Automatic weighing belt system for mixed products

Achieve precise control and seamless integration of product flows with a dynamic weighing belt system designed for continuous, high-capacity processing of mixed salads, vegetables, and fruits, optimizing your line for peak efficiency and quality output.

Controls and Weighs Mixed Product Flows

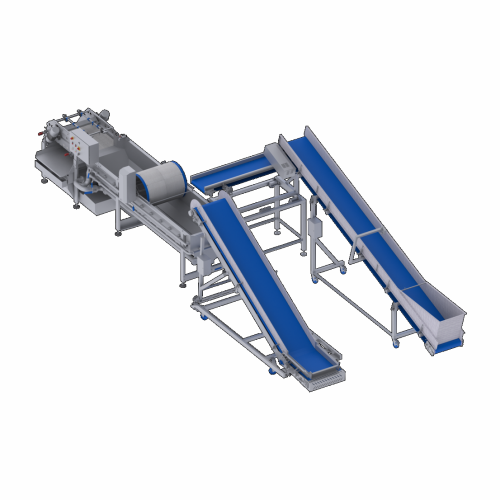

KRONEN’s Automatic Weighing Belt System revolutionizes the way you manage mixed product flows in salad and vegetable processing environments. This dynamic system controls and records the precise distribution and mixing of produce, integrating seamlessly into existing processing lines with ascending conveyor belt options for enhanced operation. Designed for applications like mixed salads, coleslaw, and fruit salad cups, it ensures accurate combination of components such as leafy greens and pre-cut vegetables.

Capable of processing up to 2,000 kg/h, this system is perfect for high-capacity, continuous operations. The integration of intelligent weighing belts guarantees exact product flow from start to finish, optimizing throughput and minimizing the need for manual intervention. Featuring SMART solutions, it offers remote monitoring capabilities and can be customized to specific production needs, making it adaptable for food processors, fresh produce distributors, and large-scale food manufacturers.

Constructed with easy-to-clean materials and designed with accessibility for maintenance, KRONEN’s system provides a compact and efficient footprint without sacrificing performance. Offering excellent energy efficiency and seamless integration into your processing line, it maintains the highest standards of hygiene and safety. With modular options available, you can tailor the system to your unique processing requirements.

Benefits

- Enhances accuracy in mixing with precise weight control, reducing product waste.

- Increases operational efficiency through continuous, automated processing.

- Customizable design adapts to specific line requirements, ensuring seamless production flow.

- Minimizes labor costs by automating product flow management.

- Compact footprint conserves valuable plant space while maintaining high capacity.

- Applications

- Mixed lettuce, Salads, Fruits, Cabbage mixes, Baby leaf salads, Vegetables, Leafy vegetables

- End products

- Baby spinach salads, Pre-packaged coleslaw, Fresh-cut leafy greens, Prepared cabbage slaw, Bagged mixed lettuce, Mixed salad bags, Fruit salad cups

- Steps before

- cleaning, cutting, pre-washing, trimming, sorting

- Steps after

- washing, mixing, drying, packing

- Input ingredients

- mixed lettuce, salads, vegetables, cabbage mixes, whole lettuce, leafy vegetables, fruit, baby leaf salads, pre-cut vegetable products, beetroot strips, carrot strips, cut iceberg lettuce, carrot sticks, chopped cabbage

- Output ingredients

- controlled product flow, precise mixing, mixed products, ensured continuous processing, recorded product flow, automatically processed lettuce and salads, weighed and mixed vegetables

- Market info

- KRONEN is known for manufacturing industrial food processing equipment, specializing in washing, cutting, peeling, and packaging machinery, recognized for innovation, high quality, and efficiency in automated food processing solutions.

- Automation

- Automatic weighing

- Capacity

- 2, 000 kg/h

- Weighing Accuracy

- Precise control

- Process Type

- Continuous

- Integration

- Compatible with washing and cutting machines

- System Design

- Flexible, customizable

- Loading Method

- Automatic and controlled infeed

- Component Addition

- Controlled via weighing belts

- Footprint

- Compact design

- Cleaning Access

- Easy access, foldable guides

- Dynamic Weighing

- Records and controls flow

- Output Management

- Recording at line end

- Automation level

- Automatic/Continuous

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Easy access/Manual

- Energy efficiency

- Optimized flow

- Dynamic weighing

- Control and record product flow

- Flexible design

- Customizable

- Continuous processing

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Small footprint due to integrated hopper and weighing belt

- Control panel type

- Digital control panel

- Discharge method

- Batch by batch discharge onto dosing belt

- Flexible design

- Variety of models available

- Integration possibilities

- Can be integrated with existing processing lines

- Control panel type

- Customized control options