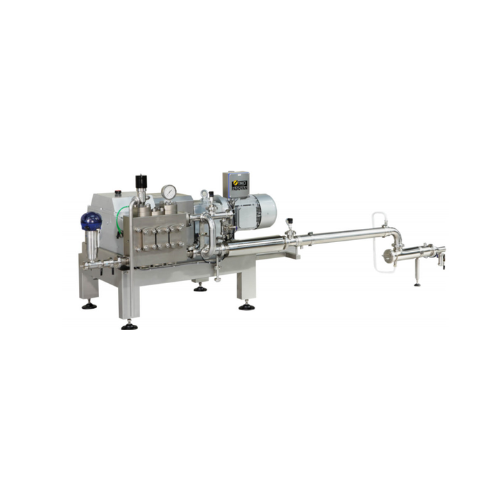

High pressure pumps for margarine production

Enhance your production line with high-pressure pumps designed for precise emulsification and pressure regulation in shortening and margarine processing.

Pumps and Emulsifies Shortenings and Margarine

The high pressure pumps from TMCI Padovan integrate seamlessly into food processing lines, effectively handling the emulsification of shortenings and margarine. Built with stainless steel and ceramic parts, these pumps are designed for hygienic operations, ensuring durability and corrosion resistance. They operate at pressures up to 200 bar and capacities ranging from 100 to 20,000 kg/hour, making them ideal for continuous operations in margarine and shortening production. Skid-mounted with pulsation dampers, pressure transmitters, and integral pressure relief valves, they offer advanced pressure management and safety features. These pumps are customizable to fit specific production requirements, and support continuous high-pressure operations in the food industry.

Benefits

- Ensures consistent product quality by handling emulsification under high pressure conditions.

- Increases operational efficiency with a wide capacity range up to 20,000 kg/hour.

- Enhances safety and reliability with integrated pressure relief and damping features.

- Maintains hygienic standards with corrosion-resistant stainless steel and ceramic components.

- Offers flexibility in production with customizable configurations for diverse processing needs.

- Applications

- Pastry products, Fats, Oils, Shortenings, Margarine, Bakery products

- End products

- Cooking oils, Spreads, Baking margarine, Frying fats, Cake shortenings, Puff pastry margarine, Croissant shortenings, Cookie dough fats, Margarine blocks

- Steps before

- Emulsification

- Steps after

- Packing

- Input ingredients

- shortenings, margarine emulsions

- Output ingredients

- processed shortenings, processed margarine emulsions

- Market info

- Pressure

- Up to 200 bar

- Capacity

- 100 to 20, 000 kg/hour

- Design

- Fully hygienic

- Material

- Stainless steel and ceramic product contact parts

- Mounting

- Skid mounted

- Operating pressure

- Up to 200 bar

- Flow rate

- 100–20, 000 kg/hour

- Pulsation control

- Pulsation dampers

- Pressure relief

- Integral pressure relief valves

- Skid mounted installation

- Yes

- Hygienic design

- Stainless steel and ceramic parts

- Abrasion resistance

- High

- Biological compatibility

- Food-grade materials

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel and ceramic

- Pump design

- Hygienic, stainless steel, ceramic contact parts

- Mounting style

- Skid mounted

- Pulsation dampers

- Included

- Skid mounting

- Available

- Pulsation dampers

- Included

- Pressure transmitter

- Integrated

- Pressure relief valves

- Integral

- Material of construction

- Stainless steel and ceramic