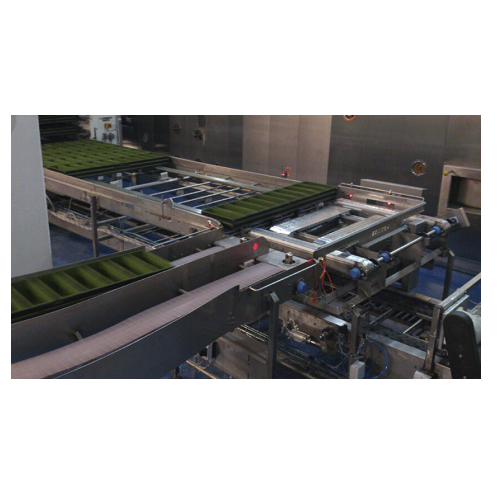

Industrial bakery conveying solutions

Ensure seamless, hygienic transport of bakery goods with precision-engineered conveying solutions that enhance production line efficiency and maintain product integrity from dough formation to final packaging.

Transports and Manages Bakery Product Flow

Radilinq Conveyor Systems from Rademaker are designed to optimize the transport of bakery products across processing stages, enhancing efficiency in both industrial and commercial bakeries. These systems specialize in precise and hygienic movement from dough preparation through to packaging. Utilizing a modular design, Radilinq offers three types of conveyors: Carrier, No Carrier, and Baked/Packaged Product Conveying, all supporting continuous and automated operations for a smooth production flow.

The Carrier Conveying system ensures stable transport on pan-straps, baking trays, or peel-boards, using specialized conveyors tailored for various line segments. The No Carrier system maintains dough integrity with positive driven belts and easy-clean components, accommodating various dough shapes even without carriers. The Baked/Packaged Product Conveying setups facilitate effective transitions to cooling and packaging areas via different belt types and programmable features.

Radilinq Conveyor Systems handle an extensive range of bakery products, such as artisan sourdough bread, flaky croissants, and glazed donuts, with configurations that ensure energy-efficient operation. Owing to its robust material choices and the potential for customization, the system fits seamlessly within diverse production environments, supported by engineering expertise and compliance with industry standards.

Benefits

- Enhances efficiency with seamless integration into existing production lines.

- Maintains product integrity and hygiene with easy-to-clean modular designs.

- Reduces operational downtime through reliable, continuous transport systems.

- Supports energy efficiency by optimizing motor control across conveyor segments.

- Offers customization options to fit specific bakery layouts and production needs.

- Applications

- Pie, Bread, Flatbreads, Laminated dough, Pizza, Croissants, Quiche, Pastries, Donuts, Bakery products, Bread and buns

- End products

- Baguettes, Plain bagels, Cream-filled pastries, Brioche rolls, Custard tarts, Glazed ring donuts, Pita bread, Savory meat pies, Thin-crust margherita pizza, Ciabatta bread, Vienna rolls, Deep-dish pizza, Puff pastry sheets, Naan bread, Danish pastries, Artisan sourdough bread, Flaky croissants, Chocolate-filled croissants, Spinach and cheese quiche, Hamburger buns, Focaccia bread, Fruit-filled pastries

- Steps before

- Dough make-up, Mixing, Laminating

- Steps after

- Depanning, Cooling, Packaging

- Input ingredients

- dough, pan-straps, baking trays, peel-boards

- Output ingredients

- baked products, packaged products, goods to cooling, goods to packaging areas

- Market info

- Rademaker is known for its expertise in manufacturing industrial bakery equipment, offering engineered-to-order solutions. They have a strong reputation for innovative, high-quality machines designed for efficiency and reliability in food production.

- Carrier Type

- Pan-straps, baking trays, peel-boards

- Conveyor Type

- Straight, curves, fixed position, programmable

- Hygienic Design

- Yes

- Belt Type

- Bar-belts, modular plastic belts

- Positive Driven Belts

- Yes

- Cleaning Method

- Easy-to-clean components

- Conveyor Material

- Aluminum profiles

- Control Type

- Standalone or complete line control

- Carrier Flow Regulation

- Sensors used

- Mobile or Fixed Units

- Available

- Transfer Units

- 90° transfer available

- Automation Level

- PLC-controlled

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Compact

- Conveyor Type

- Straight, Curved, Up-Down Units

- Material

- Aluminum Profiles

- Belt Type

- Modular Plastic Belts

- Design

- Hygienic, Easy-to-Clean

- Movement Control

- Programmable Fixed Position

- Discharge Method

- Pan-straps, Baking Trays, Peel-boards

- Carrier Type

- Carrier, No Carrier, Baked/Packaged Product

- Control Panel Type

- Touchscreen HMI

- Integration Possibilities

- Modular systems, PLC integration

- Conveyor Type

- Carrier, No Carrier, Baked/Packaged

- Belt Types

- Straight, Curves, Programmable

- Material of Construction

- Aluminum profiles

- Mobility

- Fixed or Mobile Units

- Line Control

- Standalone, Complete System

- Cleaning Design

- Hygienic Design, Easy-to-Clean