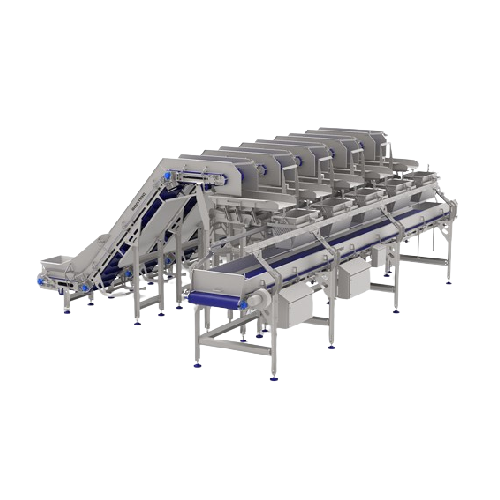

Automatic recipe conveyor for leafy vegetables

Streamline your vegetable processing with precise weighing and batching, ensuring uniform ingredient distribution and optimal mix consistency for salad and vegetable products.

Weighs and Mixes Vegetable Ingredients

The Automatic Recipe Conveyor RBA from Sormac is an engineered solution for precision weighing and mixing in vegetable processing. It operates through a central conveyor paired with weighing hoppers, utilizing vibratory feeders to ensure accurate batch weights. Ideal for producing salad mixes, coleslaw, and various leafy and cut vegetables, it handles between 300 kg to 3,500 kg/h. This equipment seamlessly integrates into both continuous and batch processing setups, supporting automation with pre-programmed ingredient control. Its design facilitates efficient ingredient deposition, minimizing waste and enhancing product consistency. The RBA is crafted for use in food processing environments, ensuring durability and operational efficiency, complemented by easy maintenance access.

Benefits

- Enhances product consistency with precise ingredient weighing and batching.

- Increases operational efficiency by handling up to 3,500 kg/h.

- Reduces waste through accurate ingredient deposition via vibratory feeders.

- Seamlessly integrates into existing processing lines for streamlined operations.

- Decreases manual intervention, cutting labor costs and minimizing human error.

- Applications

- Leafy vegetables, Cut vegetables

- End products

- Coleslaw, Lettuce mix, Cabbage slaw, Spinach portions, Kale salad blend, Shredded carrots, Mixed green salad, Salad mix

- Steps before

- Ingredient Preparation, Conveyor Belt Loading

- Steps after

- Batch Mixing, Salad Washing, Packing

- Input ingredients

- leafy vegetables, cut vegetables

- Output ingredients

- batched vegetable mixtures

- Market info

- Sormac is known for its expertise in manufacturing high-quality vegetable processing equipment, particularly peeling, washing, and slicing machines, with a strong reputation for innovation, reliability, and customer-focused solutions in the food processing industry.

- Capacity

- 300–3, 500 kg/h

- Batch size

- Customizable

- Automation

- Pre-programmed

- Weighing accuracy

- ±0.5–2%

- Conveyor belt type

- Central

- Vibration control

- Yes

- Working Mechanism

- Central conveyor belt with vibrating hoppers

- Integrated Steps

- Weighing, mixing, depositing

- Batch vs. Continuous Operation

- Batch

- Automation Level

- Automatic

- Batch Timing Control

- Adjustable based on capacity requirements

- Cleanability

- Easy to clean for food safety

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Biological compatibility

- Food contact safe materials

- Product type

- Leafy vegetables / Cut vegetables

- Discharge method

- Central conveyor belt

- Feed method

- Vibratory feeding to weighing hoppers

- Integration possibilities

- With preparation table, salad washer, washing flume

- Batch size customization

- 300 kg to 3, 500 kg/h

- Ingredient handling

- Vibrator supply system