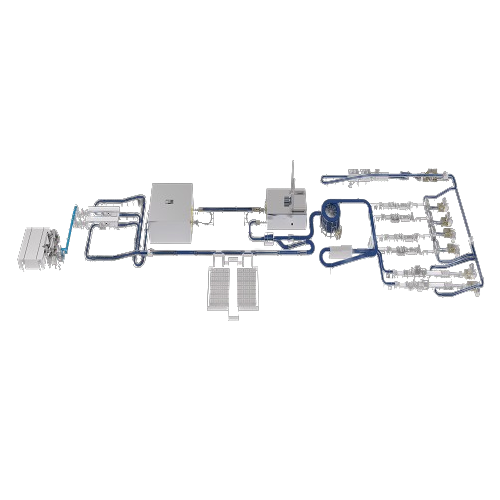

High-speed bun and roll production system

Optimize your bakery’s output with this high-speed system designed to streamline bun and roll production, ensuring consistency and efficiency while handling diverse dough types. Maximize your throughput and maintain top-tier quality with ease in large-scale operations.

Automates Mixing, Dividing, Proofing, and Baking

The High-Speed Bun and Roll Manufacturing System from AMF Bakery Systems is engineered to boost efficiency and output in industrial and commercial bakery settings. This system stands out with its fully integrated approach, automating key processes such as mixing, extruding, dividing, proofing, and baking. It operates on a continuous basis, seamlessly preparing products like hamburger buns, artisan breads, and pastries. With a production capacity of up to 96,000 units per hour, it meets the demands of high-volume production lines while maintaining product precision through AMF’s FLEX extrusion technology. The system’s PLCs offer real-time data access for monitoring and optimization, enhancing operational efficiency. Available with sanitary design options, it ensures hygiene compliance and ease of maintenance. Moreover, the robust configuration flexibility supports custom engineering solutions tailored to specific production needs, ensuring smooth integration into existing workflows.

Benefits

- Increases production capacity up to 96,000 units per hour, optimizing output efficiency.

- Enhances product quality consistency through precise AMF FLEX extrusion technology.

- Reduces operational costs by minimizing manual intervention with full automation.

- Offers real-time data access through PLCs, enabling informed decision-making and improved line efficiency.

- Ensures hygienic operation and easy maintenance with sanitary design options.

- Applications

- Buns, Hot dog buns, Muffins, Flatbreads, Baguette bread, Pizza, Pies, Puff pastry, Soft bread, Rolls, Cakes, Pastries, Croissants, Hamburger buns, Danish, Artisan bread

- End products

- Brioche rolls, Pain au levain, Pecan pie, Almond croissants, Slider buns, Puff pastry shells, Raspberry danish, Sponge cake, Sesame seed buns, San francisco sourdough, Baguette parisienne, Pretzel rolls, Whole wheat buns, Sourdough bread, Ciabatta bread, Multigrain baguettes, Chocolate muffins, Kaiser rolls, Napoli-style pizza crust, Hoagie rolls, Apple turnover, Soft hamburger buns, Focaccia flatbread, Blueberry muffins, Cheese danish

- Steps before

- Dough Mixing, Fermentation, Dough Chunking, Dough Feeding

- Steps after

- Proofing, Baking, Cooling, Packaging

- Input ingredients

- raw dough, dough chunks, fermented dough, dough ingredients

- Output ingredients

- buns, rolls, hamburger buns, hot dog buns, assorted rolls

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Production capacity

- Up to 96, 000 buns or rolls per hour

- Speed

- Up to 72, 000 pieces per hour (FLEX technology)

- Automation

- Fully automated

- Mixing capacity

- Up to 3, 200 lbs

- Conveyor design

- Bent plate structure for wash-down sanitation

- Product handling

- Gentle rotary blade and vacuum system

- Temperature control

- Individually programmed zones

- Bun packer capacity

- Up to 28 baskets per minute

- Dough transport capacity

- Up to 30, 000 lbs/hour

- Cooling solution

- Vesta Spiral Cooler

- Automation level

- Fully Automated

- Batch vs. continuous operation

- Continuous

- Changeover time

- Flexible and easy changeover

- Energy efficiency

- Industry-leading configurations

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Custom-configured to fit a variety of product applications

- Control panel type

- Advanced integrated real-time monitoring system

- Discharge method

- Sanitary, easy-access conveyors

- Machine footprint

- Flexible, multi-tier layouts

- Basket Stacker/Unstacker

- Handles up to 40 nested or cross-nested baskets per minute

- Modular Design Elements

- Custom-configured for Product Applications

- Cooling System Configuration

- Custom-configured Spiral Cooler

- Technology

- FLEX Extrusion Dividers