable for various potato sizes

- Abrasiveness

- High/Low

- Pollution level

- Heavy/Light

- Moisture content

- High/Moderate/Low

- Foreign matter presence

- Floating/Heavy/Sinking

- End product type

- French fries / Flakes / Other

- Conveyor belt type

- Destoner/washer conveyor

- Drum shape

- Cylindrical spinning drum

- Discharge method

- Conveyor belt

- Control panel type

- HMI, touch screen

- Integration possibilities

- SCADA, PLC

- Machine configuration

- Turnkey, modular design

- Material handling

- Customizable destoning and washing stages

- Stage customizability

- Customizable washing stages and drying units